sheet metal bending machine

A bending machine and metal sheet technology, applied in the field of bending machines, can solve problems such as time required, and achieve the effect of quick installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

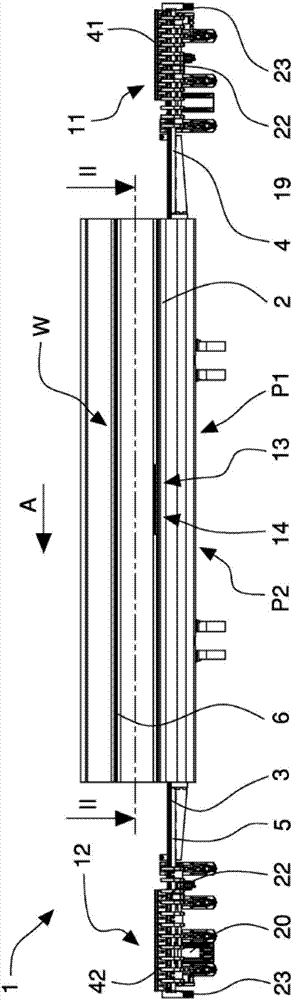

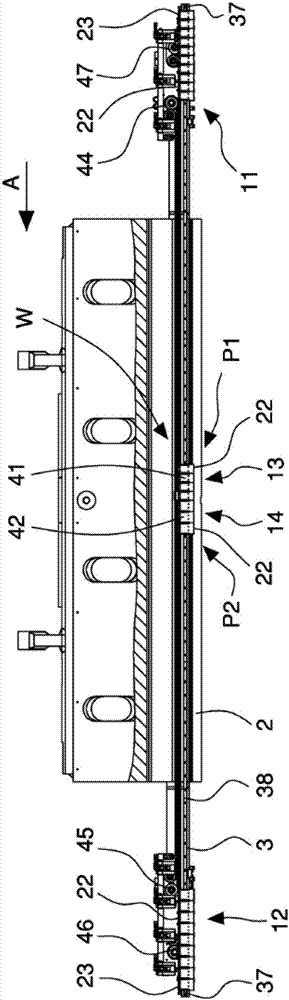

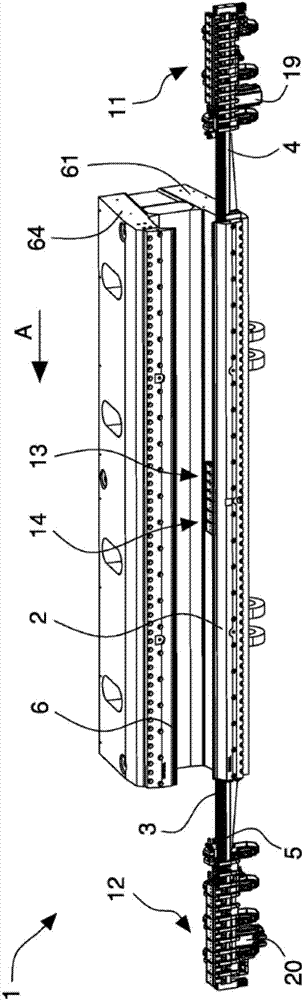

[0035] refer to Figure 1 to Figure 21 A sheet metal bending machine 1 for processing sheet metal components according to the invention comprises a main bending tool member 2 extending along the longitudinal direction A and movable for deforming and bending a workpiece 50 . In the embodiment of the machine shown in the figures, the main bending tool member 2 comprises a bottom or lower linear bending tool which is hinged to the frame 68 of the machine 1 by means of a lower support 61 and is movable about a first axis X1 Rotate so as to contact the workpiece 50 from bottom to top. The axis X1 is horizontal and parallel to the longitudinal direction A. The workpiece 50 is fixed and fastened by the clamping members 62 , 63 . The clamping member comprises an upper clamping member 62 that moves vertically with respect to a fixed lower clamping member 63 forming a support surface B for the workpiece 50 ( Figure 7 ).

[0036] The main bending tool member 2 and clamping members 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com