Patents

Literature

53results about How to "No reduction in output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

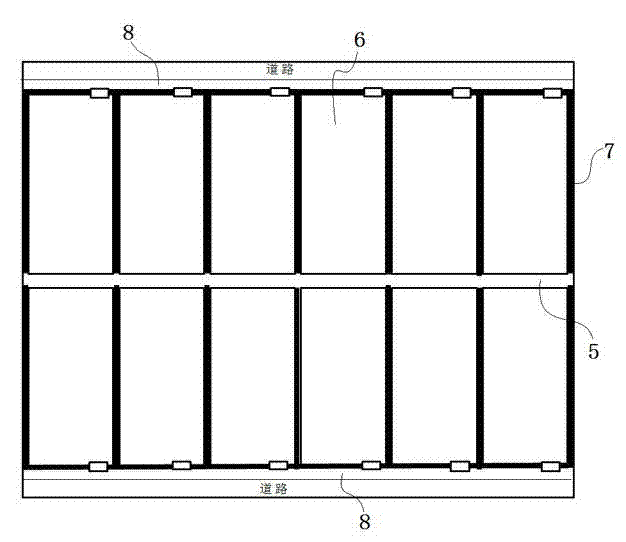

Rice field ditch integrated ecological high-value rice and soft-shelled turtle planting and breeding method

ActiveCN103027008AReduce areaReduce outputAnimal feeding stuffRice cultivationEconomic benefitsPaddy field

The invention discloses a rice field ditch integrated ecological high-value rice and soft-shelled turtle planting and breeding method which comprises the following steps: 1, ruralizing a rice field and installing fences; 2, plowing the rice field; 3, transplanting rice; 4, putting soft-shelled turtles in the rice field and raising the soft-shelled turtles; 5, conducting field management; and 6, harvesting the rice and the soft-shelled turtles in good time. The method has the advantages that: 1, the foundation works of the rice field is optimized without reducing the area of the rice; 2, the foundation works of a rice ditch is optimized without destroying the structure of the rice field; 3, the landscape of the rice field is optimized to provide a good growth environment for the soft-shelled turtles; 4, a ladder type culture method is adopted to increase the planting and breeding density; and 5, the economic benefit of the rice field in a unit area is greatly increased.

Owner:HUNAN AGRICULTURAL UNIV

Method for cultivating oyster mushrooms at bottoms of tea-oil trees by taking tea-oil tree nutshells as major raw materials

InactiveCN102613000ASimple processEasy to implementHorticultureEcological environmentCamellia oleifera

The invention relates to the technical field of edible mushroom cultivation, in particular to a method for cultivating oyster mushrooms at the bottoms of tea-oil trees by taking tea-oil tree nutshells as major raw materials. The method particularly comprises the following steps: preparing culture medium by taking the tea-oil tree nutshells as the major raw materials, building cultivation beds at the bottoms of all tea-oil trees in the forest ground of the tea-oil trees for cultivating the oyster mushrooms, and planning to seed at the beginnings of February and October every year, when the temperature is appropriate and rainy seasons are avoided; and the fruiting begins at the ends of March and November; and the method further comprises a building method of the cultivation beds, a seeding method, management methods for the mycelium culture process and fruiting, and the like. By implementing the method, the soil yield rate, the resource utilization rate and the agricultural labor productivity can be increased; the soil conditions can be improved, and the growth of fruit trees and the protection of the ecological environment can be facilitated; with the adoption of the cultivation mode, farmers can realize a stereoscopic agriculture production mode without increasing any investment or reducing the output of other crops, and the fruits and the mushrooms are rich in harvest.

Owner:何寒

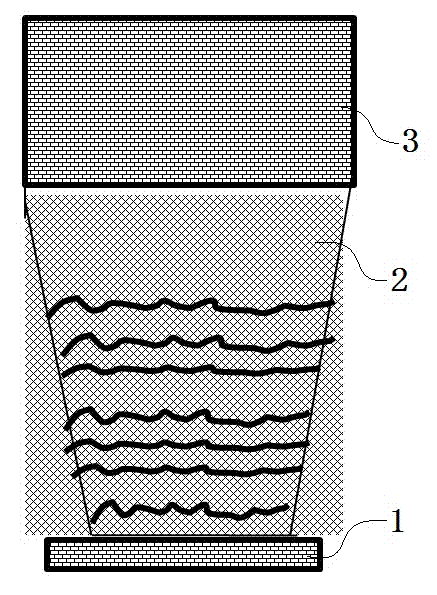

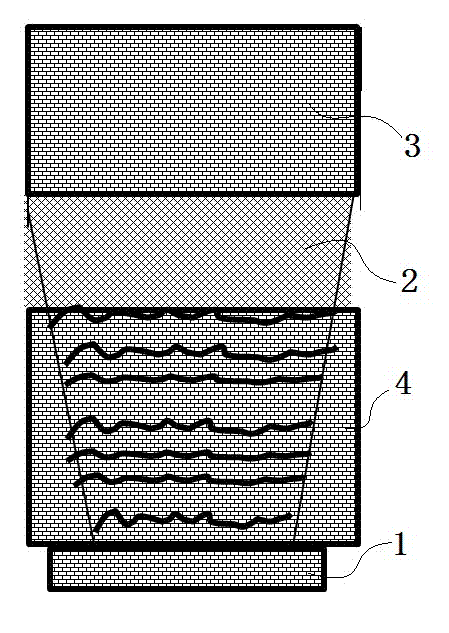

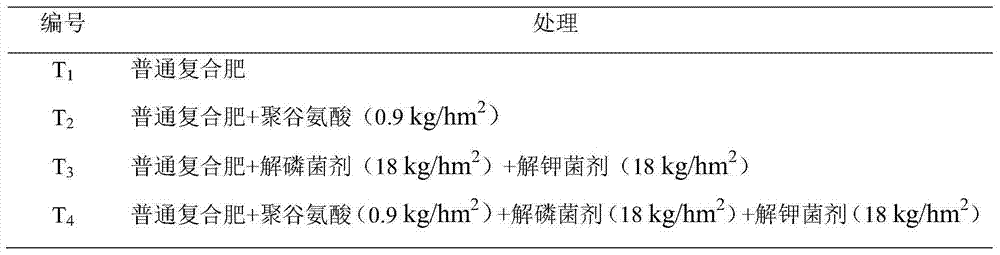

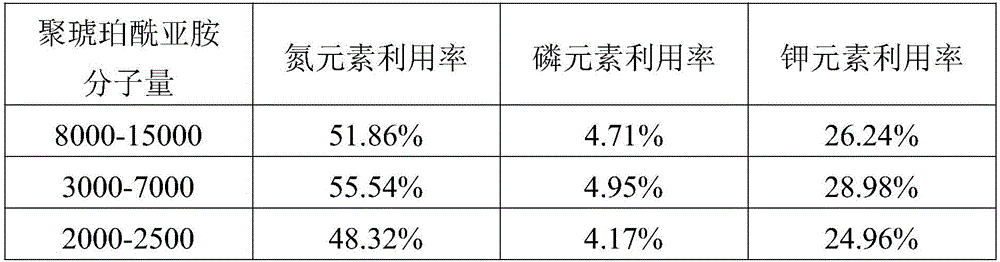

Combined fertilizer synergist containing polyglutamic acid, phosphate solubilizing bacteria and potassium bacteria and preparation method and application of combined fertilizer synergist

ActiveCN104276882AStrong ability to decompose inorganic phosphorusImprove bioavailabilityFertilizer mixturesPhosphate ionPhosphate solubilizing bacteria

The invention discloses a combined fertilizer synergist containing polyglutamic acid, phosphate solubilizing bacteria and potassium bacteria. The combined fertilizer synergist comprises the following components in proportion: phosphate solubilizing bacteria, potassium bacteria and polyglutamic acid at the mass ratio of (0.1-1) to (0.1-1) to (0.001-0.1). The invention also discloses a preparation method and application of the fertilizer synergist. The phosphate solubilizing bacteria disclosed by the invention are capable of effectively releasing phosphate anions (PO4<3+>) in soil or fertilizer; the potassium bacteria are capable of effectively releasing potassium ions (K<+>) in the soil or fertilizer; after being compounded with the phosphate solubilizing bacteria and the potassium bacteria, the polyglutamic acid not only can provide a good growth environment for survival of the phosphate solubilizing bacteria and the potassium bacteria, but also can fully chelate nutrient elements released by the phosphate solubilizing bacteria and the potassium bacteria; and due to the synergistic effect, the effect of solubilizing phosphate and potassium is relatively outstanding, therefore the combined fertilizer synergist can be cooperatively used together with fertilizers, the utilization rate of the fertilizer is increased, and the combined fertilizer synergist can also be directly fertilized as a bacterial manure.

