Organic thermal carrier steam hot air combined thermal power cogeneration circulating fluidized bed boiler

A circulating fluidized bed and carrier technology, which is used in steam boilers, fluidized bed combustion equipment, steam generation, etc., can solve problems such as energy waste, large investment, and inability to coordinate energy adjustments, improve combustion efficiency, and increase furnace volume. , the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The device will be further described below in conjunction with the accompanying drawings and specific embodiments.

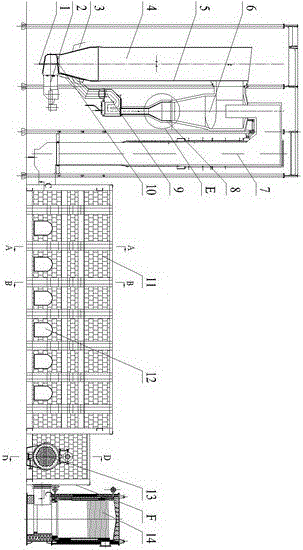

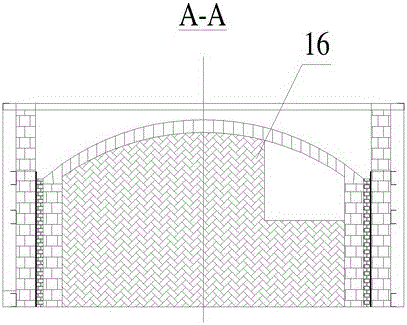

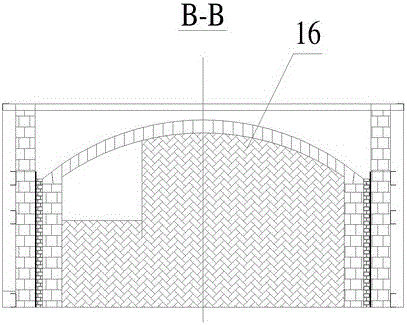

[0024] The invention is attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, a circulating fluidized bed boiler with organic heat carrier steam and hot air combined heat cogeneration is characterized in that it includes a circulating fluidized bed furnace body assembly 5, a high-temperature flue gas settling purification chamber 11, an organic heat carrier heating system 14, a steam Generator 13.

[0025]The circulating fluidized bed furnace assembly 5 includes a slag falling pipe 1, an equal pressure air box 2, a feeder 3, an air distribution plate 10, a furnace 4, an air-cooled wall 8, a high-temperature separator 6, a smoke duct 7, and a return material Device 9.

[0026] The high-temperature flue gas settling clean room 11 includes a clean room body 21, a dust removal port 12, a high-temperature fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com