Automatic deviation correcting method and system for linear travelling of RTG (Rubber-Tyred Gantry crane)

A technology of automatic deviation correction and straight-line walking, applied in the field of port machinery, can solve the problems of high work intensity, hidden safety hazards, and easy fatigue of drivers, and achieve the effect of reducing the probability of accidents, reducing labor intensity and increasing reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, various embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. However, those of ordinary skill in the art can understand that, in each implementation manner of the present invention, many technical details are provided for readers to better understand the present application. However, even without these technical details and various changes and modifications based on the following implementation modes, the technical solution claimed in this application can also be realized.

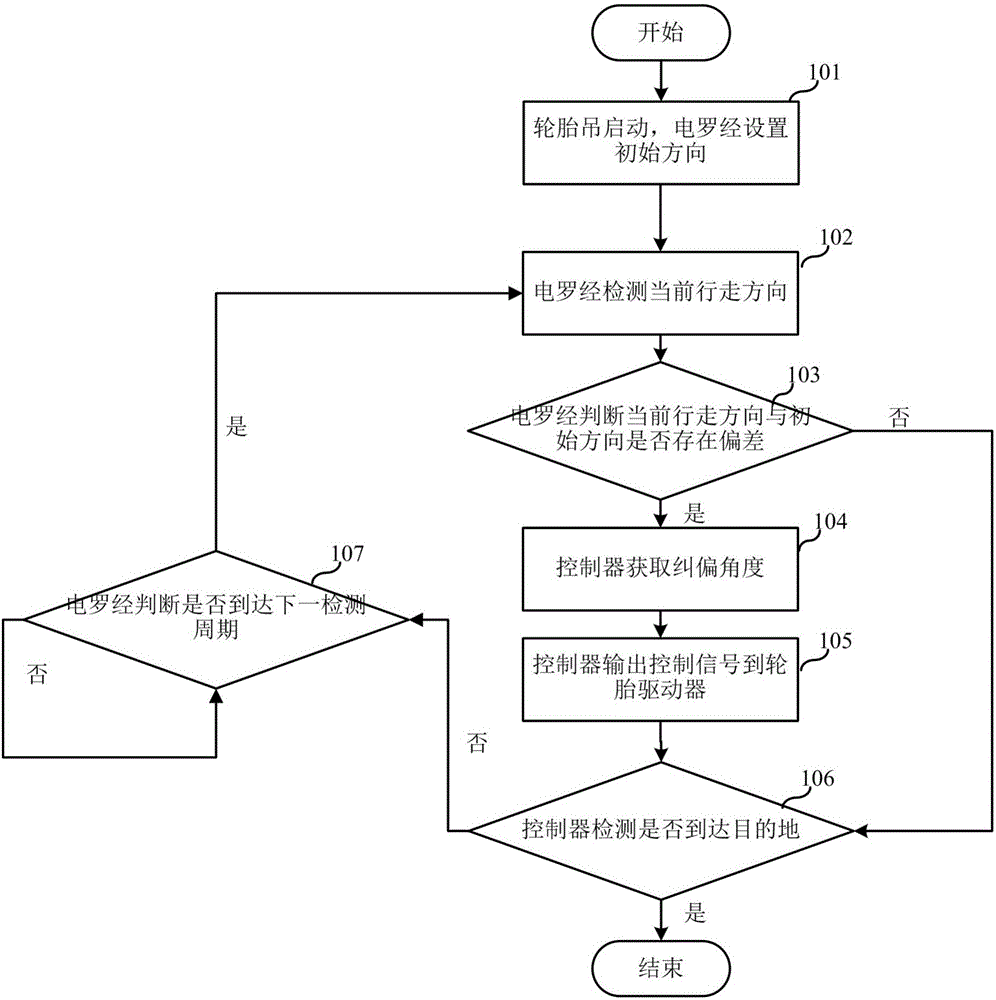

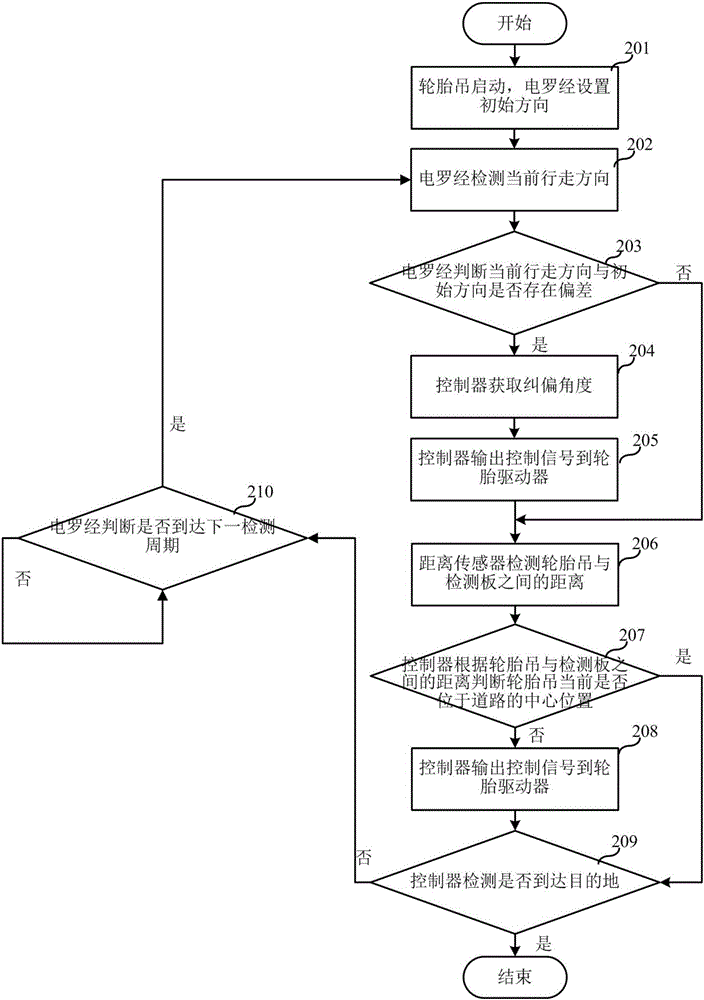

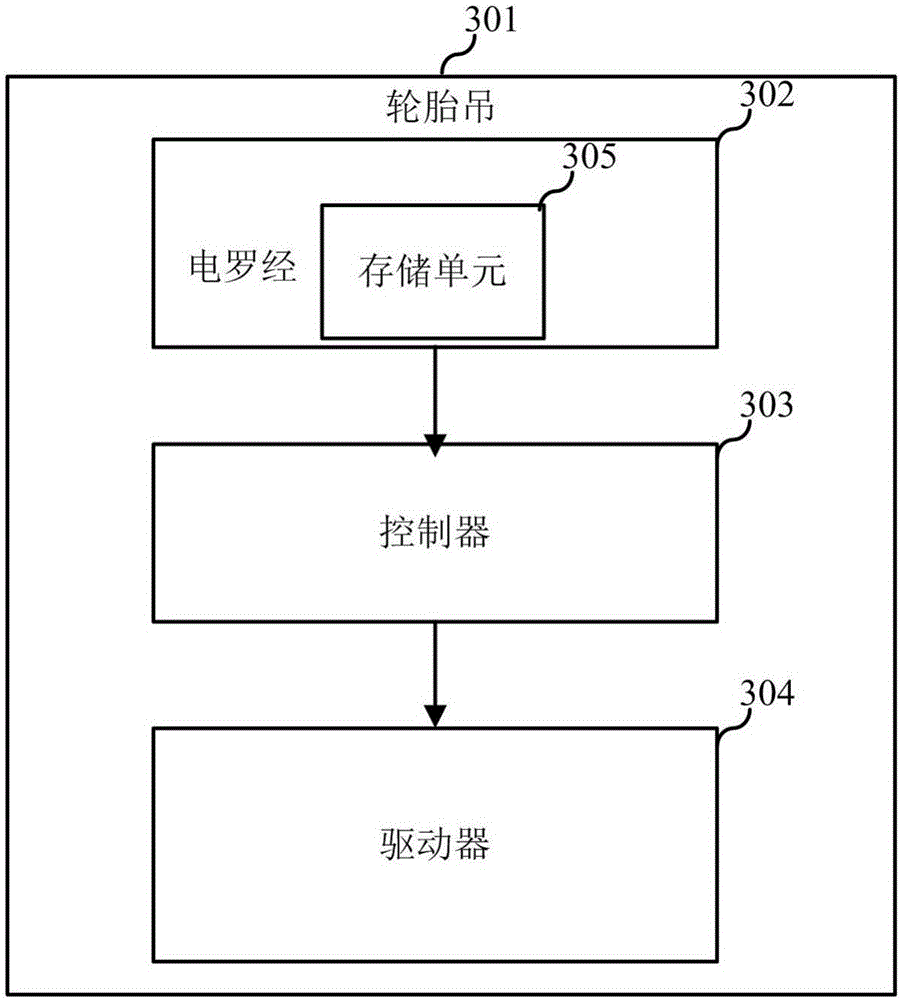

[0021] The first embodiment of the present invention relates to an automatic deviation correction method for a tire crane walking in a straight line. The walking direction of the tire crane is automatically judged by the gyrocompass. If there is a deviation between the walking direction of the tire crane and the original direction, the devia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com