Owner:轩凯生物科技(滁州)有限公司

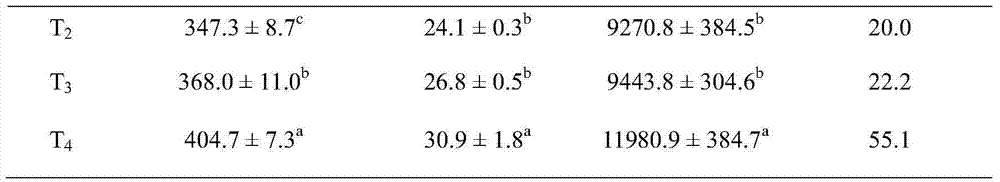

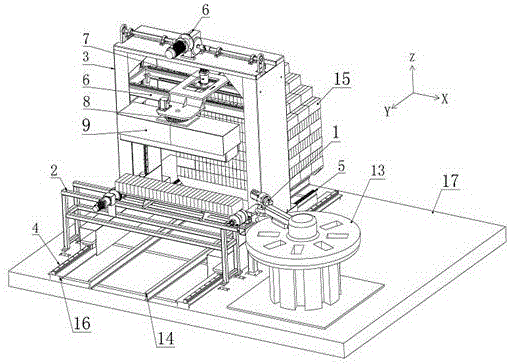

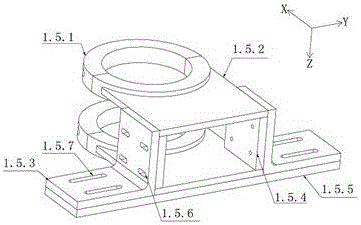

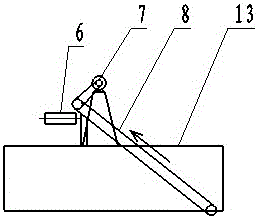

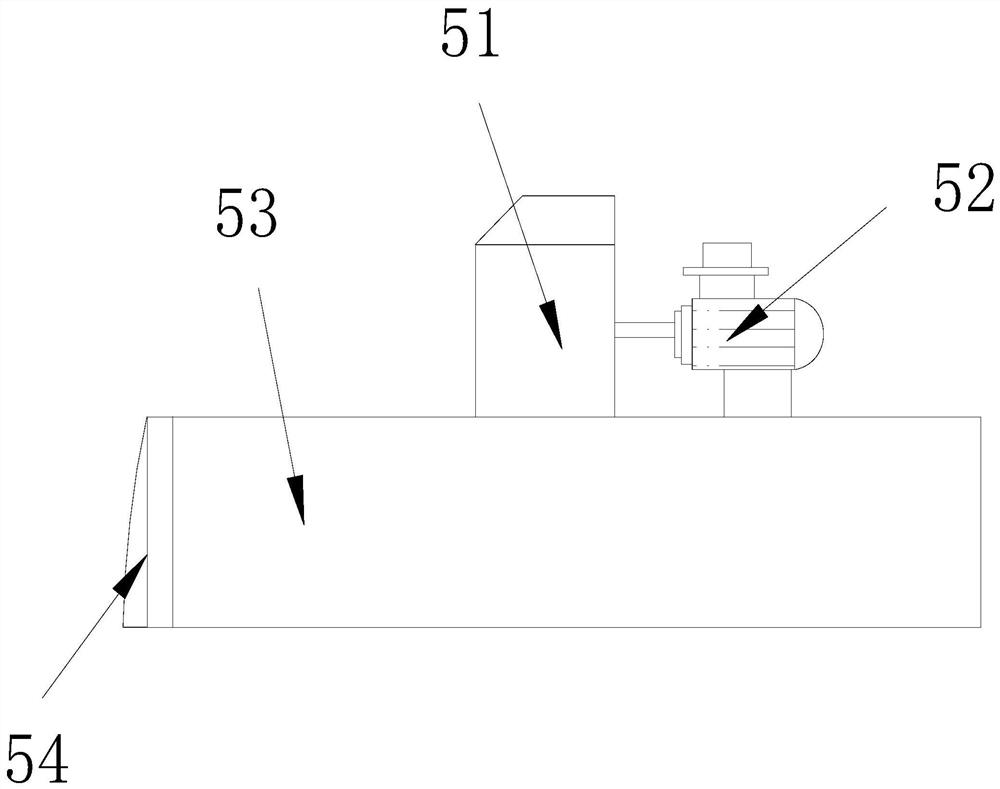

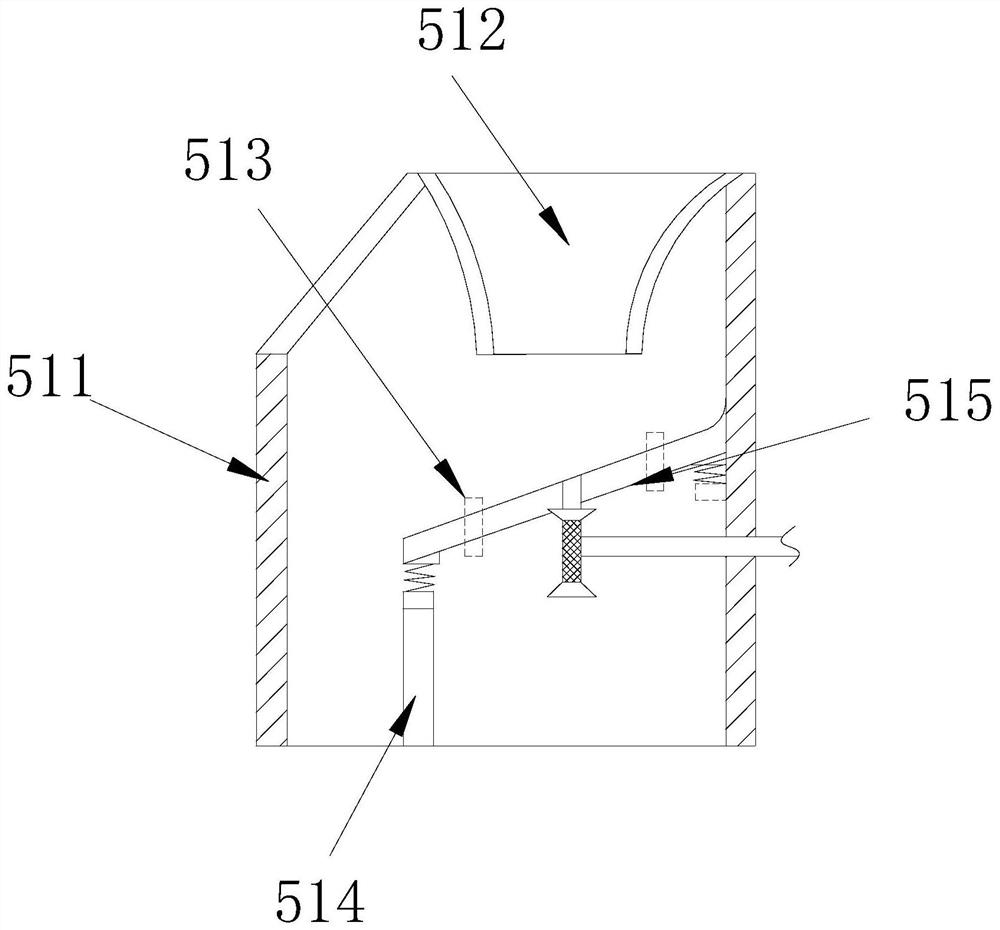

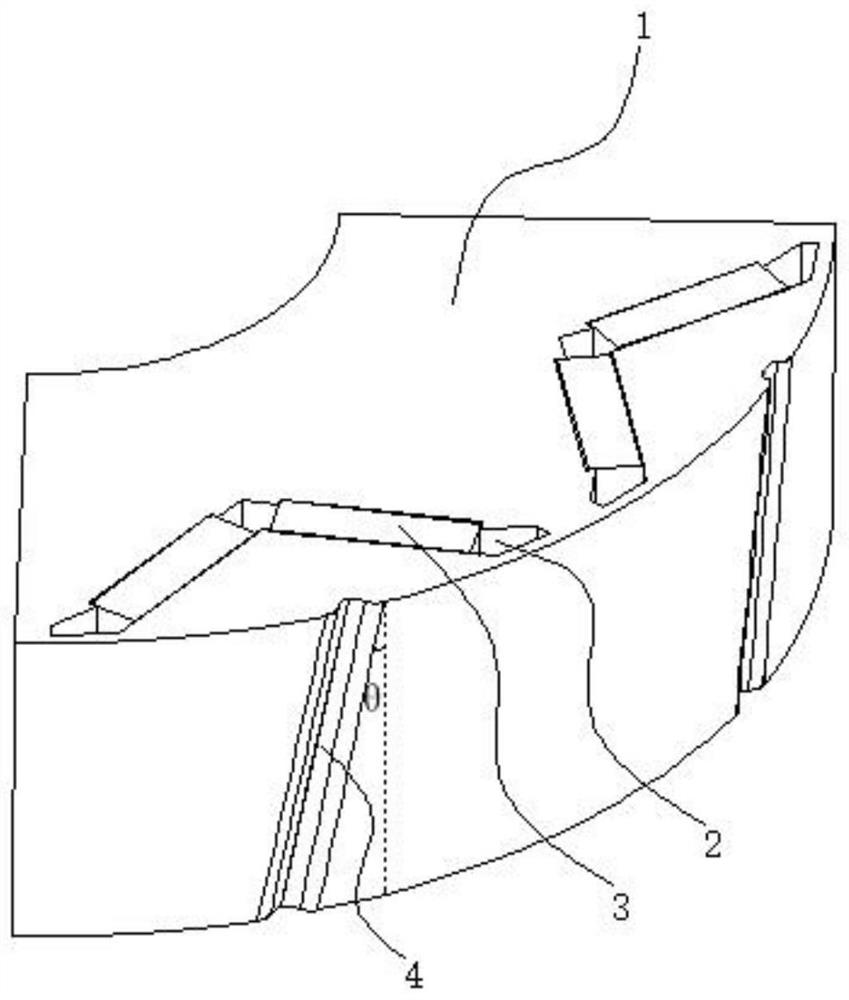

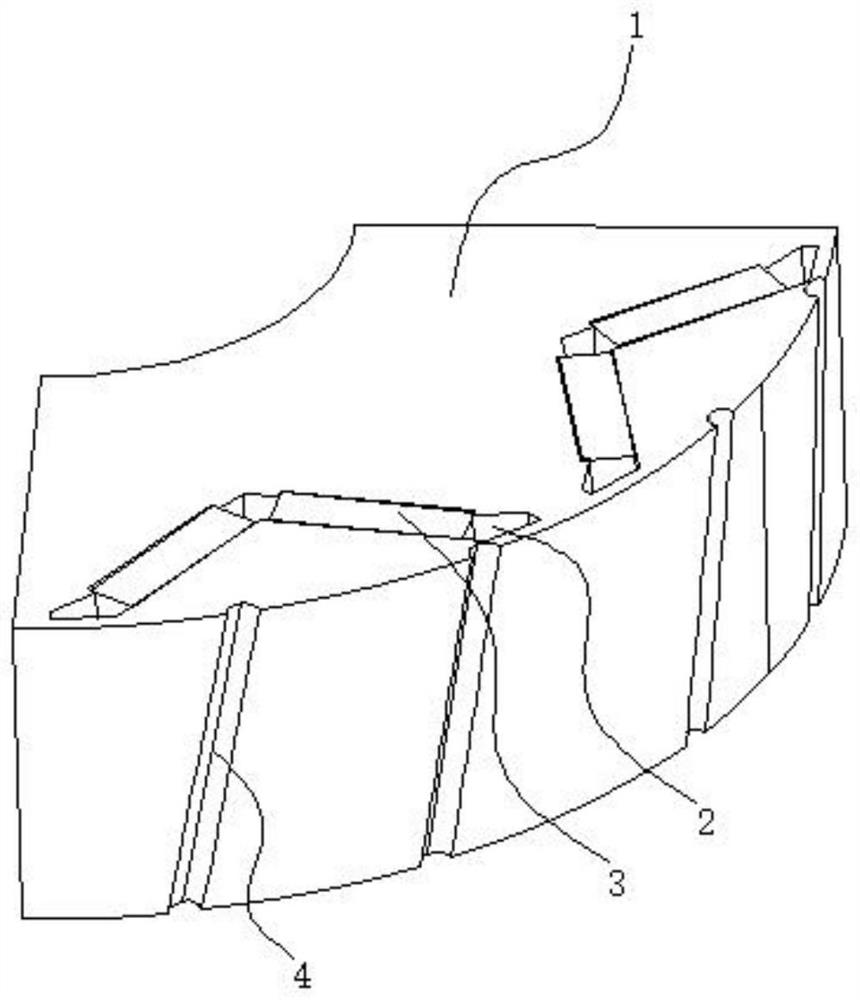

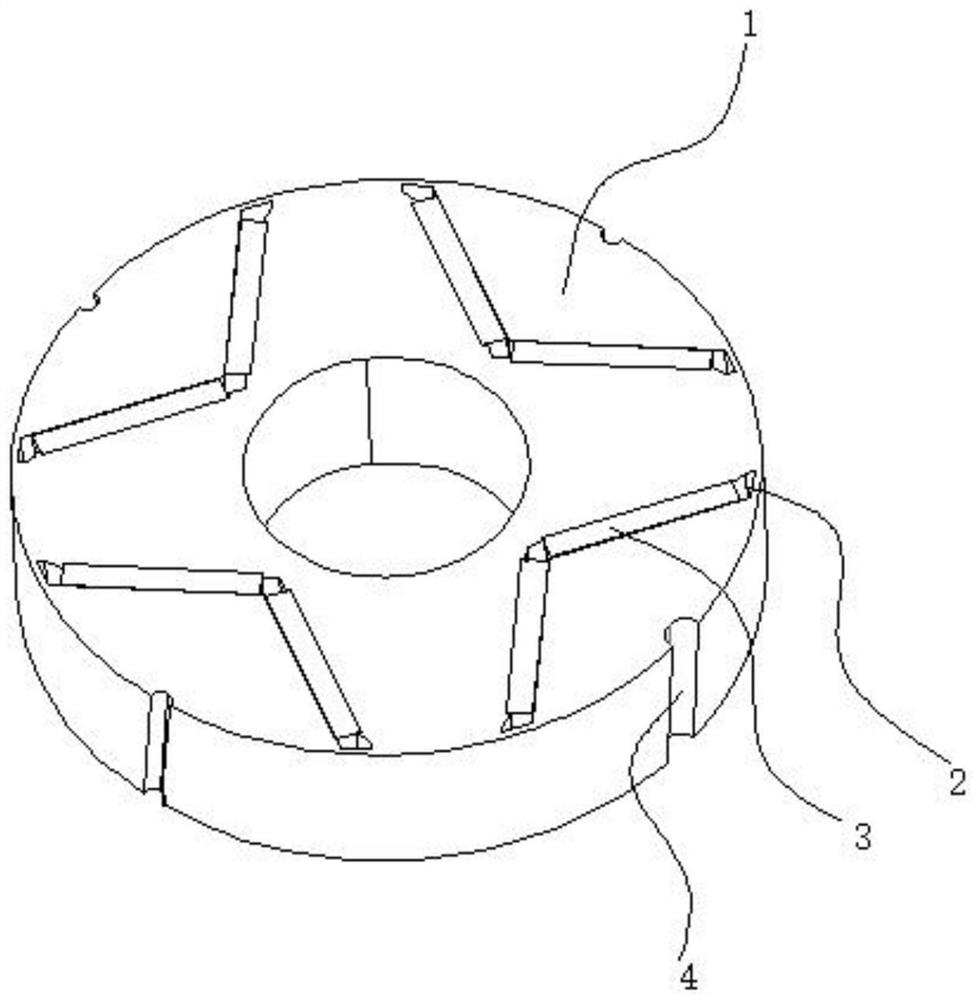

Adobe stacking machine and adobe stacking method

InactiveCN105836481AThe stacking method is criss-crossThe stacking method is criss-cross, without reducing the output of a single brick car.Stacking articlesDe-stacking articlesBrickControl system

The invention discloses an adobe stacking machine and an adobe stacking method. The adobe stacking machine comprises a small mechanical arm, a conveying line, a large mechanical arm with a movable portal frame as a frame and a control system. The portal frame serves as the frame of the large mechanical arm. The large mechanical arm comprises a lifting mechanism, an X axial movement mechanism, a rotating mechanism and a clamping mechanism. The lifting mechanism is located in the portal frame to slide vertically, and therefore the height of the whole equipment is controllable. The X axial movement mechanism slides left and right in the portal frame, and the requirement for stacking adobes clamped by the clamping mechanism to the two sides of a brick vehicle after the adobes are rotated is met to the maximum degree. The rotating mechanism and the clamping mechanism are arranged so that a rotating function can be increased for the large mechanical arm, the stacking direction of the adobes is changed by changing the rotating angle of the clamping mechanism, and therefore the adobes are sacked in a criss-cross manner, and the brick collapsing accident is avoided on the basis of not reducing the yield of a single brick vehicle.

Owner:CHANGDE GUIXIANG HYDRAULIC EQUIP CO LTD

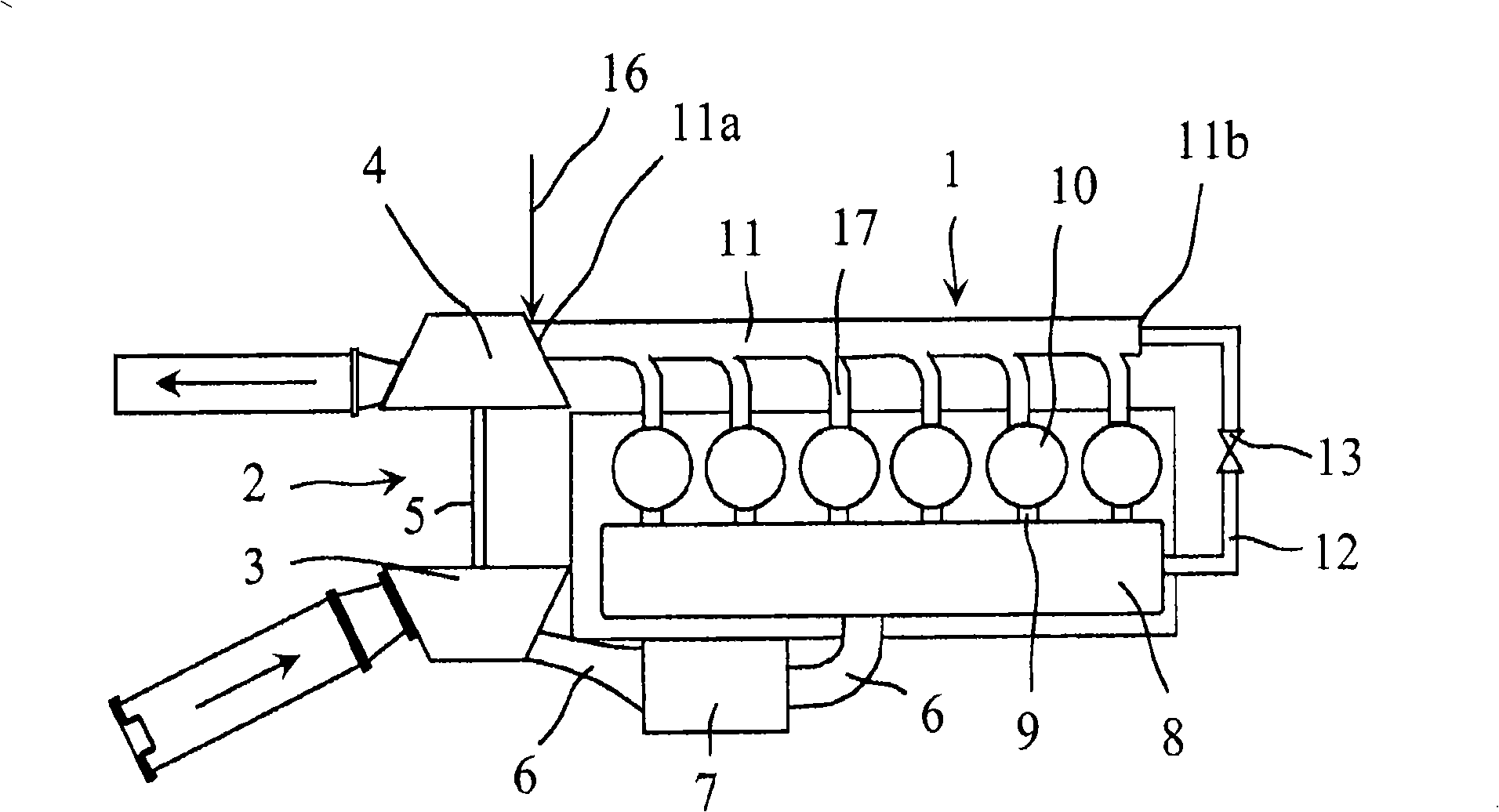

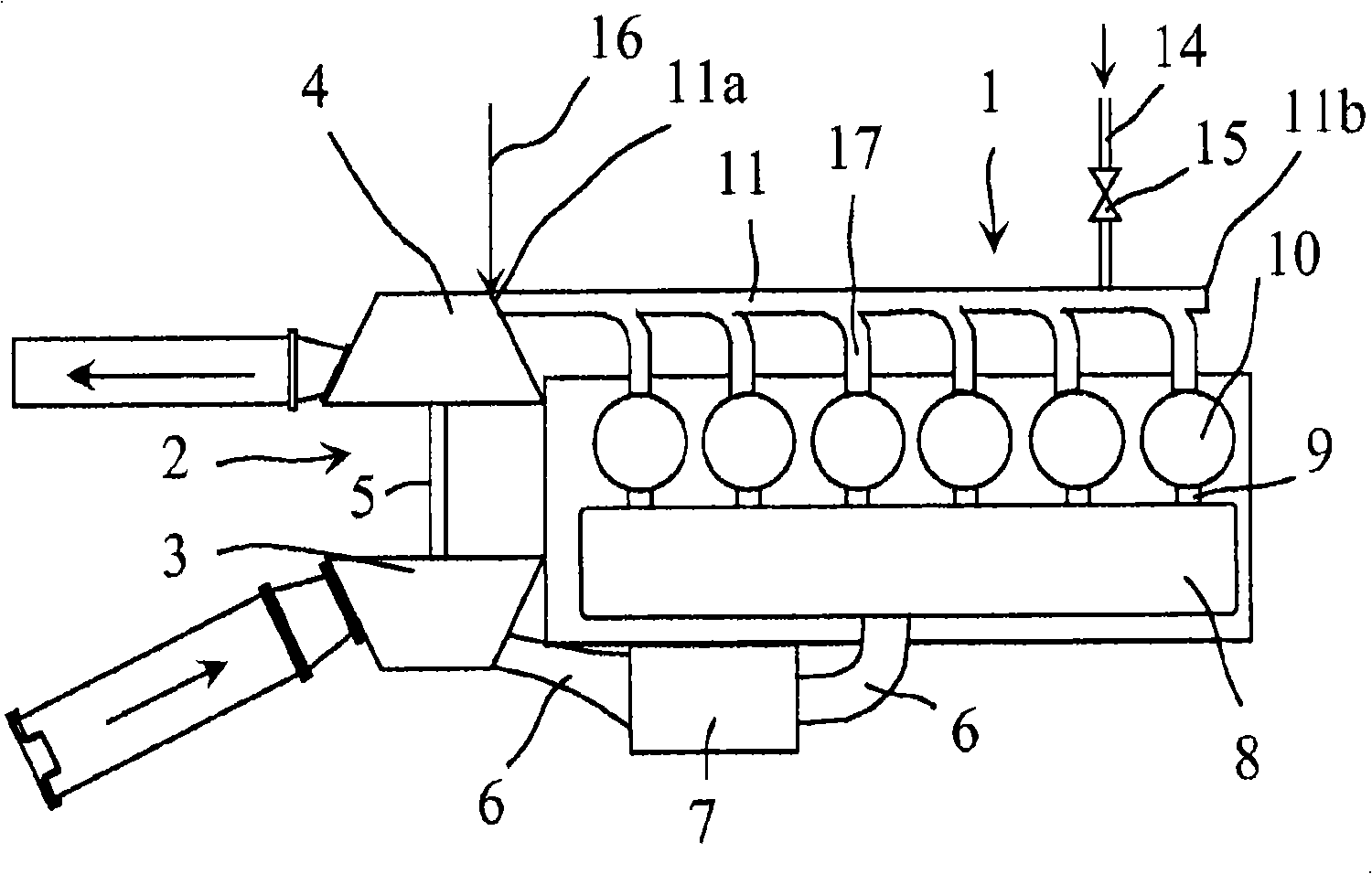

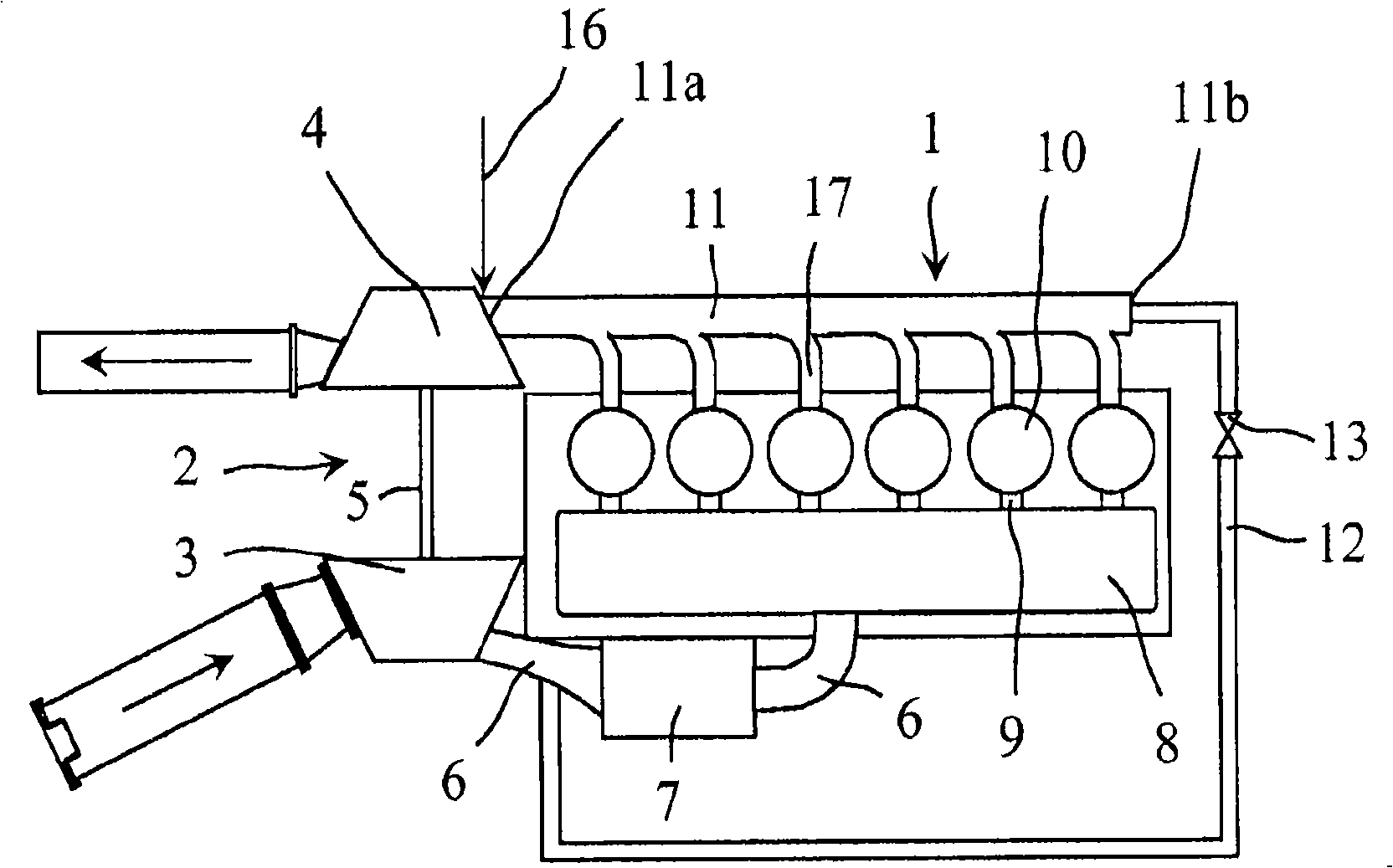

Turbocharger cleaning arrangement

ActiveCN101263279ANo reduction in outputInternal combustion piston enginesExhaust apparatusCombustionTurbocharger

