A kind of magnetron sputtering device and magnetron sputtering method

A magnetron sputtering device and magnetron sputtering technology, applied in sputtering coating, metal material coating process, vacuum evaporation coating, etc., to achieve uniform deposition rate, high uniformity of film formation, and shorten production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and implementation examples. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0031] The present invention is described in conjunction with the following specific embodiments.

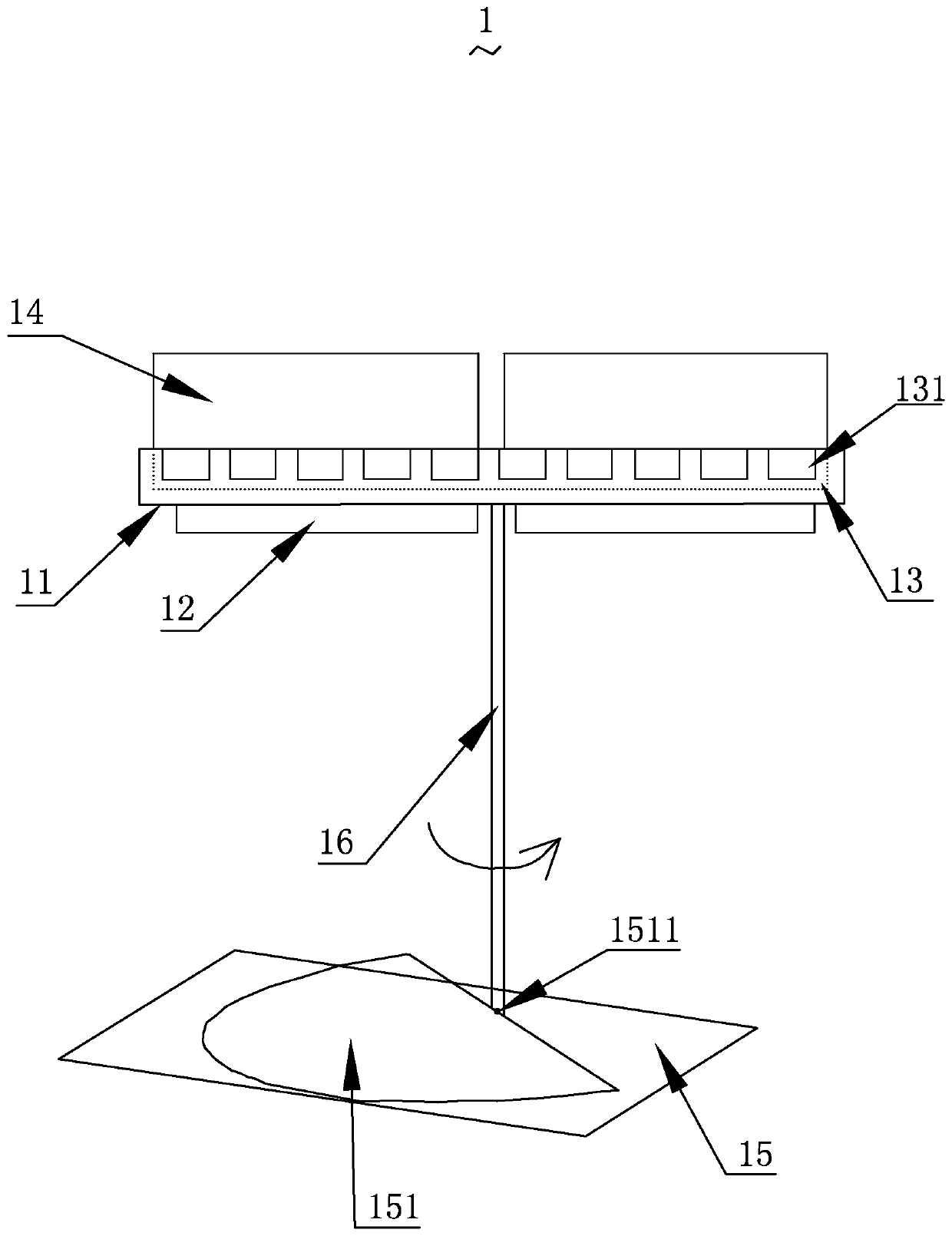

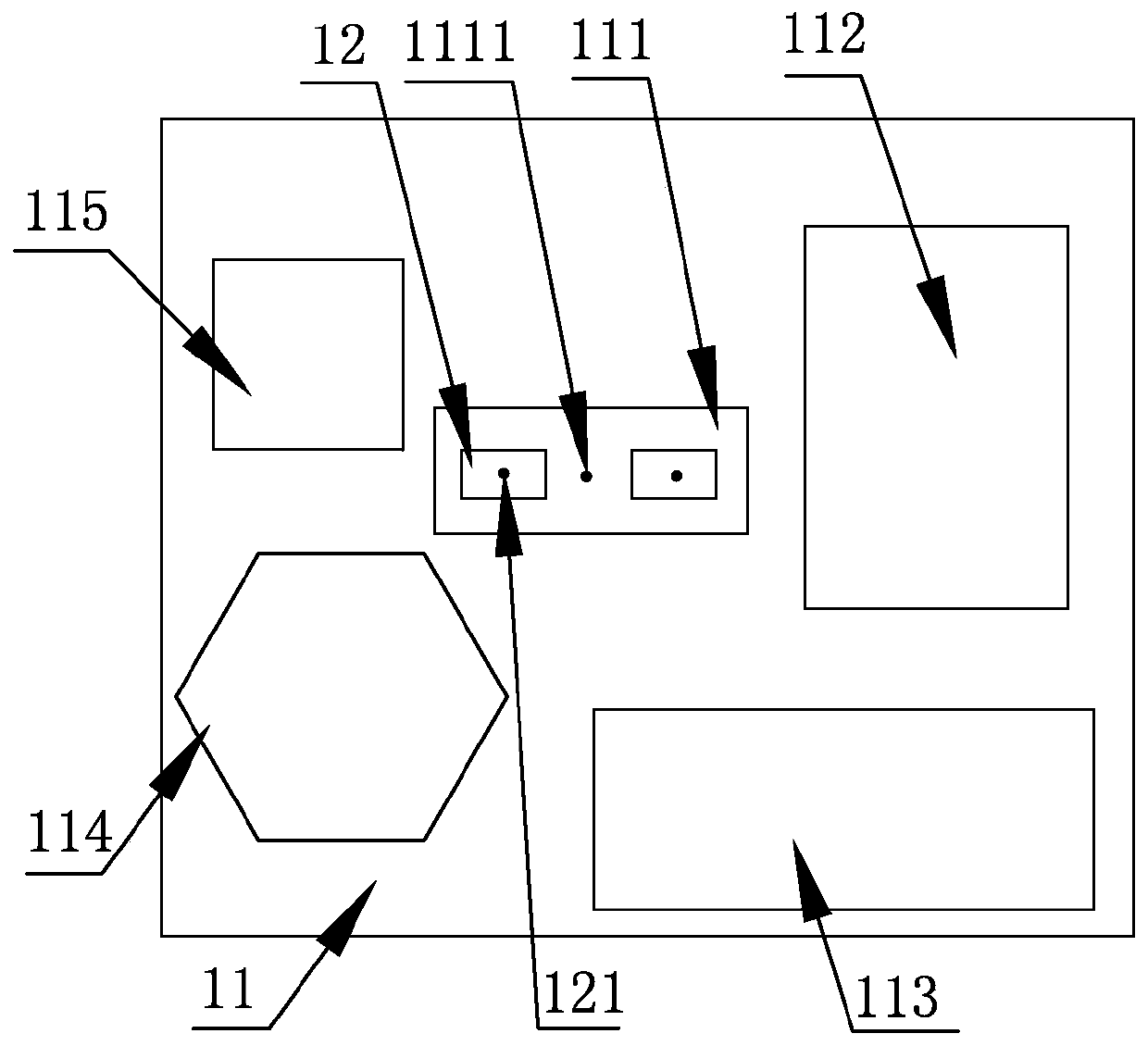

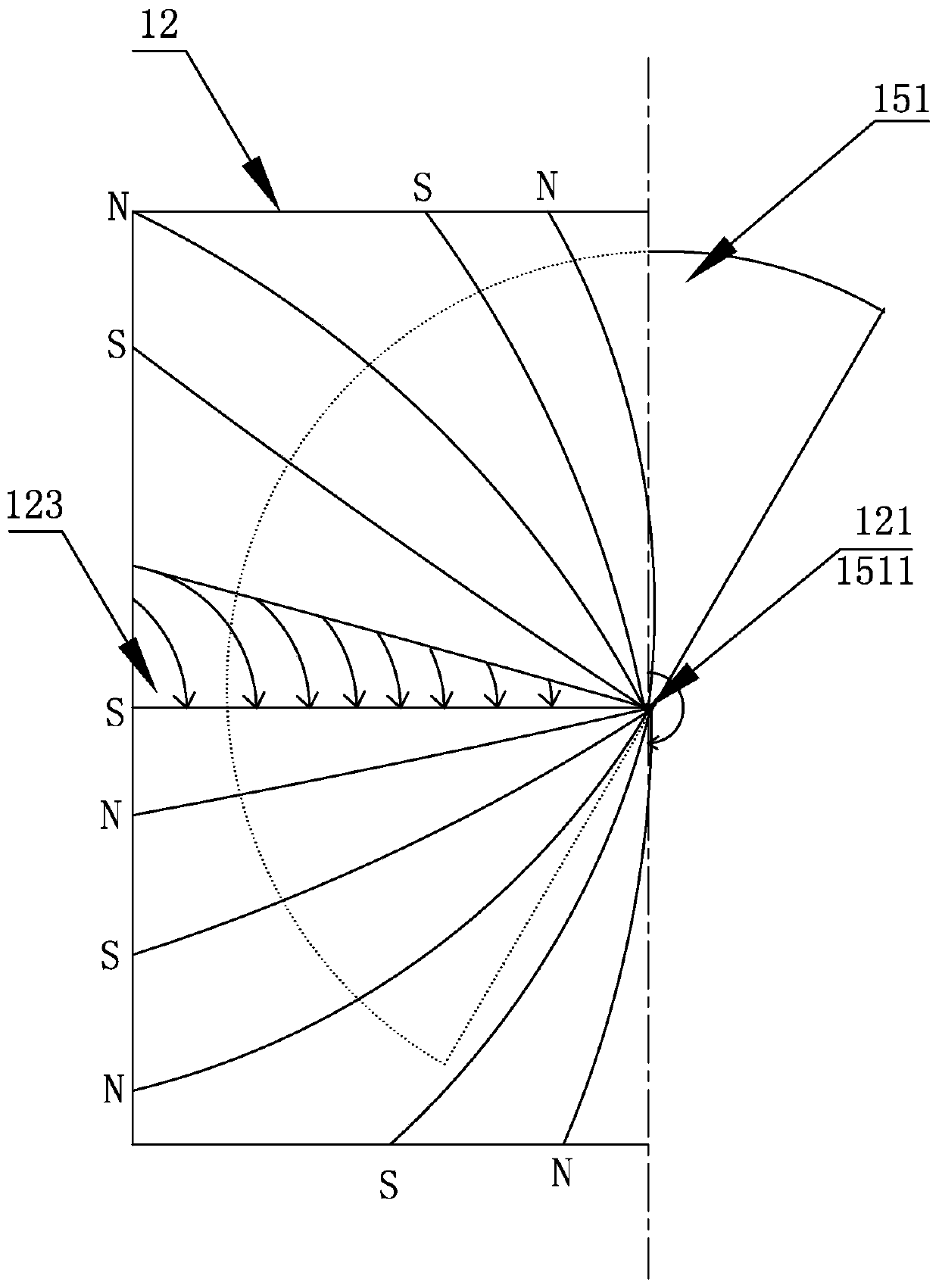

[0032] Please refer to figure 1 , The magnetron sputtering device 1 of the present invention includes a supporting mechanism 11, a target material 12, a magnetic force generating mechanism 13, a power source mechanism 14, a loading mechanism 15, a rotating mechanism 16 and a base 151. The target 12 is fixed on the supporting mechanism 11, and the supporting mechanism 11 houses the magnetic force generating mechanism 13. The power supply mechanism 14 is arranged on the supporting mech...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com