Novel special sheath pipe for pigtail

A sheath tube, a new type of technology, applied in the direction of fiber mechanical structure, light guide, optics, etc., can solve the problems of difficult operation and pigtail penetration, achieve reasonable structure, improve the aesthetics of the deployment process, and avoid wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

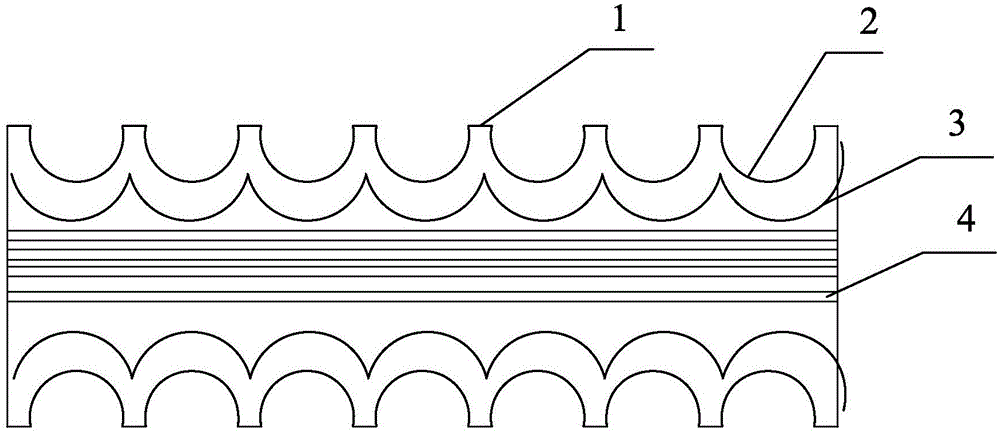

[0014] Such as figure 1 The pigtail special-purpose sheath tube shown includes a tube body 1, and a plurality of indentations 2 are evenly arranged side by side on the tube wall of the tube body 1, and an adhesive layer is evenly adhered to the wall of the indentation 2. A plurality of guide wire tips 3 are pasted, and the guide wire tips 3 protrude out of the tube wall.

[0015] The pipe wall is made of transparent material.

[0016] The middle part of the pipe body is provided with eight through holes 4, and the ends of the through holes 4 are colored.

[0017] Connect the exposed end of the pigtail that needs to be protected with the guide wire head 3, and then pull the exposed end of the pigtail into the tube body 1 through the wire guide head 3, which can be classified into different through holes 4 according to the type of pigtail Inside, the colors of the through holes 4 can play a role in indicating respectively.

[0018] The above-mentioned implementation cases are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com