Method for manufacturing semiconductor device

A manufacturing method, semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problem of deteriorating tantalum oxide film step coverage, poor film quality capacitive insulating film, impossible to form capacitive insulating film, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

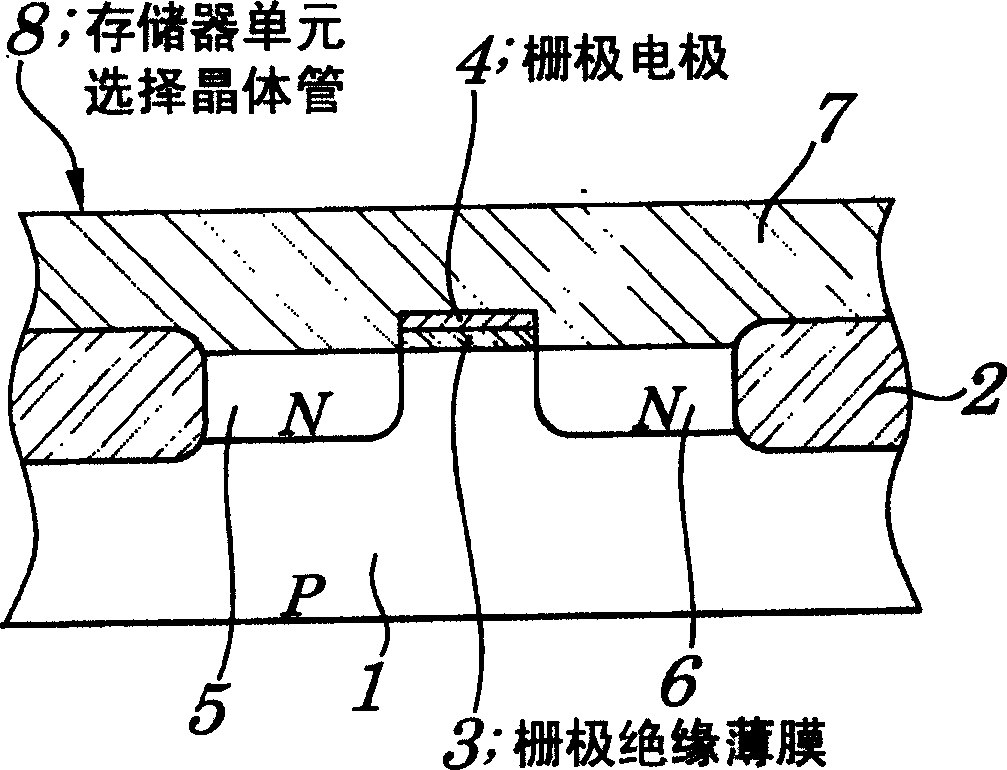

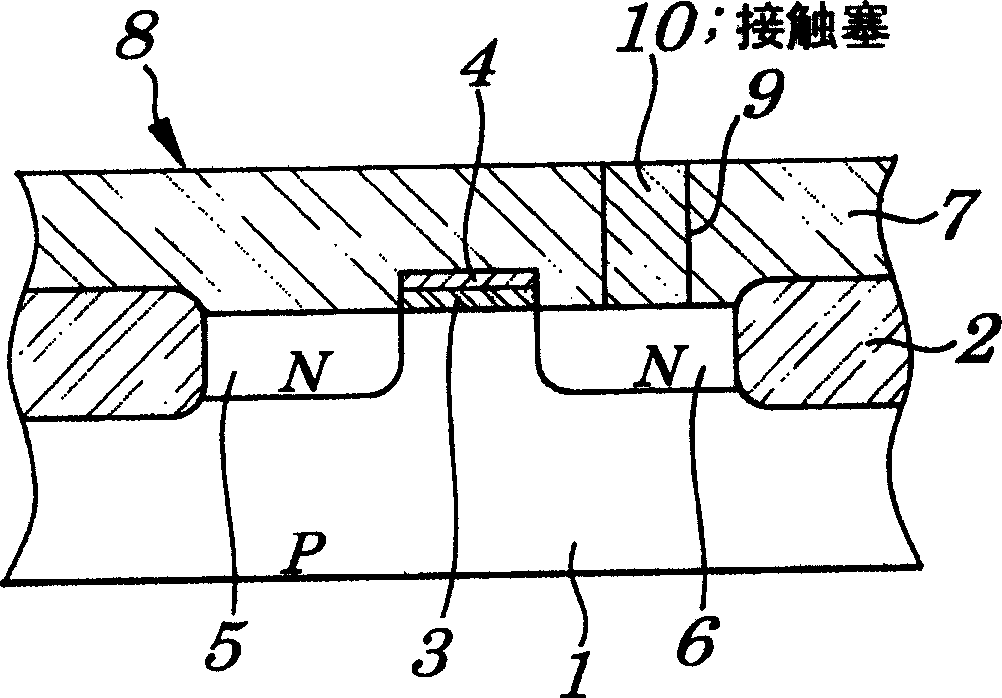

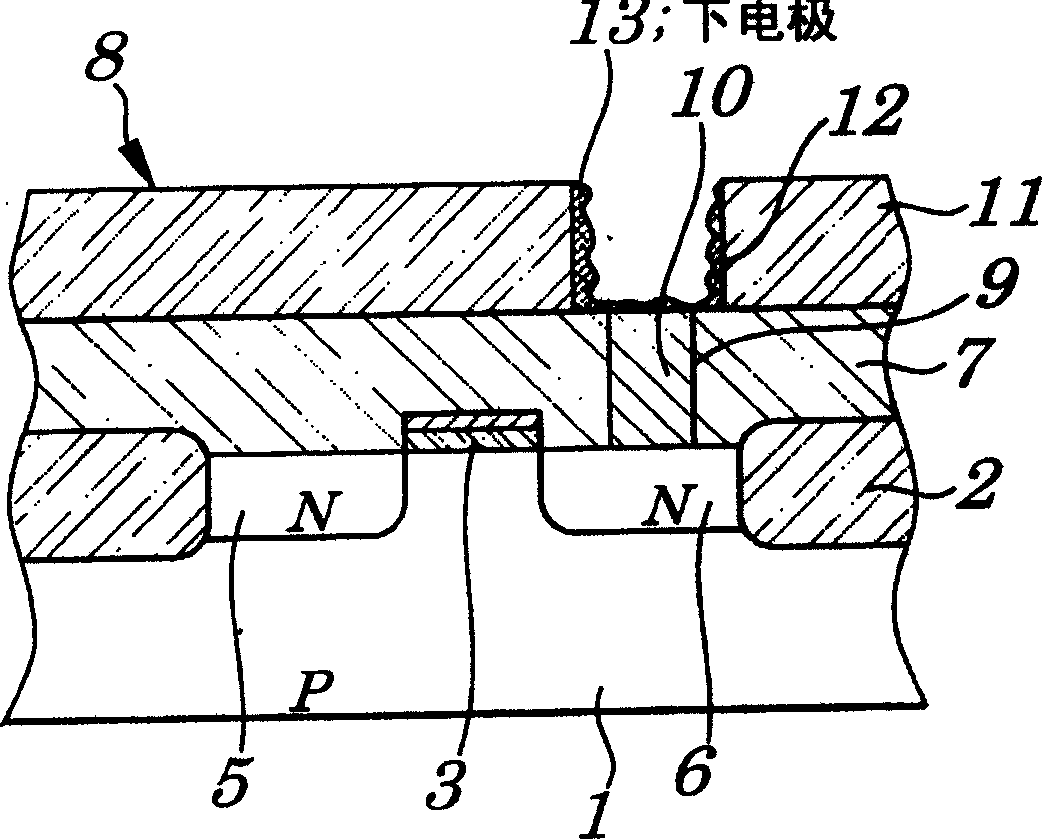

[0066] The following will refer to Figures 1A-1E and figure 2 , the method of manufacturing the semiconductor device according to the first embodiment will be described.

[0067] First, if Figure 1A As shown, for example, an element isolation region 2 is formed by using a P-type semiconductor substrate 1 by a known method such as LOCOS (Local Oxidation of Silicon) or STI (Shallow Trench Isolation), thereby forming an element isolation region 2 in the center of each active region. A gate insulating film 3 made of, for example, a silicon oxide film, and a gate electrode 4 made of, for example, a polysilicon film. Next, by utilizing self-alignment of the gate electrode 4, ions of N-type impurities are implanted to form a pair of N-type regions 5 and 6 respectively serving as source regions and drain regions; A first interlayer insulating film 7 composed of the same, to form a memory cell selection transistor 8 composed of an N-type MOS (NMOS) transistor.

[0068]Next, if ...

no. 2 example

[0078] The semiconductor device manufacturing method of this embodiment is very different in structure from the semiconductor device manufacturing method of the first embodiment, in which the two-stage deposition step ST described in the principle paragraph is repeated three times to