An arrangement in connection with a piston engine (1) provided with a turbocompressor (2), which arrangement comprises a flow duct (6) for conveying combustion air pressurized by a compressor (3) to cylinders (10) of the piston engine (1), an exhaust gas duct (11) for conveying exhaust gas from the piston engine (1) to a turbine (4), and means (16) adapted in conjunction with the turbine (4) for feeding a cleansing agent to the turbine (4). There are feeding means (12; 14) arranged in connection with the exhaust gas duct (11) for introducing air and / or water into the exhaust gas duct (11) for cooling the exhaust gas.

Owner:WARTSILA FINLAND OY

Electric flocculation water treatment technology for retarding pole plate passivation

InactiveCN103613175ASlow down the rate of formationReduce outputWater/sewage treatmentFlocculationElectricity

The invention discloses an electric flocculation water treatment technology for retarding pole plate passivation, and belongs to the technical field of water treatment. The technology comprises the following steps: adding electrolyte sodium chloride to wastewater one time before electrolysis of each batch of wastewater in an intermittent electric flocculation process, so that the mean mass concentration of the sodium chloride inside an electrolytic cell is 40-200mg / L; outputting an intermittent electric flocculation voltage by a constant-pressure control power supply; and setting the voltage of each pair of electrodes to be 3-10V, the distance between the pole plates to be 5-15mm and the electrolytic time to be 30-90 minutes by adopting a direct current power supply. The problem of electrode surface passivation is improved and removed by in-situ generation of an acid substance on the electrode surface. The electric flocculation water treatment technology is free of feeding acid and base, and free of dismantling the electrodes to clean, and has the advantages of being simple in structure, and convenient to operate.

Owner:JIANGSU UNIV OF SCI & TECH

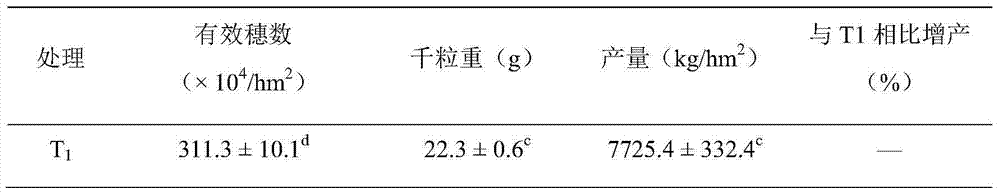

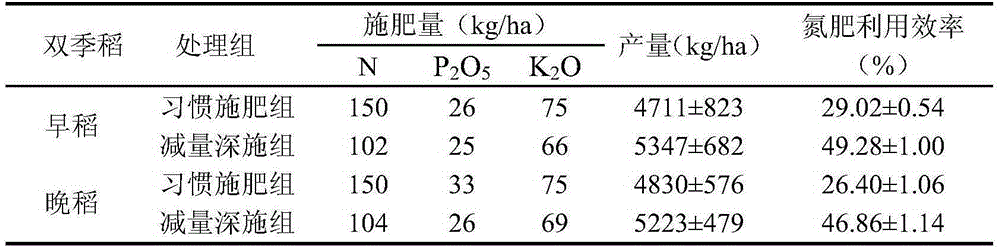

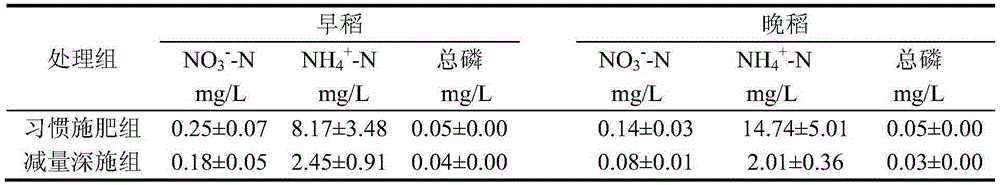

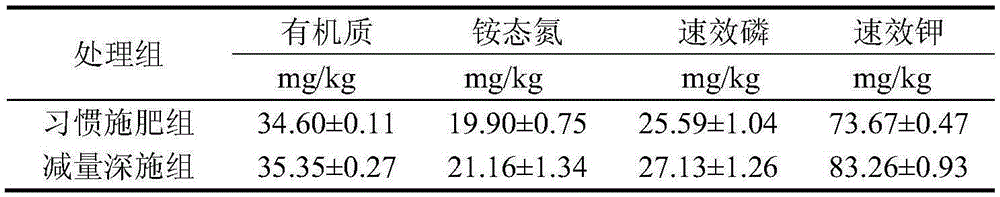

Amount-decreased chemical fertilizer deep application method based on reducing rice field nitrogen and phosphor non-point source pollution

InactiveCN105409418ANo reduction in outputReduce the amount of applicationFertilising methodsPhosphorOperability

The invention discloses an amount-decreased chemical fertilizer deep application method based on reducing rice field nitrogen and phosphor non-point source pollution. The method comprises the following steps: 1) determining the target yield of an amount-decreased chemical fertilizer deep application method of rice; 2) determining N, P and K nutrient quantity demands under the target yield; and 3) determining the fertilization application amount under the target yield; 4) applying chemical fertilizers: applying hole applied fertilizers and base fertilizers as fertilizers for early and late rice, wherein as for the hole applied fertilizers for early rice, the N fertilizer dosage is 25-30kg N / ha and the P fertilizer dosage is 25-30kg P2O5 / ha; as for the hole applied fertilizers for late rice, the N fertilizer dosage is 30kg N / ha; the base fertilizer dosages of early and later rice are equal to the fertilization application amounts under target yields of early and late rice minus the hole applied fertilizer dosages of early and late rice; the hole applied fertilizers of early and later rice are applied before rice transplanting in a spread manner, and the base fertilizers are prepared into fertilizer balls which are applied deep after rice transplanting. The method is capable of reducing the rice field nitrogen and phosphor non-point source pollution to a great extent and improving the fertilizer utilization efficiency, is high in operability in production, low in investment cost and relatively high in popularization and application value.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

Method for cultivating fungus in hanging manner on mango tree by taking trimmed mango branches and leaves as main raw material

ActiveCN102652486AUnique methodThe method is simpleHorticultureFertilizer mixturesAgaricWater quality

The invention relates to the new technical field of cultivation of edible fungi, in particular relates to a method for cultivating fungus in a hanging manner on a mango tree by taking trimmed mango branches and leaves as main raw materials. The method comprises the following concrete steps of: preparing a fungus growing culture medium and a fungus growing cultivation bag by taking the trimmed mango branches and leaves as main raw materials; producing the cultivation bags in two stages, namely March to April and August to September every year, and cutting the bags so that the fungis grow out in May to June and October to November respectively; during production and cultivation, the cultivation bags are hung on the mango tree according to a certain layout; and carrying out conventional fungus growth management until fungus is harvested. By applying the method disclosed by the invention, the mango tree is a foliage tree and is applicable to fungus cultivation, when the mango tree is used for cultivating fungus, obvious economic benefit can be produced remarkably, the original abandoned mango branches and leaves can be converted and utilized in large quantity, pollution to the air, soil, water quality and environment caused when the mango branches and leaves are burnt can be reduced, an industrial chain is prolonged, value of agricultural resource is increased in multilevel, additional value of an industry is increased, and rural income is increased.

Owner:昆明旭日丰华农业科技有限公司

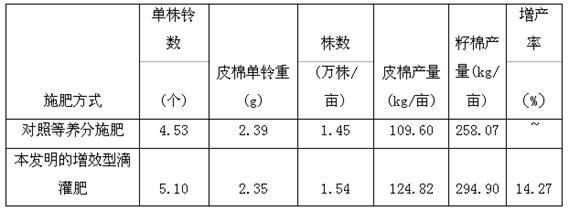

Synergistic drip irrigation fertilizer

ActiveCN102515965AImprove developmentIncrease resistanceFertilizer mixturesSoil scienceDrip irrigation

The invention provides synergistic drip irrigation fertilizer which contains the components in the following mass percentage: 15 percent of nitrogen fertilizer effective component, 6 percent of phosphorus fertilizer effective component, 9 percent of potassium fertilizer effective component, and 0.8 percent of synergistic agent. After the synergistic drip irrigation fertilizer is applied in crops in Xinjiang, all nutrients, such as nitrogen, phosphorus and potassium in the soil maintain higher effectiveness in all periods, the nitrogen fertilizer utilization rate is improved by 24 percent to 32 percent, the phosphorus fertilizer utilization rate is improved by 25 percent to 30 percent, and the potassium fertilizer utilization rate is improved by 30 percent to 35 percent. When the content of the applied nutrients is 80 percent of ordinary fertilizer, the yield of the crops is not reduced, and no element is lacked. When the fertilizer with equal nutrients is applied, after the synergistic drip irrigation fertilizer is applied, the yield of the crops in Xinjiang can be increased by 10 percent to 20 percent.

Owner:阿克苏市慧尔肥业有限公司

Method for cultivating funguses at bottoms of hawthorn trees by taking hawthorn tree branches and leaves as major raw materials

InactiveCN104350941ASimple processEasy to implementCultivating equipmentsMushroom cultivationAgaricOrganic fertilizer

A method for cultivating funguses at the bottoms of hawthorn trees by taking hawthorn tree branches and leaves as major raw materials particularly comprises the steps of selecting woodland of the hawthorn trees which are about 1.5m in height and about 1-1.2m in crown width as a cultivating site, preparing a fungus emerging culture medium by taking the trimmed hawthorn tree branches and leaves as the major raw materials, vertically placing fungus emerging bags in 3-4 rows around each hawthorn tree at the bottom of each hawthorn tree after culture of the fungus emerging bags, and carrying out management as usual till the funguses emerge. The site for implementing the method, the woodland of the hawthorn trees, is idle all the time in a hawthorn producing area and wide in area, and expenses such as land rent are not required to be paid during use. At the same time, various weeds and sundries at the bottoms of the hawthorn trees are removed completely by implementing the method, the remaining culture medium after the funguses are harvested can be directly taken as organic fertilizer for the land, and effectively improve soil, and comprehensive cyclic utilization is achieved.

Owner:广西靖西市壮佳农业发展有限责任公司

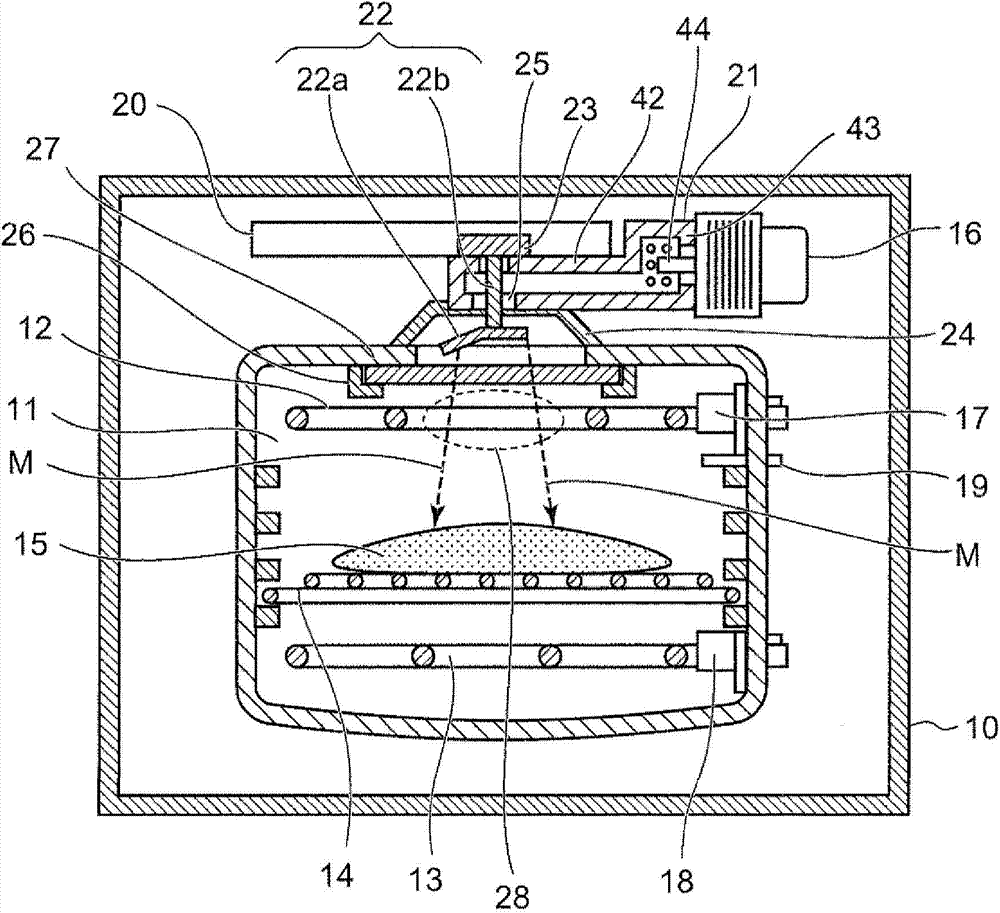

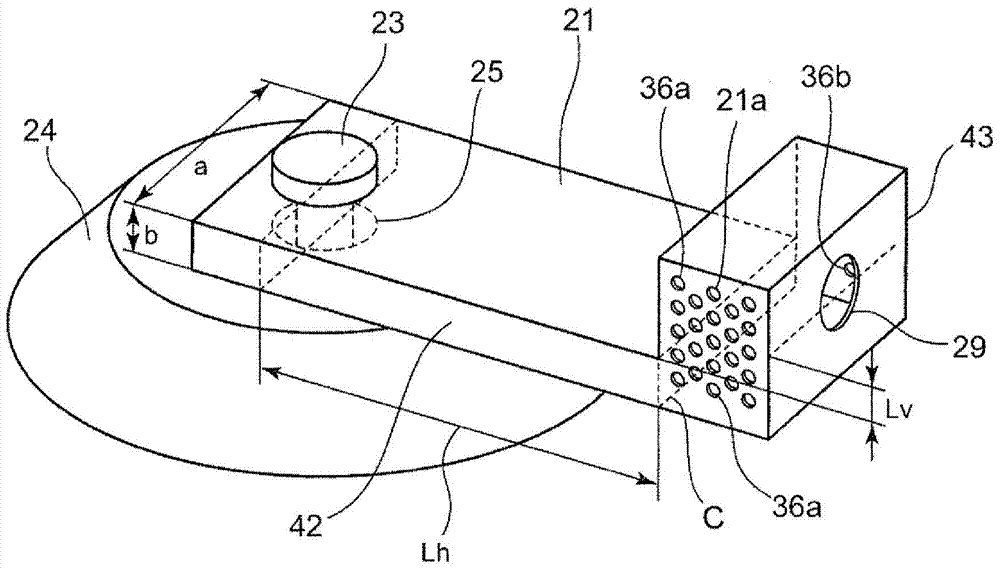

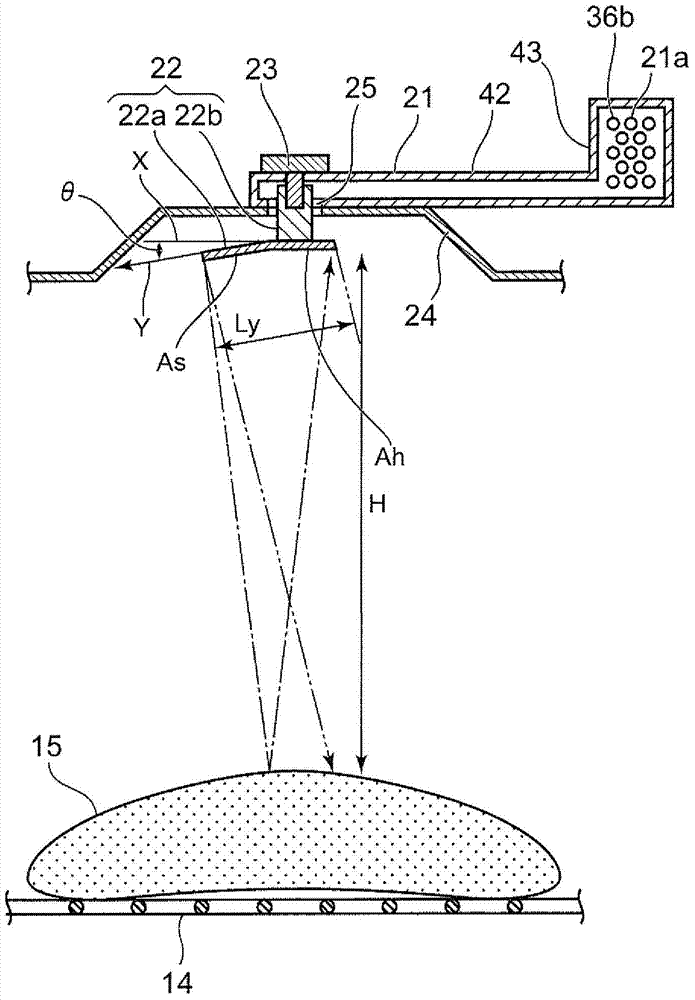

Microwave heating device

ActiveCN103718645ASituation to reduce reflected wavesSuppression of reflected wave componentsMicrowave heatingCouplingWaveguide

