A clean burning coal-fired circulating fluidized bed boiler

A circulating fluidized bed, coal-burning technology, applied in fluidized-bed combustion equipment, fuels burned in a molten state, combustion methods, etc. The effect of prolonging the service life and reducing the excess air factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The device will be further described below in conjunction with the accompanying drawings and specific embodiments.

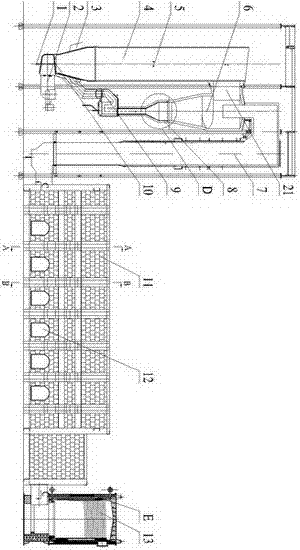

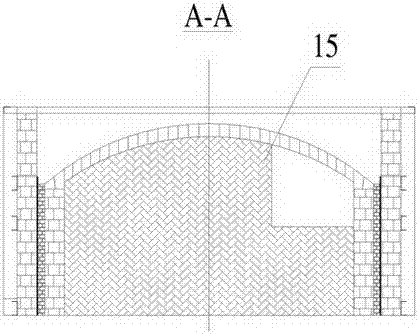

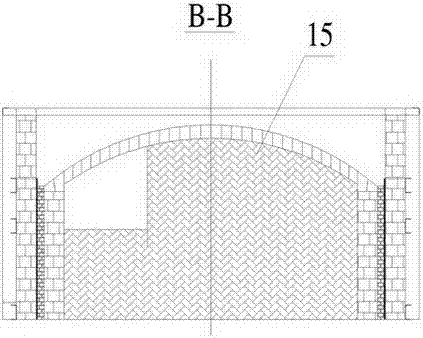

[0026] The invention is attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, a clean combustion coal-fired circulating fluidized bed boiler is characterized in that it includes a circulating fluidized bed furnace body assembly 21, a high-temperature flue gas settling purification chamber 11, a heat exchange system 13, and a calcium spraying system assembly 22.

[0027] The circulating fluidized bed furnace assembly 5 includes a slag falling pipe 1, an equal pressure air box 2, a feeder 3, an air distribution plate 10, a furnace 4, an air-cooled wall 8, a high-temperature separator 6, a smoke duct 7, and a return material Device 9, calcium spray hole 5.

[0028] The high-temperature flue gas settling clean room 11 includes a clean room body 20 , an ash removal port 12 , a high-temperature flue gas inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com