finally form a tantalum oxide film, the oxide The tantalum film constitutes the capacitive insulating film and has a final desired film thickness (10 nm, the same value as that of the first embodiment). The following will refer to image 3 This semiconductor device manufacturing method is described.

[0079] That is, in the first embodiment Figure 1D in the process, according to image 3 A tantalum oxide film is formed in a sequence of depositions to form a capacitive insulating film 14 made of a tantalum oxide film on the lower electrode 13 .

[0080] With the structure of the second embodiment, the two-stage deposition step ST described in the principle paragraph was repeated three times to ...

no. 3 example

[0085] The structure of the semiconductor device manufacturing method of this embodiment is very different from the semiconductor device manufacturing method of the first embodiment, wherein when the two-stage deposition step ST is repeated twice to finally form a In the case of the same 10nm) tantalum oxide film, as described in the principle paragraph, at the first extreme S1 of each deposition step ST, in addition to the raw material gas, a small amount of oxygen is introduced. In this case, the amount of oxygen introduced in the first stage is chosen in such a way that the coverage is not deteriorated. The following will refer to Figure 4 A semiconductor device manufacturing method is described.

[0086] That is, in the first embodiment Figure 1D in the process, according to Figure 4 A tantalum oxide film is formed in a sequence of depositions to form a capacitive insulating film 14 made of a tantalum oxide film on the lower electrode 13 .

[0087] With the structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com