This microwave heating device comprises a power feed unit (22) that emits microwaves and has the following: a vertical shaft element (22b) that is provided in a vertical direction by penetrating a coupling hole (25) formed at an area where a power feed chamber (24) and a waveguide (21) connect; and a plate element (22a) that connects to the vertical shaft element and has an emission surface for emitting microwaves to the heating chamber. At least a portion of the microwave emission surface of the plate element is disposed so as to be oblique at a prescribed angle with respect to the horizontal direction.

Owner:PANASONIC CORP

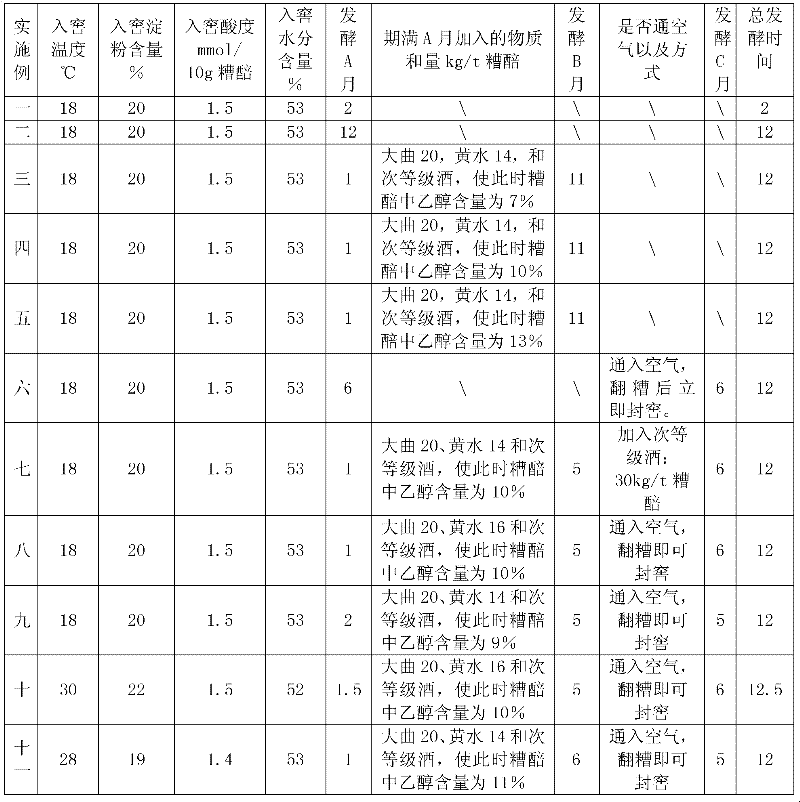

Solid fermentation method of fragrant white spirit

ActiveCN102344867AQuality improvementTake advantage ofAlcoholic beverage preparationBiotechnologyAlcohol

The invention discloses a solid fermentation method of fragrant white spirit, belonging to the technical field of brewing. The invention needs to solve the technical problem of providing a fermentation method for further improving the quality of white spirit on the basis of not reducing the output. The technical scheme of the fermentation method comprises the following steps of: loading yeast powder and fermented grains into a pit, fermenting the starter powder and the fermented grains in a sealed way, and adding yeast for making hard white spirit, yellow water and low-grade spirit into the fermented grains while fermenting for 1-2 h so that the content of alcohol in the fermented grains is 9-11% by weight; opening the pit, and turning the grains and fermenting the grains in a sealed way while fermenting for 5-6 months after the yeast for making hard white spirit, the yellow water and the low-grade spirit are added into the fermented grains. In the method provided by the invention, byadopting the measures of adding the yeast for making hard white spirit, the yellow water and the low-grade spirit into the fermented grains at specific time, adjusting the concentration of alcohol, introducing air into the fermented grains and the like, te quality of the fragrant white spirit is further improved on the basis of not reducing the output, and good benefit can be obtained by applyingthe method to the fermentation of fragrant white spirit.

Owner:LUZHOU PINCHUANG TECH CO LTD

Synergistic bioorganic drip irrigation fertilizer

InactiveCN102531783AReduce outputLess prone to deficiency symptomsFertilizer mixturesAgricultural scienceAgricultural engineering

The invention provides a synergistic bioorganic drip irrigation fertilizer, which comprises the following components in percentage by mass: 12 percent of a nitrogen fertilizer active ingredient, 20 percent of a phosphorus fertilizer active ingredient, 8 percent of a potassium fertilizer active ingredient and 0.1 percent of a synergistic agent. After the synergistic bioorganic drip irrigation fertilizer provided by the invention is applied to crops in Xinjiang, the nitrogen, phosphorus and potassium nutrients in soil can keep high effectiveness at each stage, the utilization ratio of a nitrogen fertilizer is increased by 24-32 percent, the utilization ratio of a potassium fertilizer is increased by 25-30 percent, and the utilization ratio of the potassium fertilizer is increased by 30-35 percent. Due to the adoption of the synergistic bioorganic drip irrigation fertilizer provided by the invention, organic matters and animal residues can be well decomposed, and nutrients are released; and soil is activated, and nutrients are supplied to plants. When the content of applied nutrients is 80 percent of the content of an ordinary fertilizer, the crop yield is not reduced, and a nutritional deficiency symptom is prevented. Under the condition that fertilizers of equal nutrients are applied, the yield of the crops in Xinjiang can be increased by 10-20 percent by applying the synergistic bioorganic drip irrigation fertilizer provided by the invention.

Owner:XINJIANG HUIER AGRI GRP CO LTD

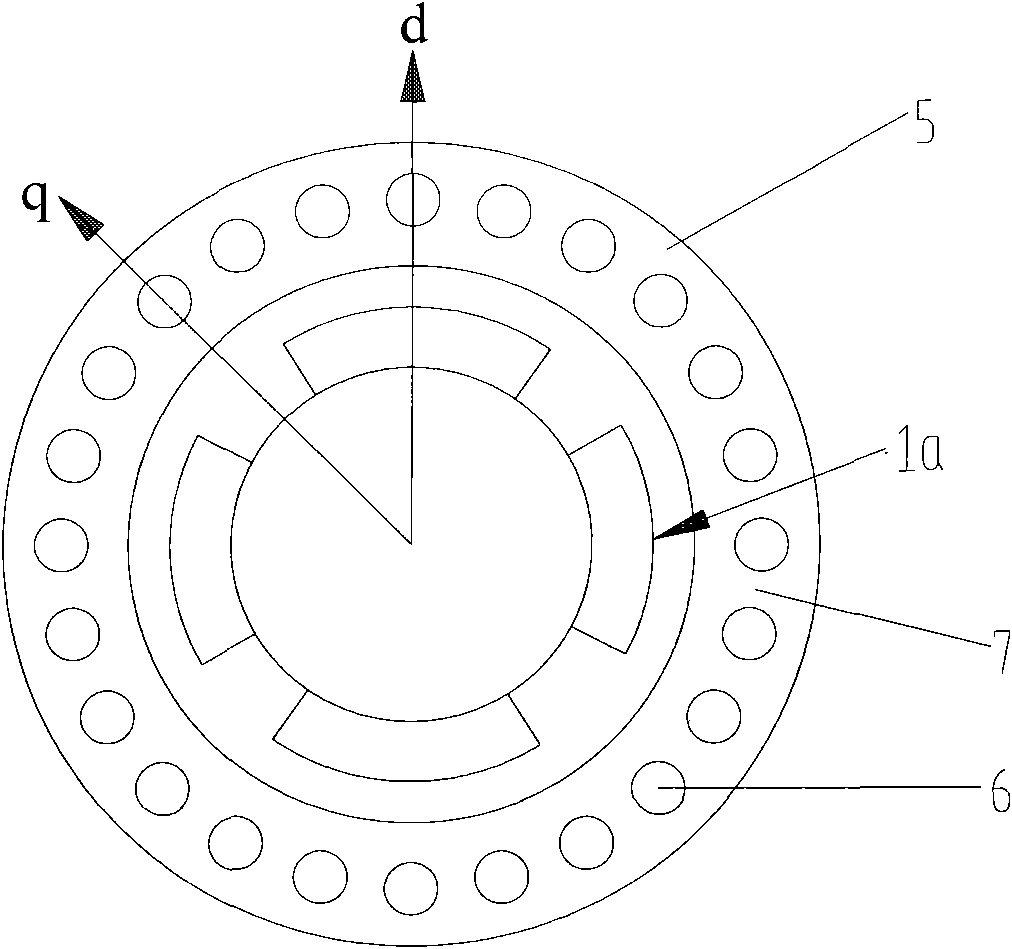

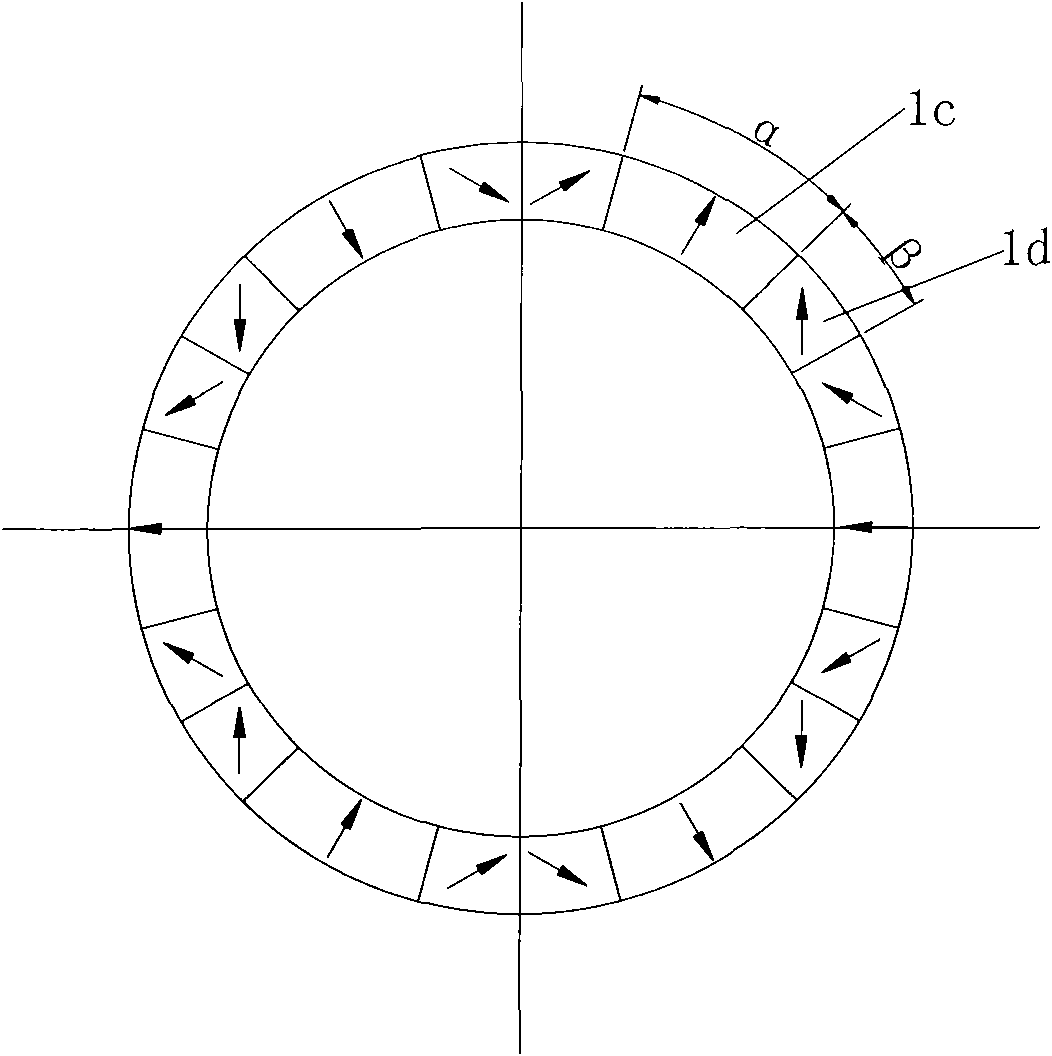

High-precision low-fluctuation permanent magnetic brushless servomotor for solar tracking system

InactiveCN101572468AHigh precisionImprove overload capacityMagnetic circuit rotating partsLight radiation electric generatorLow noiseMagnetic poles

The invention relates to a high-precision low-fluctuation permanent magnetic brushless servomotor for a solar tracking system, which comprises a machine shell as well as a stator and a rotor in the machine shell, wherein the stator comprises a stator core fixed on the inner wall of the machine shell and a stator winding; the rotor comprises a main shaft and a rotor core; the outer circumference of the rotor core is sleeved with an annular magnetic pole consisting of radial magnetized magnetic steels which are evenly arranged along the circumferential direction and adjacent oblique angled magnetized magnetic steels; one radial magnetized magnetic steel and two adjacent oblique angled magnetized magnetic steels in the annular magnetic pole form a rotor magnetic pole; the radial magnetized magnetic steels are main magnetic poles; and the two adjacent oblique angled magnetized magnetic steels on both sides are auxiliary magnetic poles. Radial and oblique angled mixed anisotropic magnetized magnetic poles in the annular magnetic pole of the rotor ensure that the motor can also remarkably improve air gap flux density waveform of the motor even if the even air gap is adopted, obtain a sinewave magnetic field, does not reduce power output, can also reduce moment fluctuation, and improve the precision of the solar tracking system. The motor can perform steady operation with high efficiency, low fluctuation, low noise, quick response and high precision.

