Automatic acid pickling production line control system

A technology of automatic production line and control system, which is applied to conveyor control devices, conveyor objects, conveyors, etc., can solve the problems of wet working environment, poor work visibility, and low labor operation rate of commuters, and achieves the labor intensity of employees. Low, high synchronization accuracy, high cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

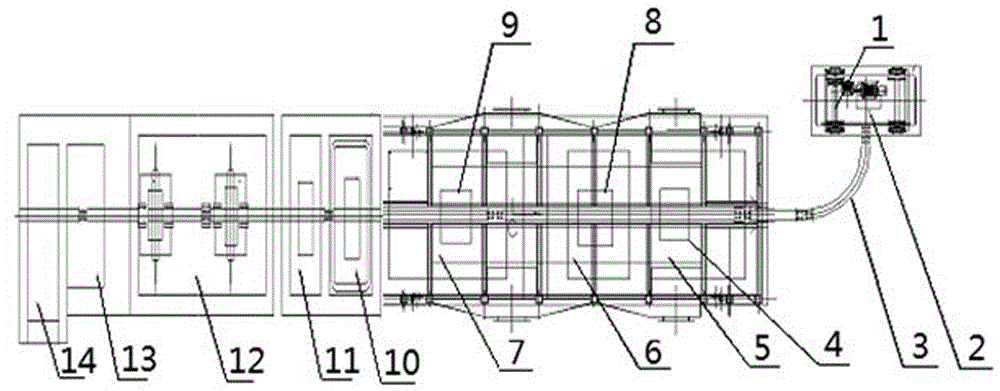

[0018] The following structural drawings describe in further detail a kind of pickling automatic production line control system of the present invention:

[0019] figure 1 Among them, the automatic pickling production line control system of the present invention consists of feeding trolley 1, I trolley 2, track 3, II trolley 4, I acid tank 5, II acid tank 6, III acid tank 7, III trolley 8, and IV Composed of trolley 9, high-pressure water tank 10, I clean water tank 11, phosphating tank 12, II clean water tank 13 and hot water tank 14; feeding trolley 1, track 3, I acid tank 5, II acid tank 6, III acid tank 7, High-pressure water tank 10, I clean water tank 11, phosphating tank 12, II clean water tank 13 and hot water tank 14 are arranged in sequence to form an automatic pickling production line control system, and I trolley 2 and I acid tank 5 are arranged on loading trolley 1 The II trolley 4 is configured, the III trolley 8 is disposed on the II acid tank 6, and the IV tro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com