Efficient air floating machine device

An air flotation machine, high-efficiency technology, applied in flotation water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., to achieve stable operation, improved water treatment effect, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

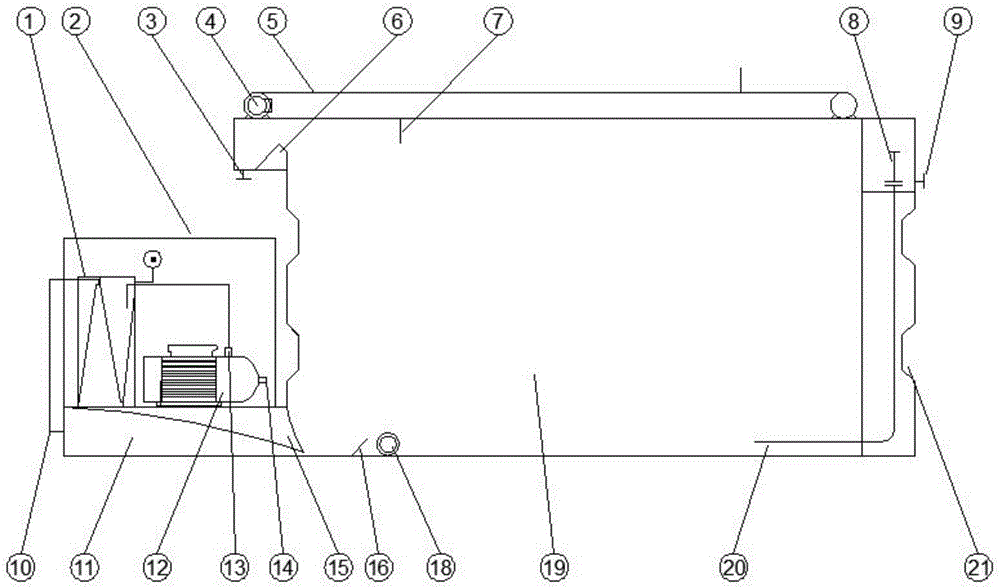

[0011] Such as figure 1 As shown, the present invention provides a high-efficiency air flotation machine device, including an air-water mixing device 1 and a water pump 12 positioned inside the power equipment box 2, and the water pump 12 is provided with a raw water inlet 14 and a raw water outlet 13. The raw water outlet 13 leads into the air-water mixing device 1, and the air-water mixing device 1 communicates with the main equipment 19 boxes through the water equalizing device 15. The bottom surface in the main equipment 19 is provided with a water-lifting baffle 16, and the The top of the main equipment 19 is provided with a slag scraper 4, the slag scraper 4 is provided with a corrosion-resistant chain 5, and the corrosion-resistant chain 5 is provided with at least one slag scraper 7, and the top of the main equipment 19 passes through The slag scraping port 6 is connected with the slag discharge port 3, and the bottom of the main equipment 19 is connected with the wate...

Embodiment 2

[0013] The raw water enters the water pump 12 from the raw water inlet 14 and enters the air-water mixing device 1 from the raw water outlet 13 under the action of the water pump 12. The raw water reacts in the air-water mixing device 1, and the raw water and air are fully mixed with air and water. The dissolved air water is formed, and the dissolved air water is evenly discharged into the main equipment 19 through the water equalizing device 15. The dissolved air water entering the main equipment 19 rises first under the action of the water lifting baffle 16, and the slag scraping is started. Machine 4, slag scraper 4 drives the corrosion-resistant chain 5 to rotate, so that the slag scraper 7 also moves with the corrosion-resistant chain 5, and the scum scraper 7 sends the scum floating on the water surface to the slag discharge through the slag scraper port 6 Finally, the scum is discharged from the slag discharge port 3, and the clean water at the bottom of the main equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com