Owner:苏州工业园区美能新能源有限公司 +1

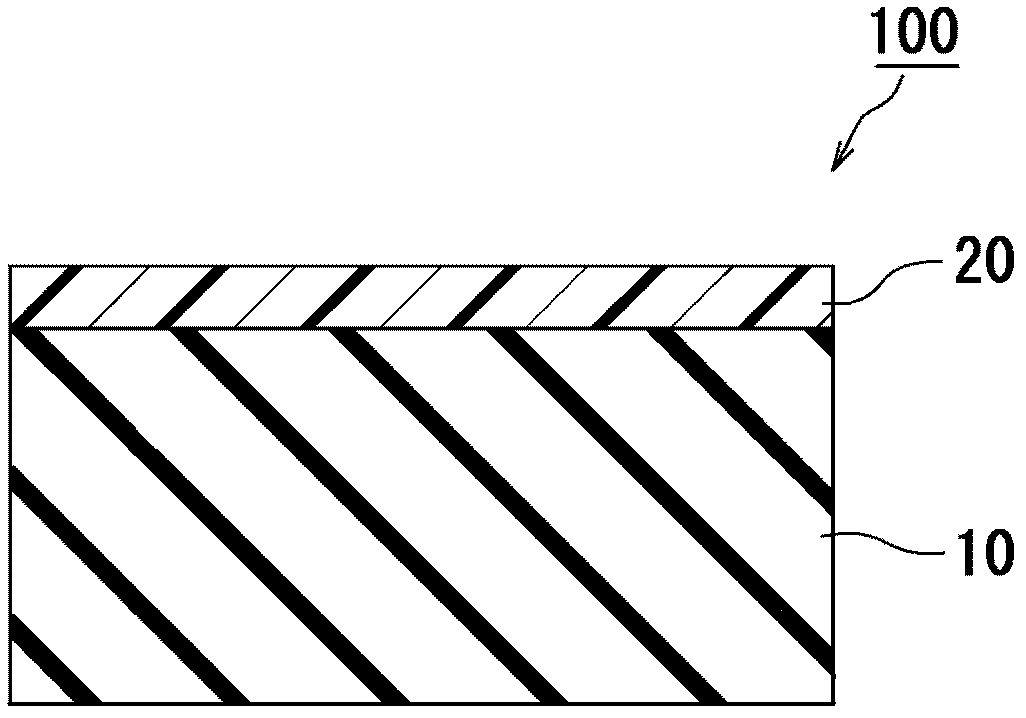

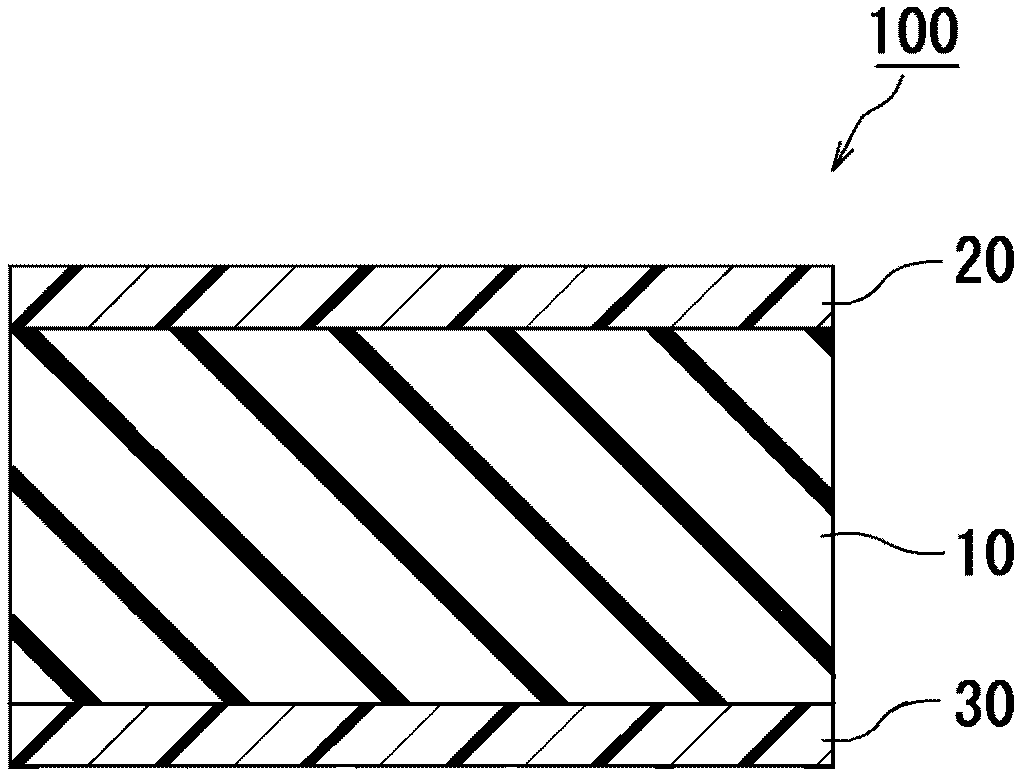

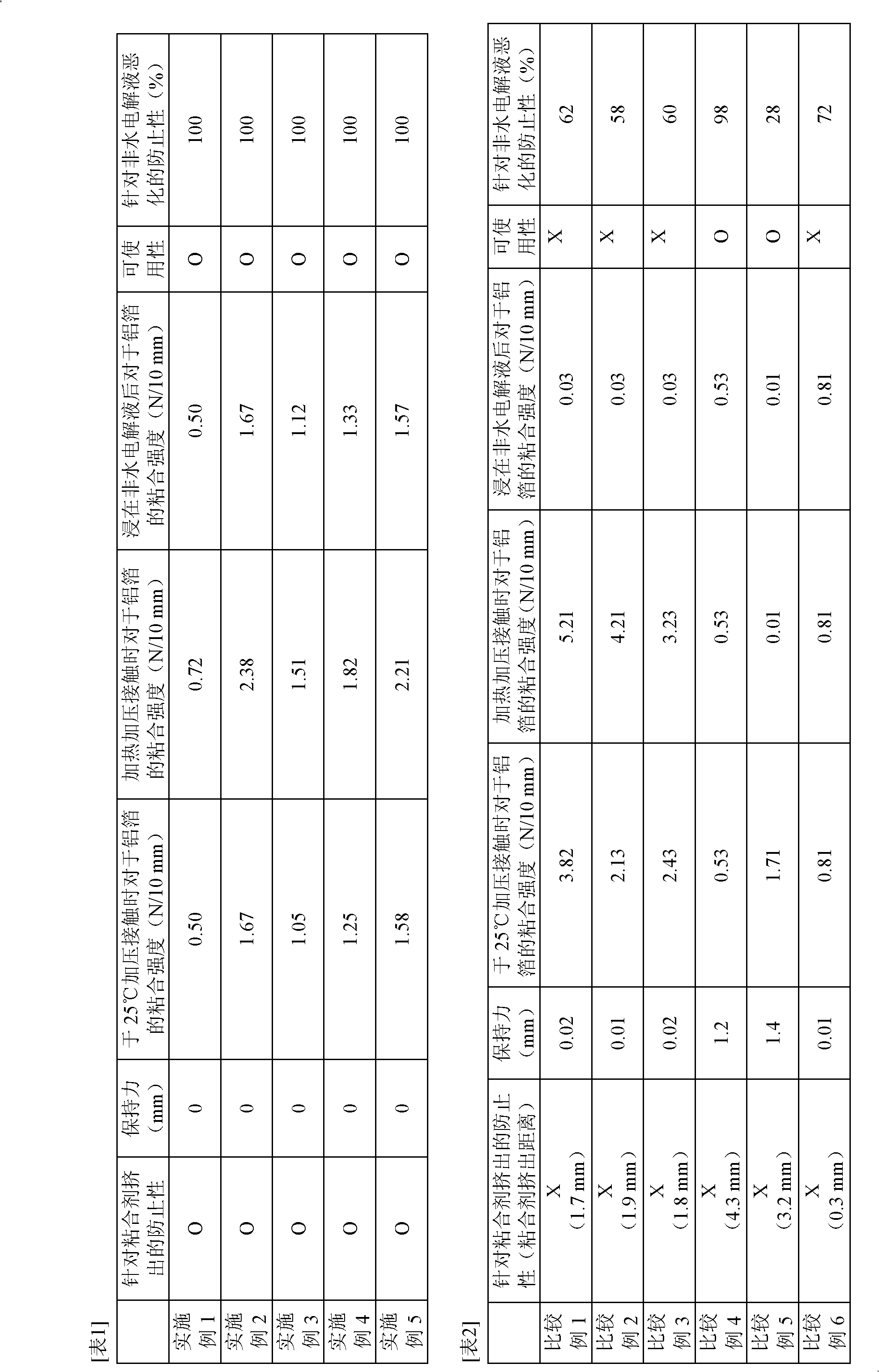

Laminate for nonaqueous battery

InactiveCN102618184AHas adhesive strengthInhibit deteriorationFinal product manufactureSecondary cellsPolyolefinCohesive strength

Provided is a laminate for a nonaqueous battery having moderate adhesion to be used in a nonaqueous battery in which a nonaqueous electrolytic solution is sealed, the laminate for a nonaqueous battery being capable of improving the suitability of electrodes to be packed into a battery case without causing a reduction in battery output, being capable of preventing a short circuit between the electrodes caused by the penetration of a burr or the like present on an electrode plate through a separator, being capable of suppressing the reduction of the adhesion in the nonaqueous electrolytic solution, being capable of suppressing the deterioration of the nonaqueous electrolytic solution, and having such a cohesive strength that when the laminate is used in the form of a tape, a pressure-sensitive adhesive layer does not squeeze out of a base material layer. The laminate for a nonaqueous battery is formed of at least two layers, including: a base material layer (A); and a pressure-sensitive adhesive layer (B) in the stated order, in which: the base material layer (A) contains a polyolefin-based thermoplastic resin; and the pressure-sensitive adhesive layer (B) contains Alpha--olefin-based thermoplastic resin.

Owner:NITTO DENKO CORP

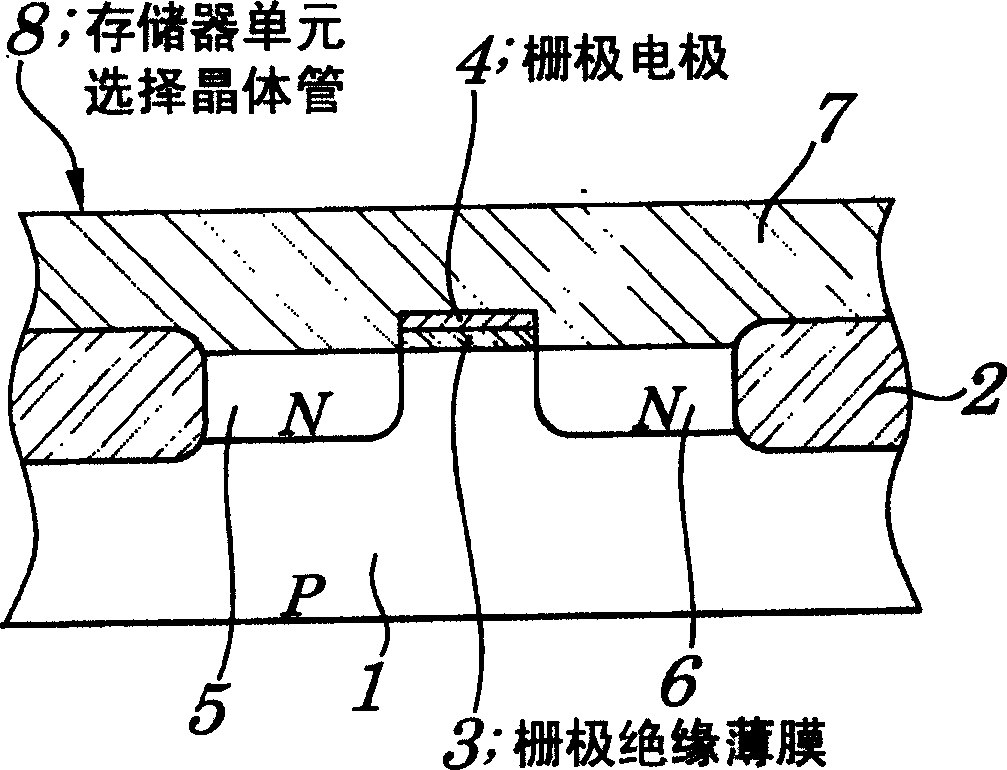

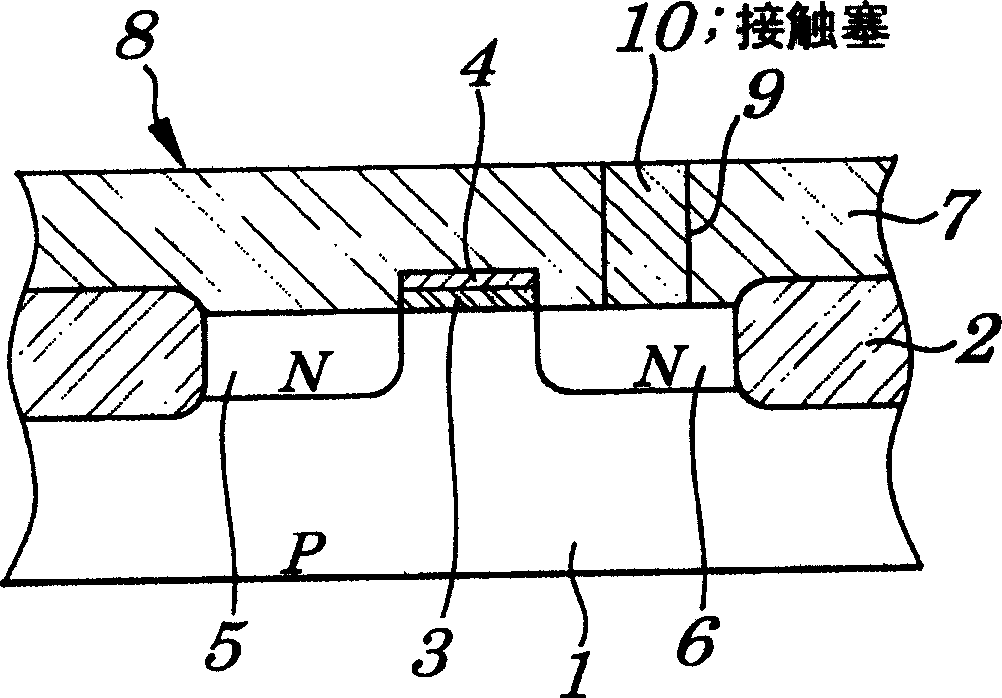

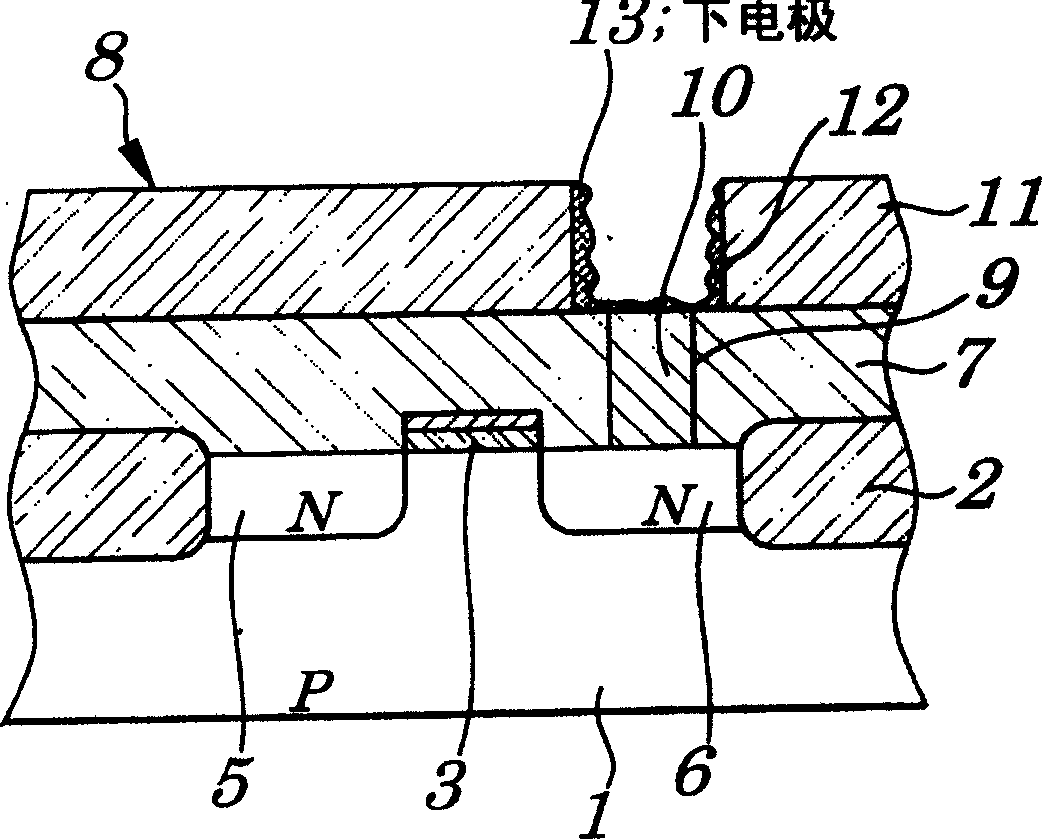

Method for manufacturing semiconductor device

InactiveCN1471143AGood step coverageImprove film qualityTransistorSolid-state devicesCapacitanceDual stage

There is provided a method for manufacturing a semiconductor device including a capacitor having a lower electrode, an upper electrode and a capacitive insulating film between the lower electrode and the upper electrode on a semiconductor substrate, wherein the capacitive insulating film is formed on the lower electrode over the semiconductor substrate using a chemical vapor deposition method, the method including: a lower electrode forming step of forming the lower electrode on the semiconductor, a dual-stage deposition step including a first stage for introducing a material gas containing a specified metal into a reactor in which the semiconductor substrate is placed and a second stage for subsequently introducing an oxidizing gas into the reactor, and wherein a metal oxide film as an oxide of the specified metal is formed on the lower electrode over the semiconductor substrate, by repeating the dual-stage deposition step two or more times, thereby forming the capacitive insulating film; and an upper electrode forming step of forming the upper electrode on the capacitive insulating film. Thus, it is possible to obtain the capacitive insulating film having good step coverage and a good film quality, without reducing throughput.

Owner:PS4 LUXCO SARL

Method for cultivating edible fungus in the tree bottom by taking trimmed lychee leaves as main raw materials

InactiveCN106165613ASimple processEasy to operateCultivating equipmentsMushroom cultivationEdible mushroomHorticulture

The invention discloses a method for cultivating edible fungus in the tree bottom by taking trimmed lychee leaves as the main raw materials, belonging to the technical field of domestic fungus cultivation. The method includes planting season arrangement and edible fungus cultivation woodland selection, medium preparation, edible fungus cultivation bag preparation, cultivation, and edible fungus growing management. According to the invention, the stereo comprehensive utilization of the lichee woodland is realized, the benefit is improved, and the aim of increase income is achieved.

