Plastic particle raw material drying machine for plastic product production

A technology of plastic granules and plastic products, which is applied in the direction of conveyor objects, transportation and packaging, and can solve the problems of reducing the output of plastic raw materials, varying shapes, and difficult cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

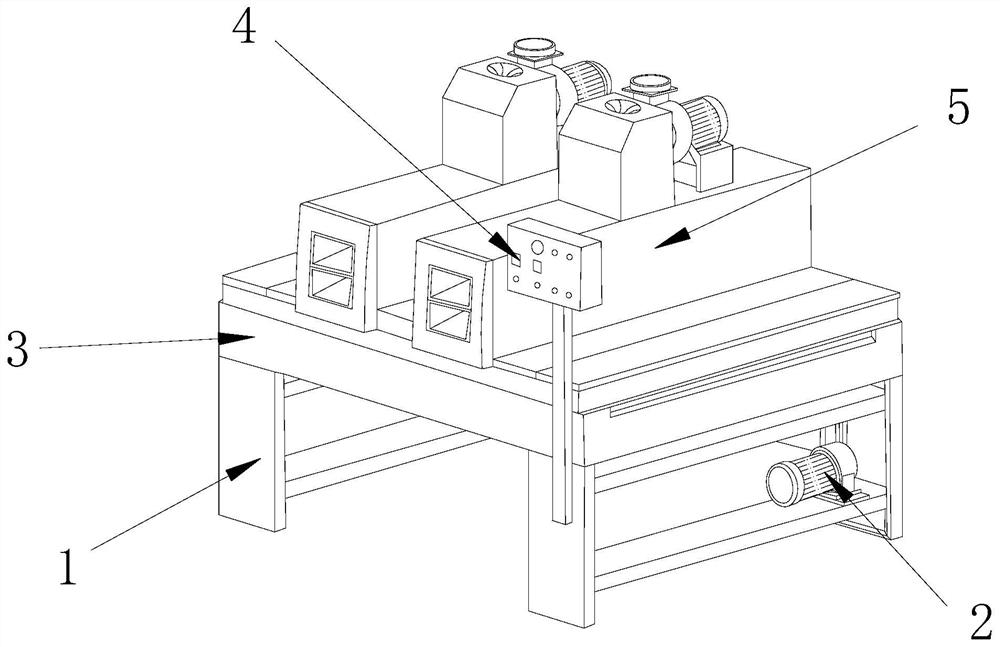

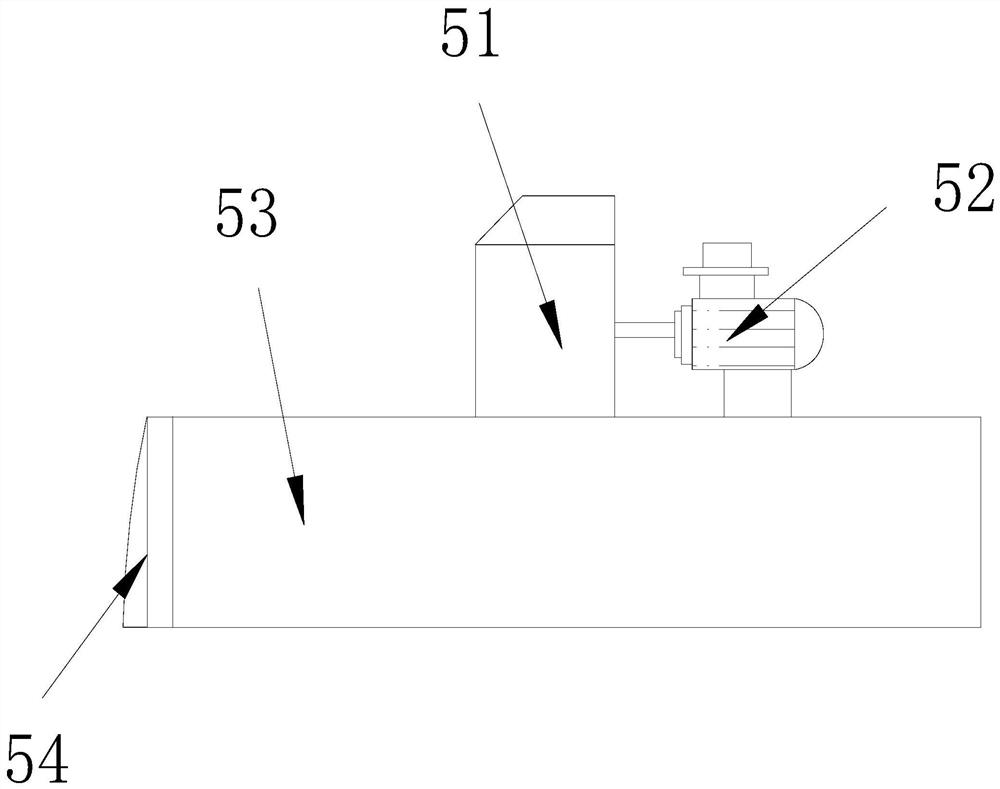

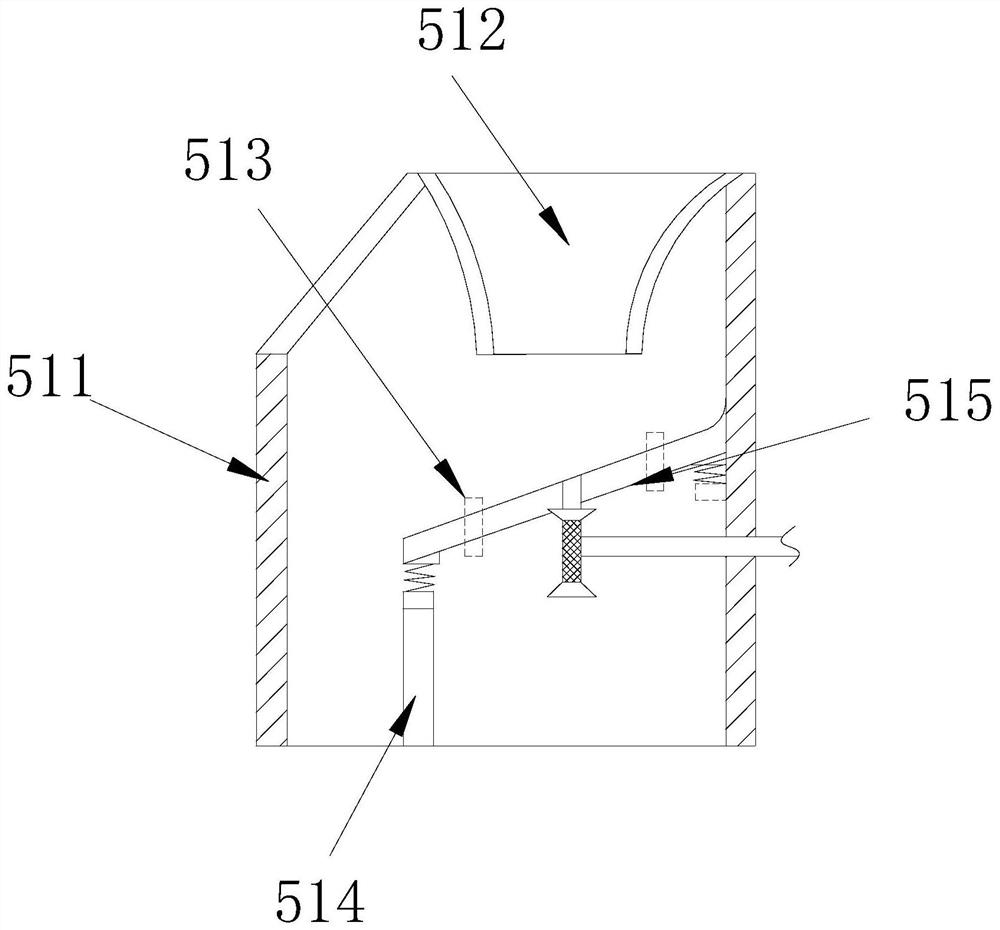

[0028] see Figure 1-Figure 6 , the specific embodiments of the present invention are as follows: a plastic particle raw material dryer for the production of plastic products, its structure includes a bracket 1, a driver 2, a heating seat 3, a console 4, a dryer 5, the top of the bracket 1 is connected to the heating The bottom of the seat 3 is welded and connected, the bottom of the driver 2 is fixedly installed in the middle section of the bracket 1, the rear of the console 4 is fixedly installed with the front of the heating seat 3, and the bottom surface of the dryer 5 is fixedly connected with the top surface of the heating seat 3; The dryer 5 includes a separation bin 51, a vibrator 52, a transport recovery device 53, and an output cover 54. The right side of the separation compartment 51 is movably engaged with the left side of the vibrator 52, and the top of the transport recovery device 53 is connected to the separation bin. The bottoms of the 51 are connected to each...

Embodiment 2

[0035] see Figure 7-Figure 9 , the specific embodiment of the present invention is as follows: the transport recoverer 53 includes a housing 531, a normal inlet 532, a first conveyor belt 533, a powder inlet 534, a powder recovery machine 535, a pusher 536, a power supply 537, and a second conveyor belt 538, The top of the housing 531 is integrally formed with the normal inlet 532, the two sides of the first conveyor belt 533 are movably engaged inside the housing 531, the powder inlet 534 is integrally formed with the top of the housing 531, and the The powder recovery machine 535 is fixedly installed inside the housing 531, the left side of the pusher 536 is fixedly connected to the right side of the powder recovery machine 535, the outer layer of the power supply 537 is fixedly installed inside the housing 531, and the second conveyor belt 538 The side is movably engaged with the inner layer of the housing 531, and the powder inlet 534 has a circular truncated structure, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com