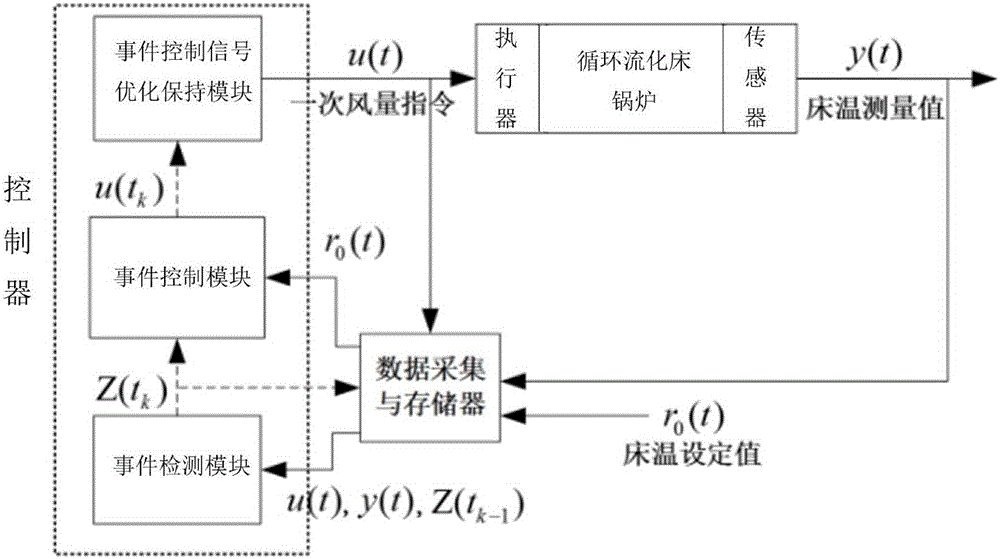

Circulating fluidized bed boiler bed temperature event-driven control system based on state feedback

A circulating fluidized bed, event-driven technology, used in fluidized bed combustion equipment, fuel burning in a molten state, lighting and heating equipment, etc., can solve high quality requirements, adverse effects of the original control system performance, complex design process And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

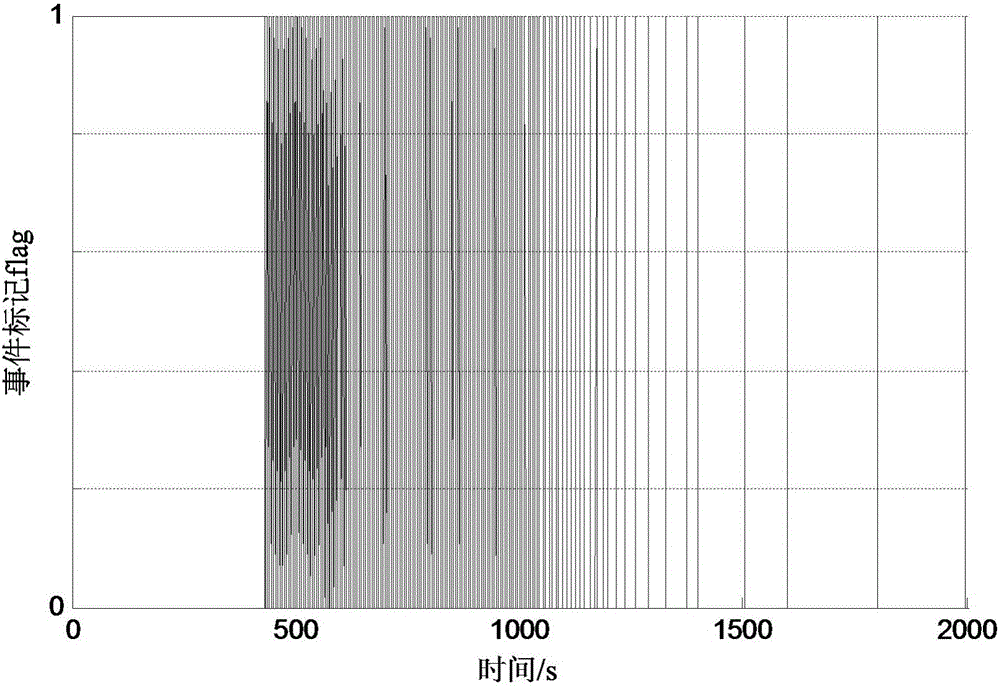

Examples

Embodiment 1

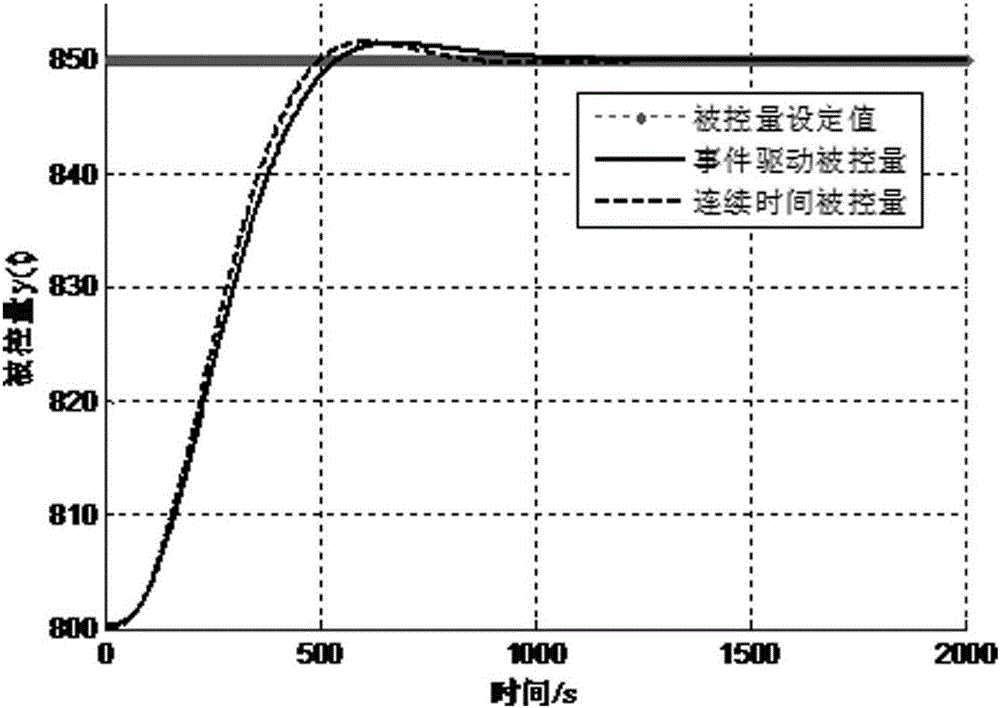

[0061] Assuming that the bed temperature of a circulating fluidized bed boiler is influenced by the primary air volume, the mathematical model is:

[0062] G ( s ) = y ( s ) u ( s ) = - 8.5985 ( 1 + 120.3560 s ) ( 1 + 95 s )

[0063] In the formula, s is the symbol of the Laplace operator, G(s) is the mathematical model of the transfer function of the bed temperature affected by the primary air volume, y(s) is the complex of the measured value y(t) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com