Owner:蔡凤文

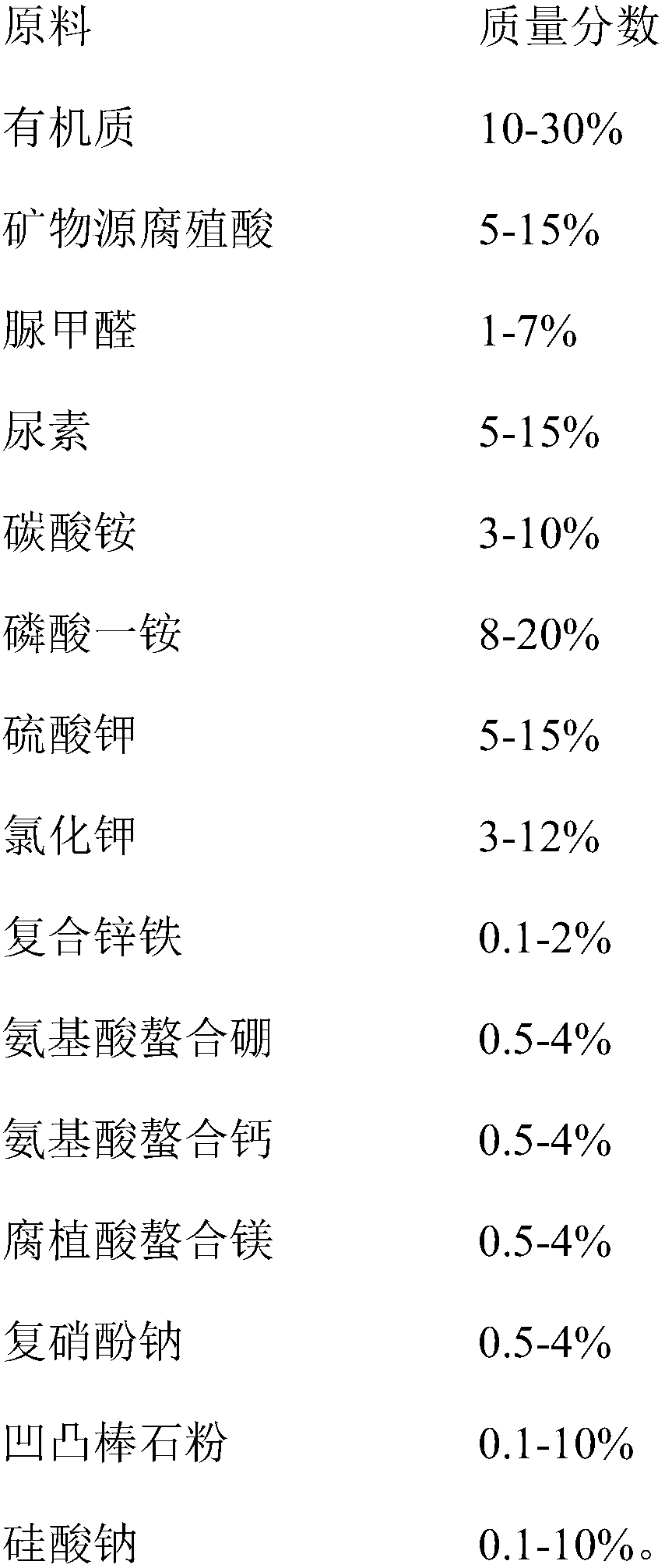

Organic and inorganic compound fertilizer for cotton field and preparation method thereof

PendingCN109593009AWide range of sourcesEasy to killAlkali orthophosphate fertiliserExcrement fertilisersPhosphateCarbonization

The invention discloses organic and inorganic compound fertilizer for a cotton field and a preparation method thereof. The organic and inorganic compound fertilizer for the cotton field is prepared from organic matters, mineral-sourced humic acid, urea formaldehyde, urea, ammonium carbonate, monoammonium phosphate, potassium sulfate, potassium chloride, compound zinc and iron, amino acid chelatedboron, amino acid chelated calcium, amino acid chelated magnesium, compound sodium nitrophenolate, attapulgite powder and sodium silicate according to a certain ratio. The organic and inorganic compound fertilizer disclosed by the invention can meet the requirements of the growth of cotton on nitrogen, phosphorus and potassium, but also can be used for supplementing medium and trace elements including calcium, magnesium, boron, iron, zinc and the like; the organic and inorganic compound fertilizer also contains the organic matters and the humic acid and is more suitable for being applied to soil with relatively low organic matter content; secondly, the organic matters have a wide source and are easy to obtain; anaerobic carbonization treatment before processing also can be used for killingharmful microorganisms very well; after application, other negative influences are not generated; and condensed water and refluxing liquid in a processing process can be used for dissolving other substances and processing wastewater is not discharged to pollute the environment.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

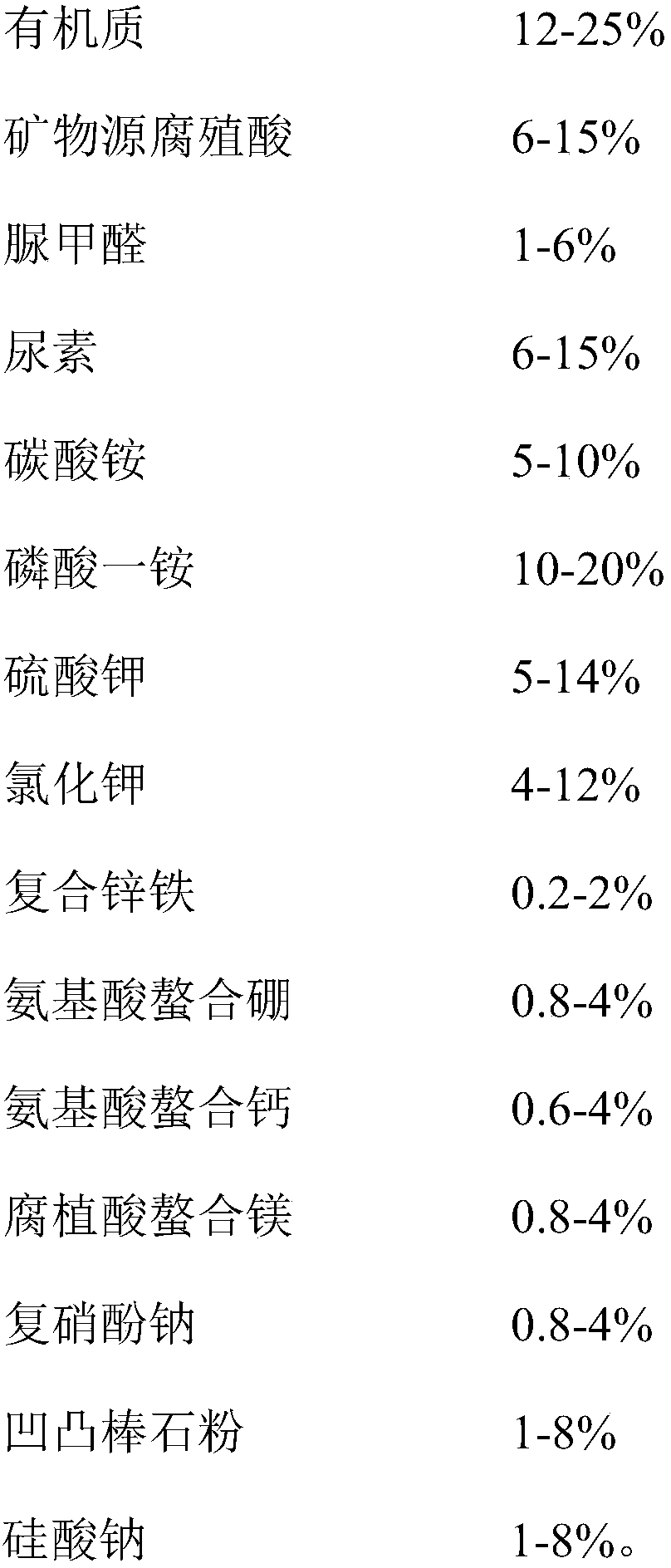

Sheet metal bending machine

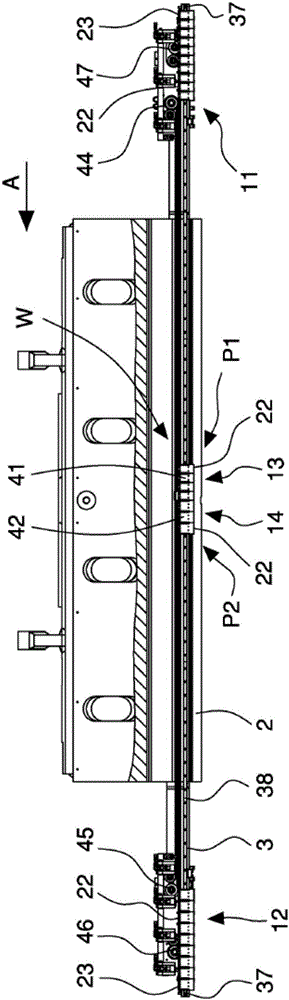

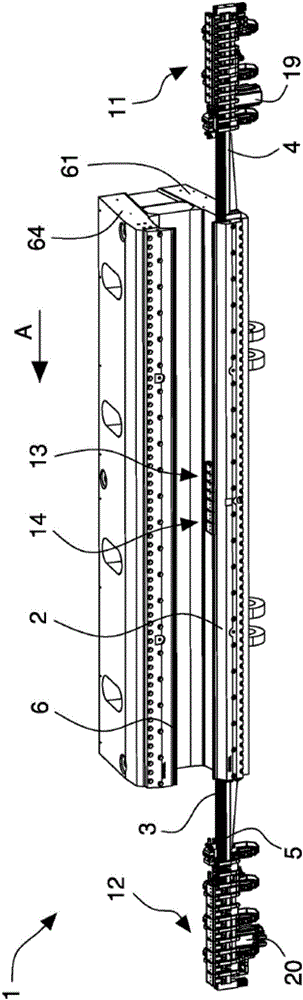

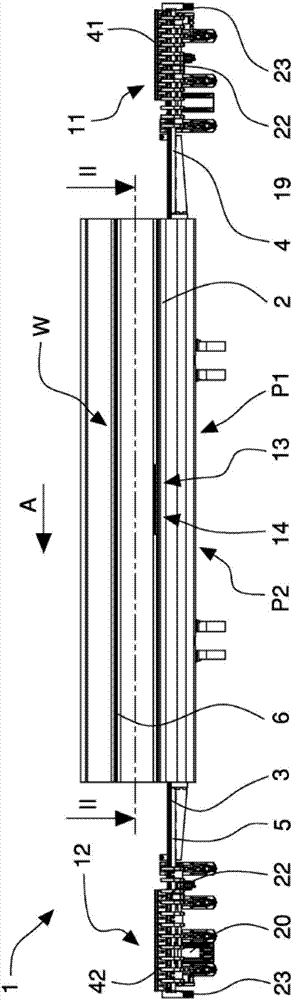

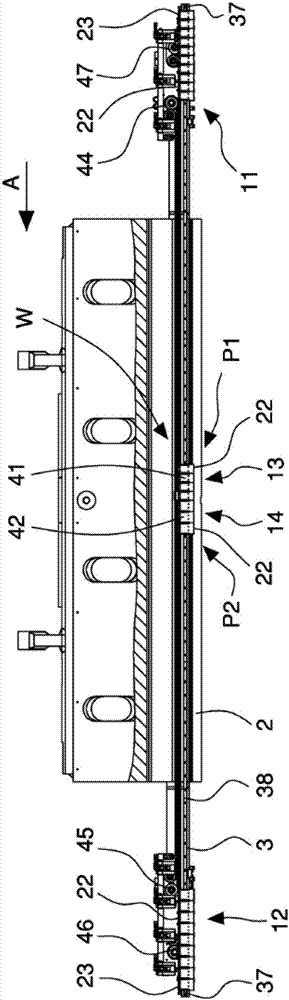

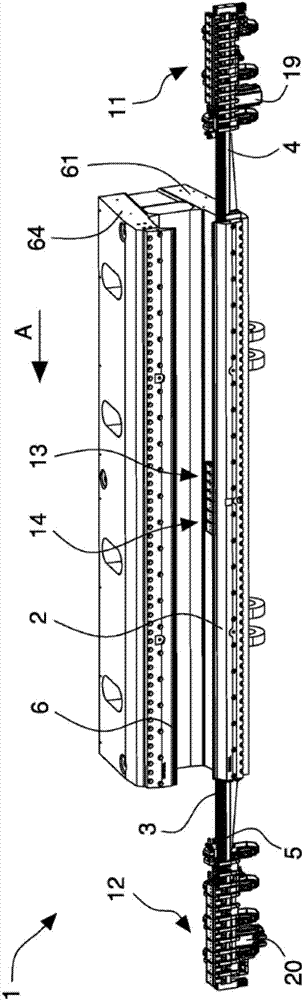

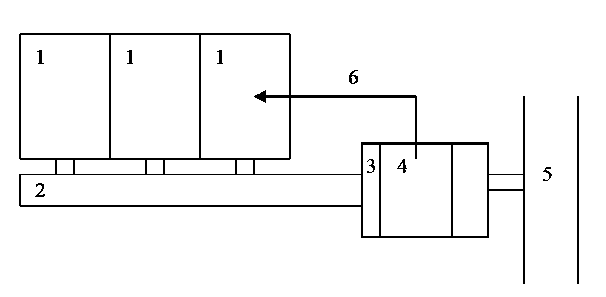

A sheet metal bending machine comprises main bending tool means (2; 6) that extends along a longitudinal direction (A) and is movable so as to bend a workpiece (50), guide means (3) associated and parallel to the main bending tool means (2; 6), extending through a working zone (W) of the bending machine (1) and sideways protruding from the latter at least with a first end portion (4), and shuttle means (21, 22, 23) slidably mounted on said guide means (3) and supporting at least one auxiliary tool (41, 42) to be associated with the main bending tool means (2; 6) in order to execute partial bends on the workpiece (50); the shuttle means (21, 22, 23) are movable along the longitudinal direction (A) between a first active position (P1), in which the shuttle means (21, 22, 23) is inside the working zone (W) and the auxiliary tool (41, 42) is mounted on the main bending tool means (2; 6), and a first inactive position (R1), in which the shuttle means (21, 22, 23) is outside the working zone (W) and positioned at the first end portion (4) of guide means (3); the shuttle means comprises a first set (11) of shuttles (21, 22, 23), each shuttle (21, 22, 23) carrying a respective auxiliary tool (41, 42), said shuttles (21, 22, 23) being mutually connectable to form a first shuttle convoy (13) having a selectable number of shuttles (21, 22, 23); the first shuttle convoy (13) is movable between said first inactive position (R1) and said first active position (P1) in order to mount a defined composition of auxiliary tools (41, 42) on the main bending tool means (2; 6).

Owner:SALVAGNINI ITAL

Method for cultivating Chinese goldthread under peach trees

InactiveCN106069030AIncrease incomeSimple processPlant cultivationCultivating equipmentsForest managementPistacia

The invention discloses a method for cultivating Chinese goldthread under peach trees, and belongs to the technical field of planting. The method particularly comprises the steps of land selection and preparation, seeding and transplanting, forest management, pest control and the like. By means of implementation of the method for cultivating the Chinese goldthread under the peach trees, an industrial chain is prolonged, multistage value increasing of agricultural resources is achieved, the additional value of the industry is increased, and the income of farmers is increased. Meanwhile, the land output can be increased conveniently; by means of the cultivation mode, on the premise that the farmers do not increase investment, yield increasing of the peach trees is promoted through tillage and weeding and topdressing and ridging in the process of planting the Chinese goldthread under a forest, and the yield of the peach trees is not decreased, a three-dimensional agricultural production double harvest is achieved.

Owner:蔡凤文

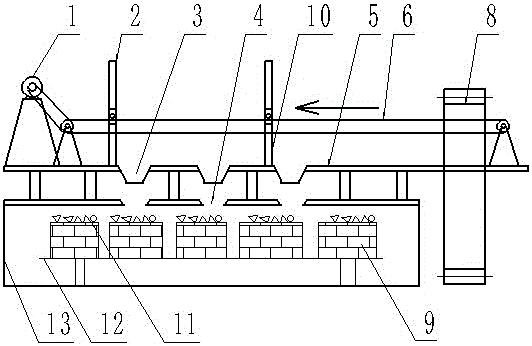

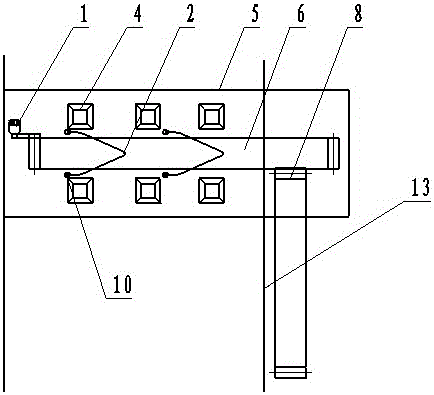

Method for producing quick lime through brickmaking waste heat

InactiveCN106338200AReduce outputReduce lossesFurnace typesCeramic materials productionComing outTunnel kiln

The invention discloses a method for producing quick lime through brickmaking waste heat. Green bricks are stacked on a kiln car and sequentially pushed into a tunnel kiln, the kiln car enters a green brick preheating segment after being dried through hot air in a moisture eliminating segment of the tunnel kiln, and limestone with the grain size ranging from 5 cm to 20 cm is paved to the top of a green brick stack from a kiln crown feeding hole; the temperature of a firing segment ranges from 900 DEG C to 1,200 DEG C, the standing time ranges from 2 h to 4 h, and the kiln car enters a cooling segment; and the kiln car comes out of the kiln after being cooled. According to the method for producing the quick lime through the brickmaking waste heat, a certain quantity of quick lime can be produced through the brick firing waste heat while the brick yield is not decreased. Heat energy losses are reduced, product varieties are increased, economic benefits are improved, and each kiln car can produce 1.8 ton of quick lime every day. Meanwhile, heat energy discharge is reduced, and the environment is protected.

