A dual cycle temperature and humidity control system

A temperature and humidity control, dual-cycle technology, applied in the field of control, can solve the problems of large fluctuations in the temperature and humidity of the return air flow, large equipment occupation and power consumption, and high operating costs. Low power and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the specific details of the present invention described below are only for illustrating the present invention, and do not constitute a limitation to the present invention. Any modifications and variations made in accordance with the teachings of the invention as described are also within the scope of the invention.

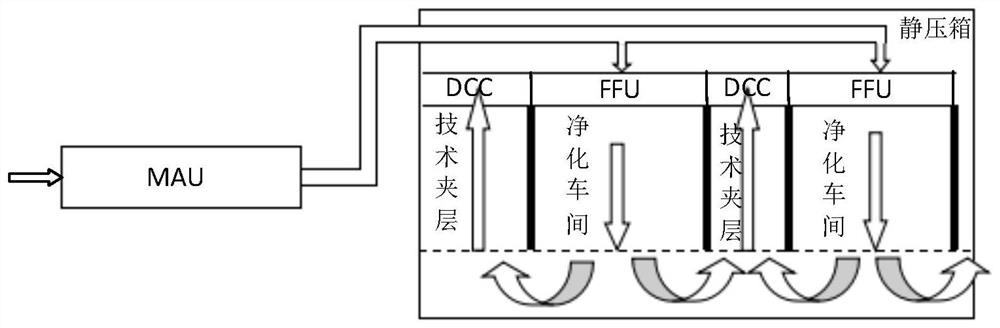

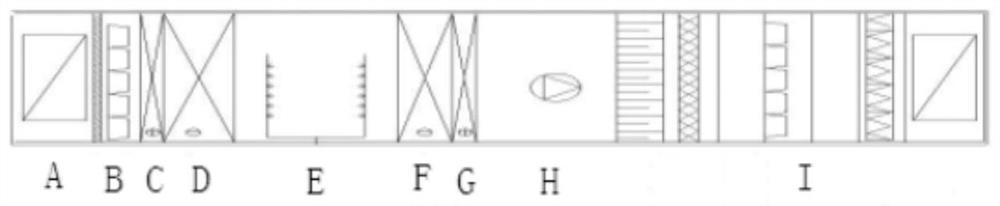

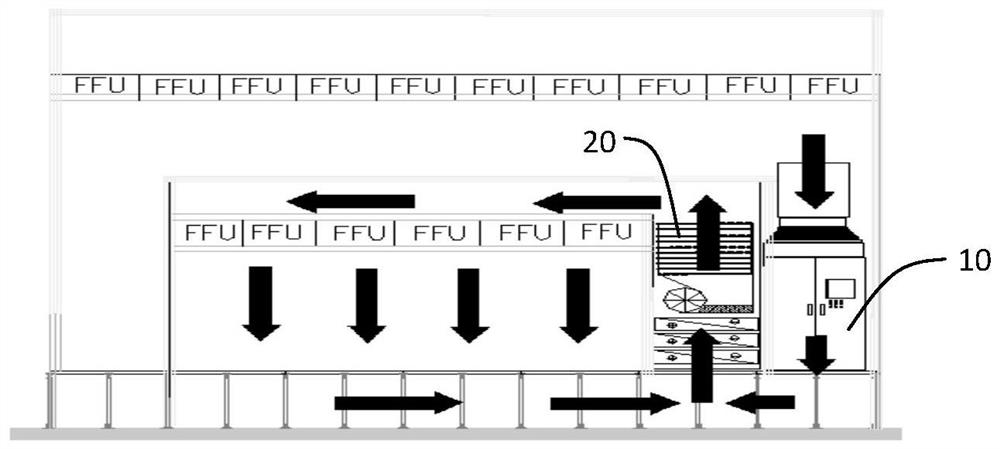

[0026] Such as figure 1 Shown is the principle diagram of the dual-cycle temperature and humidity control system provided by the present invention. It can be seen from the figure that multiple purification workshops are included in the purification plant, and an upper interlayer is included on the top of the purification plant; the dual-cycle temperature and humidity control system It includes a fresh air unit, multiple fan filter units and multiple dry pipe coils. Among them, the fresh air unit is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com