Novel rolling friction combined multilevel screw rod

A rolling friction, lead screw technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of reducing the torque transmission efficiency of the lead screw, unstable operation, unreliable transmission, etc., and achieve convenient and reliable assembly. The effect of reducing maintenance work and improving transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

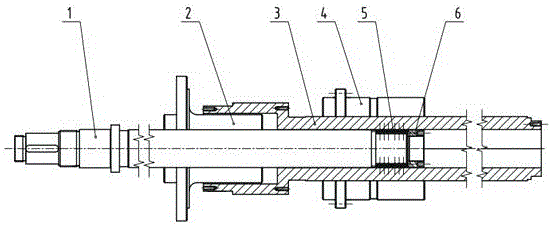

[0031] Such as figure 1 As shown, the new multi-stage screw with rolling friction combination has a two-stage screw structure, the second-stage screw is set outside the first-level screw, and adopts the structure of stacked sets, and each screw is equipped with a nut. It includes a primary lead screw (1), a primary nut (2), a secondary lead screw (3), a secondary nut (4), a polygonal rolling friction pair (5), and a lock nut (6). The polygonal rolling friction pair (5) adopts a regular hexagonal structure. Among them, the first and second screw screws can be screw screws of various specifications and types, such as trapezoidal screw screws, ball screw screws, and planetary roller screw screws.

[0032] The polygonal rolling friction pair (5) is installed on the rear end of the primary screw (1) and axially fixed by the lock nut (6). The rear end of the primary screw (1) adopts a regular hexagonal structure, and the secondary screw ( 3) The inner hole is also a regular hexago...

Embodiment 2

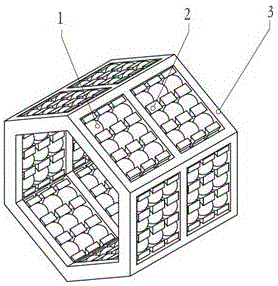

[0037] Such as image 3 As shown in , the new rolling friction combined multi-stage lead screw is a three-stage lead screw structure, the three-stage lead screw is stacked, and each lead screw is matched with a nut, including the first-stage lead screw (1) and the first-stage nut (2) , secondary screw (3), secondary nut (4), tertiary screw (5), tertiary nut (6), first polygonal rolling friction pair (7), first lock nut (8 ), the second polygonal rolling friction pair (9), and the second lock nut (10). The two polygonal rolling friction pairs are fixed on the rear end of the front-stage screw, and the fixing method adopts the inner and outer polygonal fit, and is axially positioned by the lock nut.

[0038] The primary nut (2) is installed on the primary screw (1), the inner ring of the first polygonal rolling friction pair (7) is installed on one end of the primary screw (1), and the first locking nut (8) For axial fixing, the outer ring is connected with the polygonal inner...

Embodiment 3

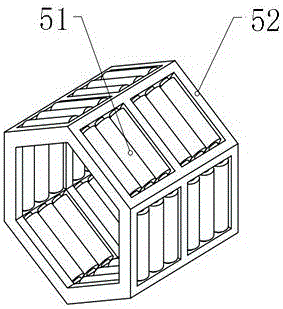

[0043] On the basis of the first embodiment, the roller structure in the polygonal rolling friction pair structure is replaced by a ball structure, and two polygonal rolling friction pairs are arranged between the primary screw and the secondary screw. The two polygonal rolling friction pairs are fitted and fixed on the primary lead screw respectively, and the two polygonal rolling friction pairs are matched with the inner hole of the secondary lead screw at the same time. Both the polygonal rolling friction pair and the inner hole of the secondary screw adopt a pentagonal structure. Two polygonal rolling friction pairs are fixed on the primary lead screw in the form of internal and external splines.

[0044] Figure 2B Middle: The polygonal ball friction pair consists of a polygonal protective frame (3), an inner cage (2), and balls (1). The balls (1) are spaced and evenly arranged by the inner cage (2), and the inner cage (2) is installed on the polygonal cage (3), and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com