Owner:JIEXIU UNIVERSE BUILDING MATERIALS CO LTD

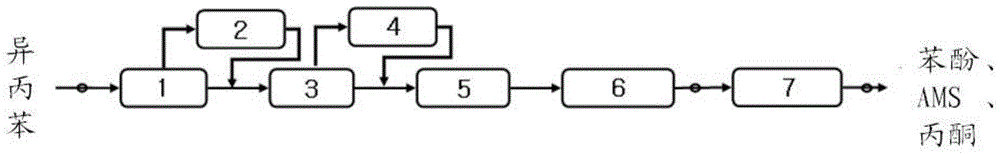

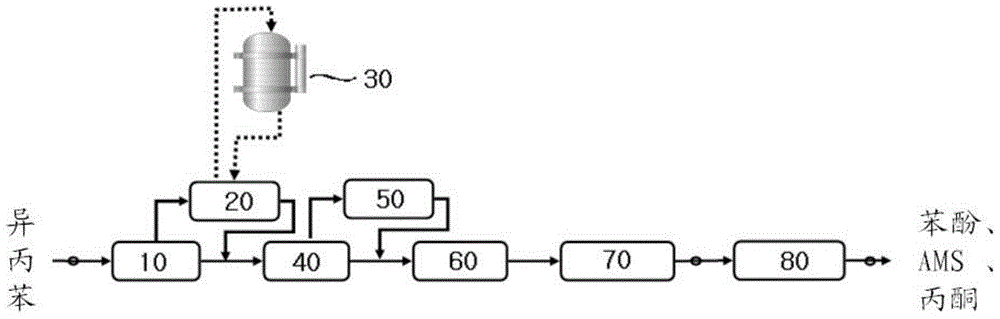

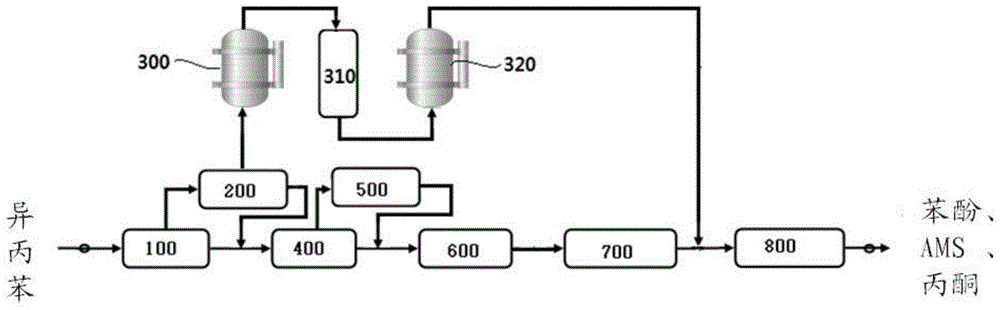

Method of preparing cumyl alcohol and method of preparing phenol, acetone and alpha-methyl styrene

ActiveCN103562168AReduce the risk of explosionIncrease conversion rateOrganic compound preparationCatalystsAlcoholHydrogenation process

The present invention relates to a method of preparing cumyl alcohol and a method of preparing phenol, acetone and alpha methyl styrene. According to the present invention, through a hydrogenation process for cumene hydroperoxide obtained by oxidizing cumene in a phenol preparing process, selectivity may be improved and the amount of cumyl alcohol may be increased. In addition, the amount of the alpha methyl styrene may be selectively increased. Further, the produced amount of the alpha methyl styrene may be controlled according to market demand by controlling the amount of the cumene hydroperoxide.

Owner:LG CHEM LTD

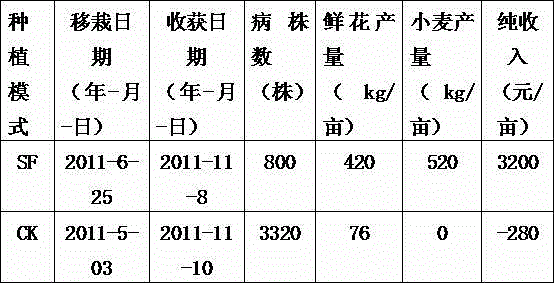

Ecological control method for Chuzhou chrysanthemum continuous cropping obstacles

The invention discloses an ecological control method for Chuzhou chrysanthemum continuous cropping obstacles. In order to overcome the continuous cropping obstacles caused by the situation that Chuzhou chrysanthemums are planted on the same land in successive years, a method for cultivation of disease-free strong seedlings and multiple cropping and crop rotation of chrysanthemums and wheat is adopted, regulation and intervention are performed in an ecological manner, and a good effect is achieved.

Owner:ANHUI SCI & TECH UNIV

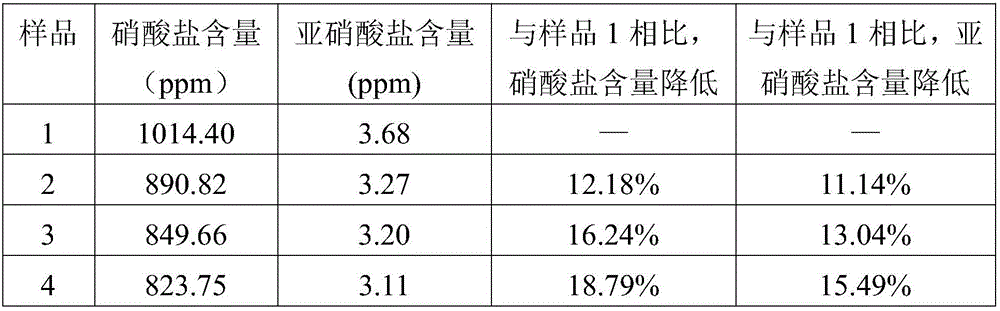

Special fertilizer for preserved Szechuan pickle, and preparation method thereof

ActiveCN106348915APromote growthGrowth inhibitionAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPolyaspartic acidNitrite

The invention discloses a special fertilizer for preserved Szechuan pickle, which comprises the following components in percentage by weight: 25-50% of a base fertilizer (based on the sum of N, P2O5 and K2O), 0.2-20% of a synergist and 1-3% of a nitrification inhibitor, wherein the weight ratio of N to P2O5 to K2O in the base fertilizer is (1.8-2.2):(0.9-1.1):(1.1-1.3). The synergist is polyaspartic acid salt, and the nitrification inhibitor is one of or mixture of more of sodium benzoate, 3,4-dimethylpyrazole phosphate, 2-chloro-6-tri(chloromethylpyridine), dicyandiamide, resorcinol and borax. By introducing the polyaspartic acid salt and nitrification inhibitor into the base fertilizer, the utilization rate of the preserved Szechuan pickle on the nutritional elements of the fertilizer can be improved, the loss of nitrogen in soil can be slowed down, finally the increment of the preserved Szechuan pickle can be realized through the disposable fertilizer application, and the contents of nitrates and nitrites in the preserved Szechuan pickle can be effectively controlled.

Owner:重庆建峰新材料有限责任公司

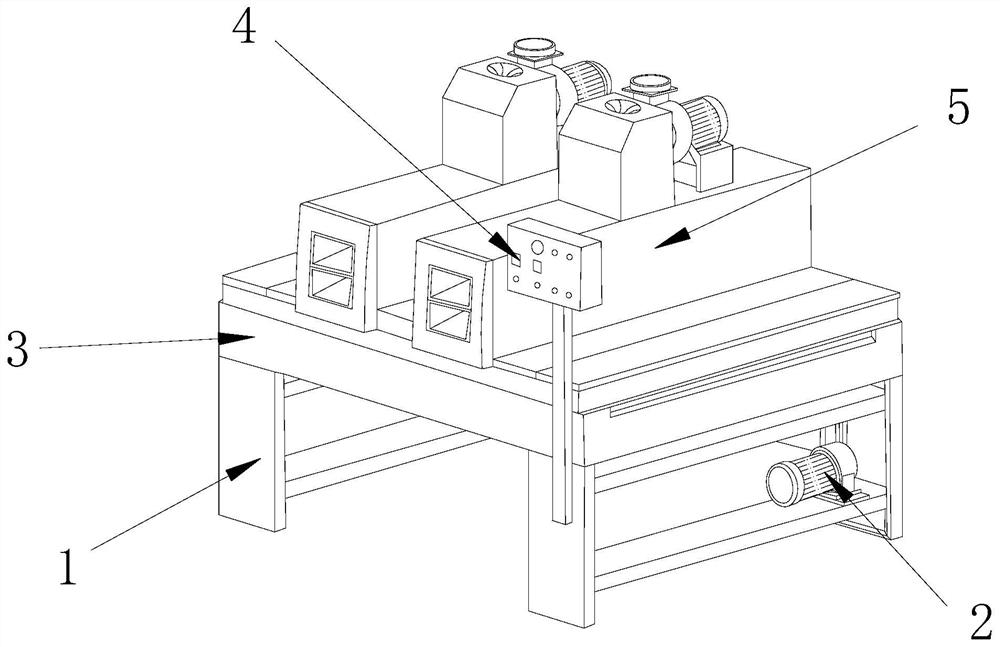

Plastic particle raw material drying machine for plastic product production

InactiveCN112109236ANo reduction in outputAvoid stickinessConveyor partsComposite materialManufacturing engineering

The invention discloses a plastic particle raw material drying machine for plastic product production. The plastic particle raw material drying machine structurally comprises a bracket, a driving machine, a heating seat, a console and a dryer, the top end of the bracket is welded to the bottom of the heating seat, the bottom of the driving machine is fixedly installed at the middle section of thebracket, and the rear face of the console and the front face of the heating seat are fixedly installed. The bottom face of the dryer is fixedly connected with the top face of the heating seat. Beforeplastic particle raw materials are fed into the drying machine to be dried, large blocky particles and small powder particles are separated through a separation bin first, then the large particles areseparated to be dried, and the small powder particles are conveyed to the lower layer to be melted, formed and then conveyed out. Not only can the small powder particles be prevented from being melted and adhering to a conveying belt in the drying process, but also the output quantity of the dried plastic raw materials cannot be reduced.

Owner:项海燕

sheet metal bending machine

A metal sheet bending machine, comprising: a main bending tool member (2; 6) extending along a longitudinal direction (A) and movable for bending a workpiece (50); and the main bending tool member (2; 6) ) an associated and parallel guide member (3) extending through the working area (W) of the bending machine (1) and protruding laterally from the bending machine at least with a first end portion (4); and Shuttle members (21, 22, 23) slidably mounted on said guide member (3) and supporting at least one auxiliary tool (41, 42) for association with said main bending tool member (2; 6) , thereby performing a partial bending of the workpiece (50); the shuttle member (21, 22, 23) can be in a first active position (P1) and a first inactive position (R1) along the longitudinal direction (A) ), wherein in the first active position, the shuttle members (21, 22, 23) are located inside the working area (W), and the auxiliary tools (41, 42) are mounted on the main bending tool member (2; 6), while in said first inactive position said shuttle member (21, 22, 23) is located outside said working area (W) and positioned on said guide member (3) at the first end portion (4) of 41, 42), the shuttles (21, 22, 23) are connected to each other to form a first shuttle group (13) with an optional number of shuttles (21, 22, 23); the first shuttle group ( 13) Moveable between the first inactive position (R1) and the first active position (P1) in order to mount the defined assembly of auxiliary tools (41, 42) on the main bending tool On component (2;6).

Owner:SALVAGNINI ITAL

Method for reducing nitrogen and phosphorus non-point source pollution of dry land

ActiveCN103071671BEmission reductionNo reduction in outputContaminated soil reclamationCompound (substance)Soluble nitrogen

The invention discloses a method for reducing nitrogen and phosphorus non-point source pollution of dry land, which comprises the following steps: firstly, taking FGD (Flue Gas Desulfurization) gypsum for fastening excessive phosphorus of dry land soil, thereby reducing runoff loss of soluble phosphorus and realizing the emission reduction for the in-situ phosphorus in a farmland; secondly, constructing a channel pond wetland system and performing biological fixation and efficient nitrogen and phosphorus removal; and lastly, fertilizing wetland plants and returning to the field, thereby reducing the investment of chemical fertilizer soluble nitrogen and phosphorus. According to the method, the resisting control is simultaneously performed at three aspects of generating process, period after running off and pollution source, so that the purpose of controlling the nitrogen and phosphorus pollution of the dry land is achieved. According to the method provided by the invention, the in-situ emission reduction for the phosphorus in the soil, the aquatic plant wetland adsorption and the organic fertilizer replacing local chemical fertilizer are combined, and the non-point source pollution of the dry land is simultaneously resisted and controlled at the three aspects of generating process, period after running off and pollution source, so that the purpose of effectively preventing and controlling the nitrogen and phosphorus pollution of the farmland is achieved, the recycling for the waste resources is realized, and the method has extensive application prospect.

Owner:JIANGSU ACAD OF AGRI SCI

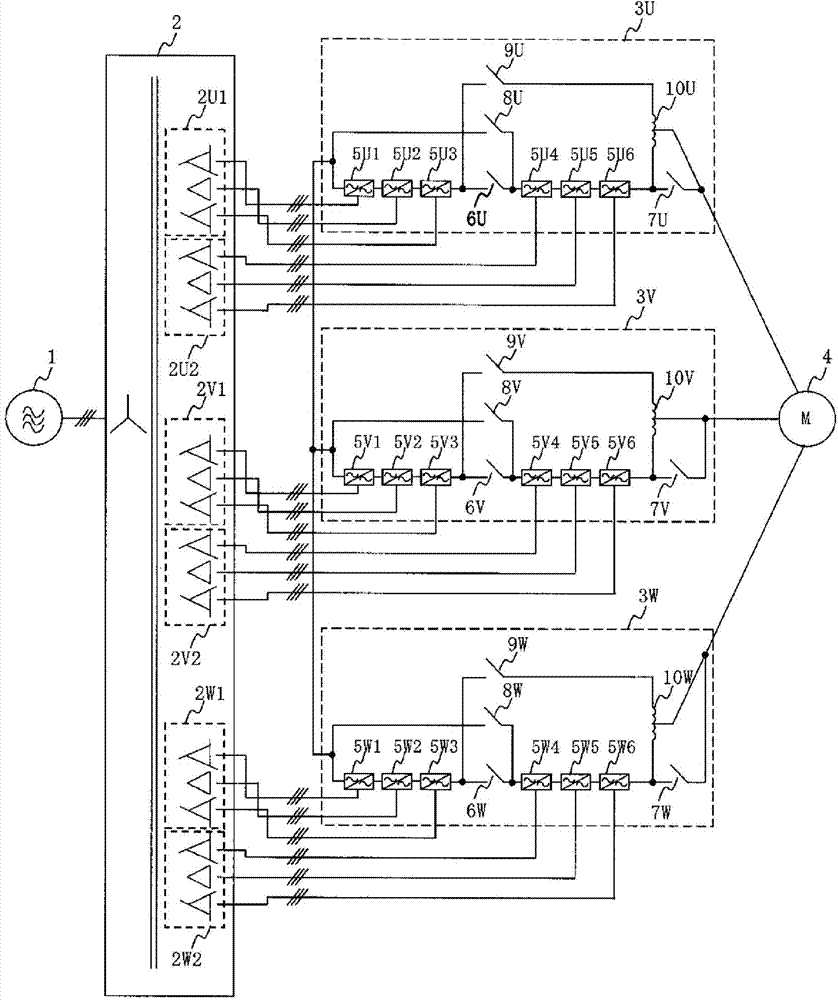

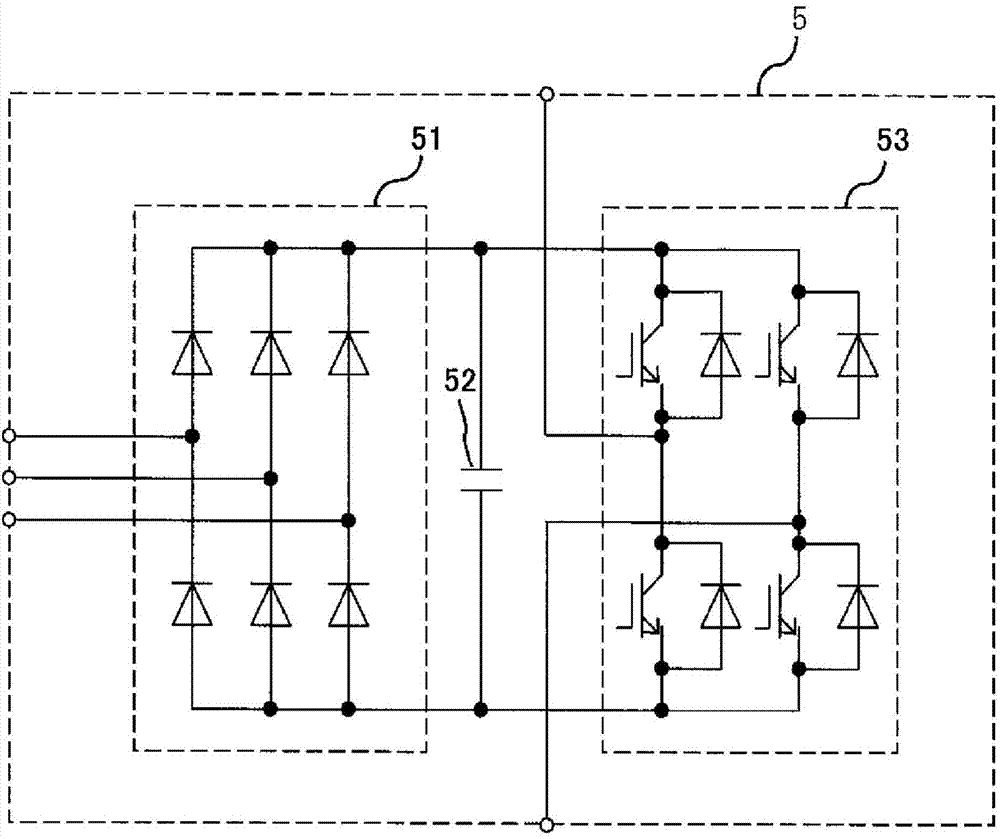

Power conversion device

ActiveCN103947098AReduce outputNo reduction in outputDc-ac conversion without reversalPower inverterTransformer

Provided is a power conversion device whereby different voltage classes can be outputted by a single power conversion device without reducing the rated capacity. The present invention is configured from: an input transformer (2) having 3 K (where K is an integer of 2 or greater) secondary coils, an alternating-current power source (1) being connected to a primary coil; and three power conversion units (3) connected one-each to the secondary coils and configured so as to each output three-phase phase voltage using K unit inverters (5) for outputting single-phase alternating-current voltage at a desired frequency. The power conversion units (3) are configured so as to be switched between a series-connection mode for connecting the outputs of the K unit inverters (2) in series, and a parallel-connection mode for dividing the K unit inverters into a plurality of groups, connecting the outputs of the unit inverters within each group in series, and connecting the outputs of the plurality of inverter groups in parallel.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

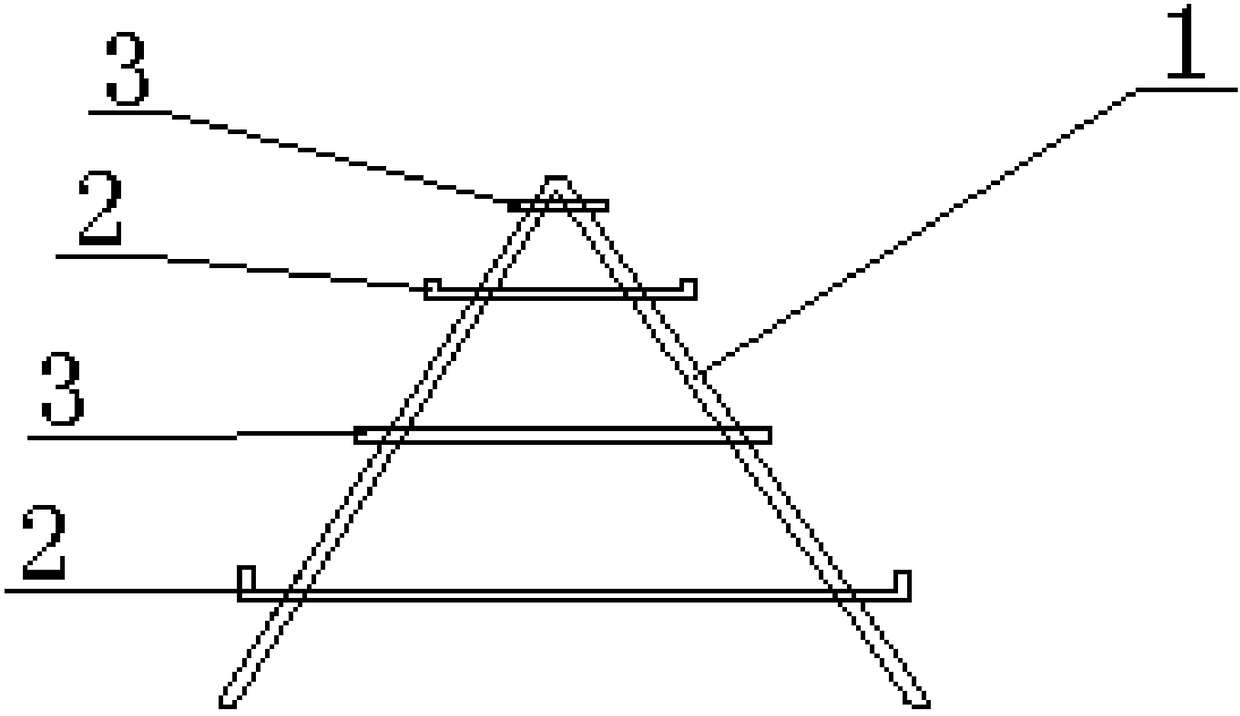

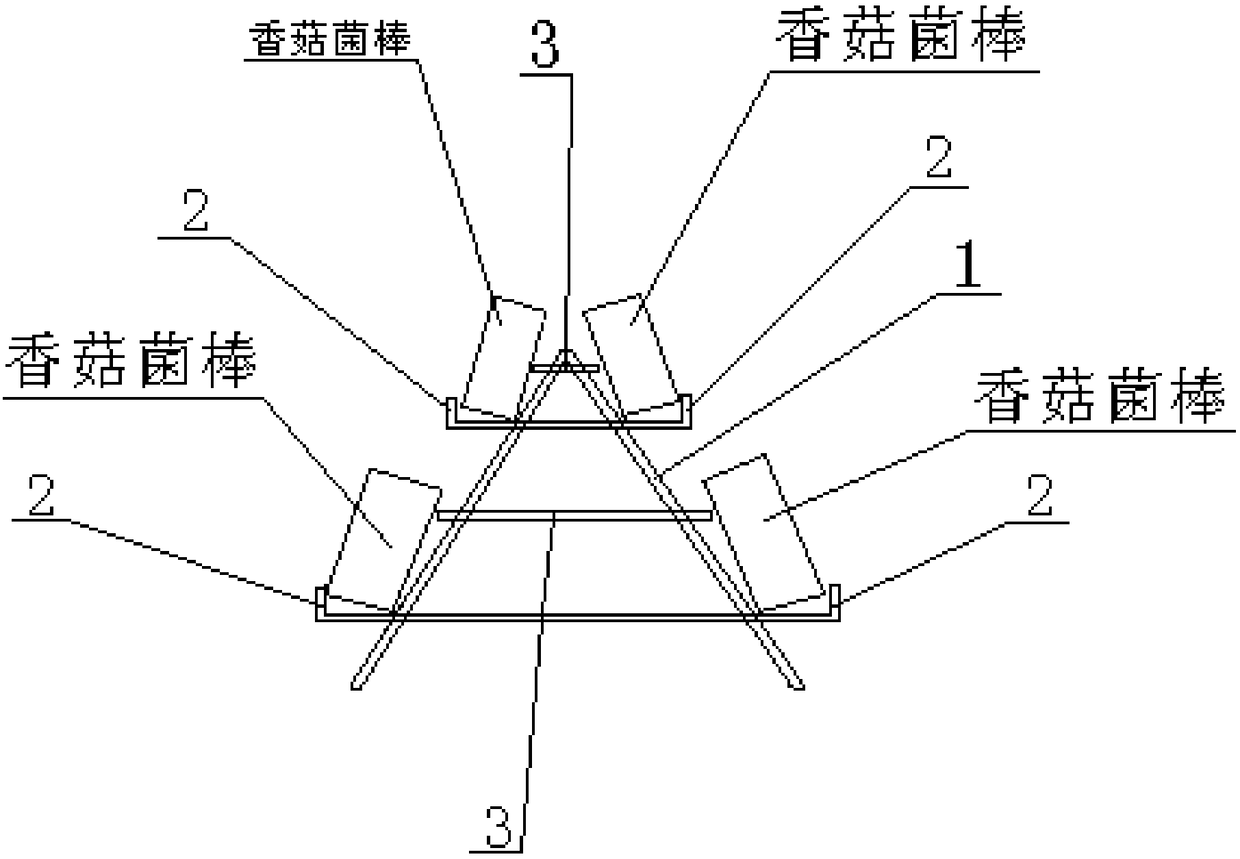

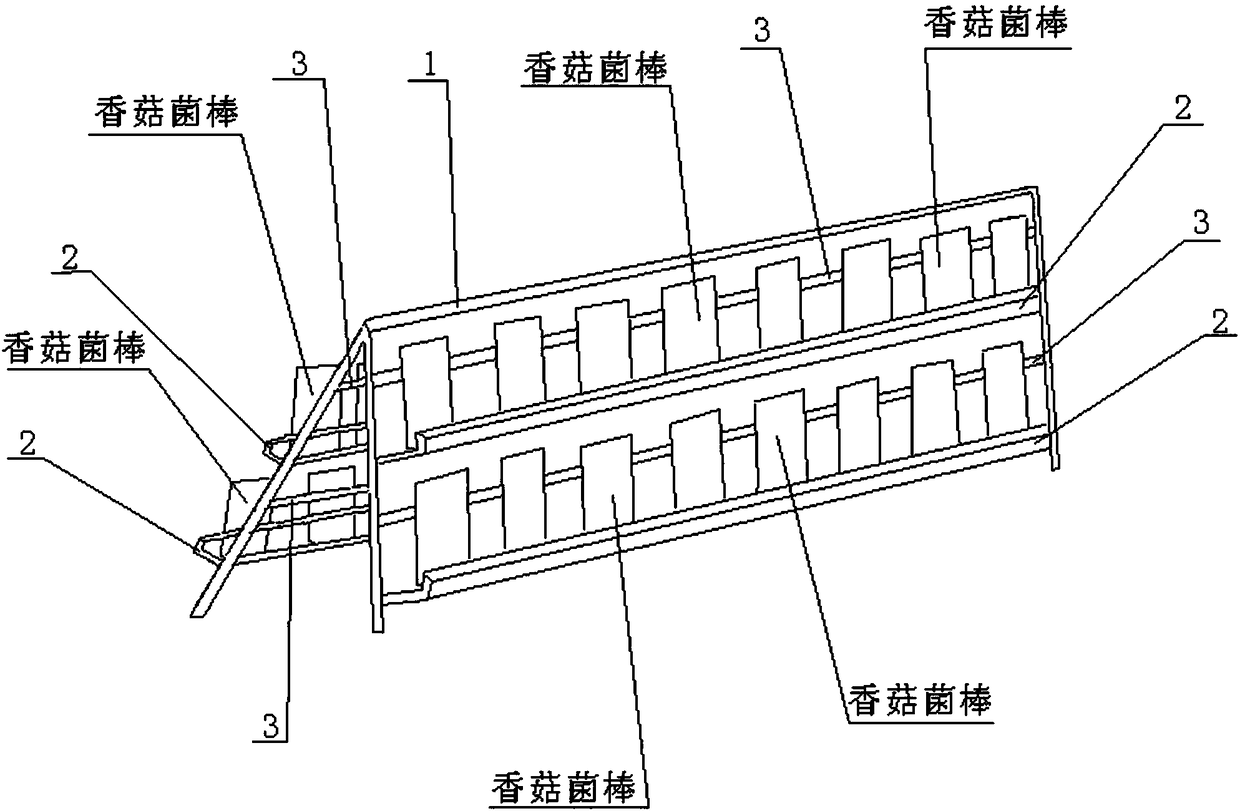

Method for manufacturing mushroom bacteria sticks from mango branches and leaves and performing stereo-cultivation of mushrooms under mango trees

InactiveCN108184538AMeasures uniqueThe method is simpleCultivating equipmentsMushroom cultivationShiitake mushroomsHyphomycetes

The invention discloses a method for manufacturing mushroom bacteria sticks from mango branches and leaves and performing stereo-cultivation of mushrooms under mango trees. The method comprises the steps that a stereo-cultivation frame is constructed under mango trees, trimmed mango branches and leaves are adopted as main raw materials for manufacturing mushroom bacteria sticks, and stereo-cultivation and fruiting management of the mushroom bacteria sticks under the mango trees are performed. According to the method, a large number of originally waste mango branches and leaves are converted and utilized, an industry chain is prolonged, and values of agricultural resources are added in multiple stages. The stereo-cultivation frame is constructed under the mango trees and filled with the mushroom bacteria sticks, the space utilization rate is larger, under the mango trees, the environment with the low temperature and humidity facilitating hypha and sporocarp growth can be more easily built for the mushroom bacteria sticks, the mushroom conversion rate is higher, and the quality is better. Stereo-cultivation of mushroom is performed under the mango trees, management is more convenient, during fruiting, the space under the mango trees is filled with mushrooms, the scene is spectacular, and the beautiful scenery line is added to sightseeing tour.

Owner:田东县举家富现代农业开发有限公司

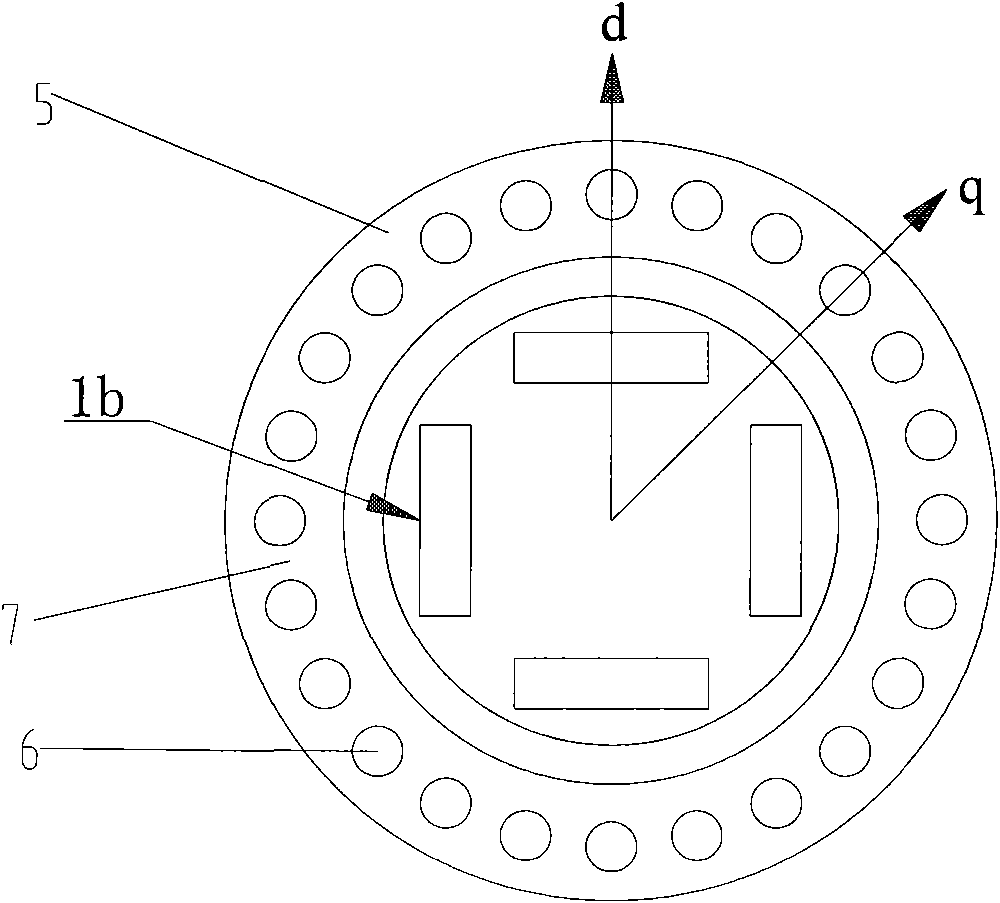

Rotor for permanent magnet synchronous motor and permanent magnet synchronous motor

PendingCN114744790ASmall torqueLow noise and vibrationSynchronous machine detailsMagnetic circuit rotating partsElectric machinePermanent magnet synchronous motor

The invention discloses a rotor for a permanent magnet synchronous motor and the permanent magnet synchronous motor. The rotor for the permanent magnet synchronous motor comprises a rotor iron core, the rotor iron core is provided with a plurality of magnetic pole grooves extending along the axial direction, and permanent magnets extending along the axis are arranged in the magnetic pole grooves; the outer surface of the rotor core is provided with a plurality of auxiliary grooves, and the auxiliary grooves and the magnetic pole grooves are mutually independent; and the auxiliary groove has a deviation angle. By adopting the scheme, the cogging torque of the motor can be reduced, the air gap flux density waveform can be corrected, the sine degree of the back electromotive force waveform can be improved, noise vibration caused by defects of the motor body can be reduced, and the electromagnetic performance of the motor can be improved. According to the scheme, the increase of assembly procedures caused by a traditional rotor skewed pole can be avoided, meanwhile, the structural strength of the motor rotor punching sheet is not influenced, more effects of selecting the position and the axial shape of the auxiliary groove are not influenced, and in some specific positions, the noise and vibration performance of the motor can be improved, and the output of the motor is not reduced or even improved.

Owner:XIAMEN TUNGSTEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com