Laminate for nonaqueous battery

A technology for non-aqueous batteries and laminates, which is applied in the direction of non-aqueous electrolytes, secondary batteries, battery components, etc., and can solve problems such as lack of cross-linking treatment, extrusion of pressure-sensitive adhesive layers, and insufficient adhesive strength, etc. problem, achieve the effect of improving applicability, suppressing deterioration, and preventing short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

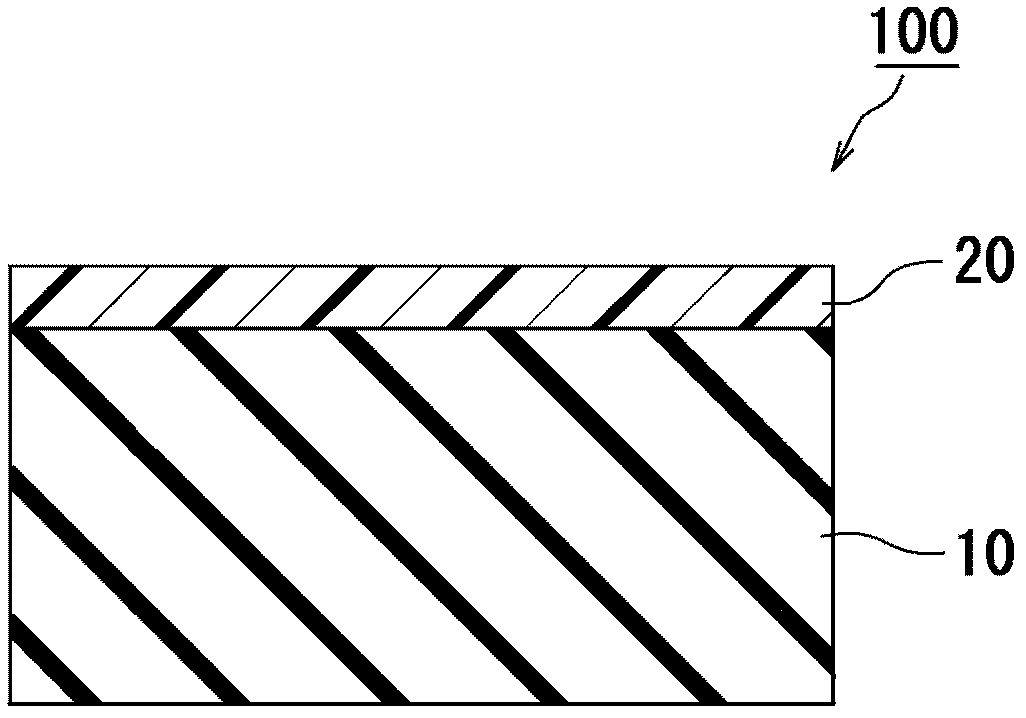

[0146] Block PP (PC480A, manufactured by SunAllomer Ltd., MFR=1.7 (230° C., 2.16 kgf)) as the substrate layer and an α-olefin-based pressure-sensitive adhesive (Tafthren H5002, Sumitomo Chemical Company, Limited) was loaded into an extruder, and then melt-extruded by an inflation molding method. Thus, a laminate (1) for a non-aqueous battery (thickness: substrate layer / pressure-sensitive adhesive layer=30 μm / 10 μm) was produced.

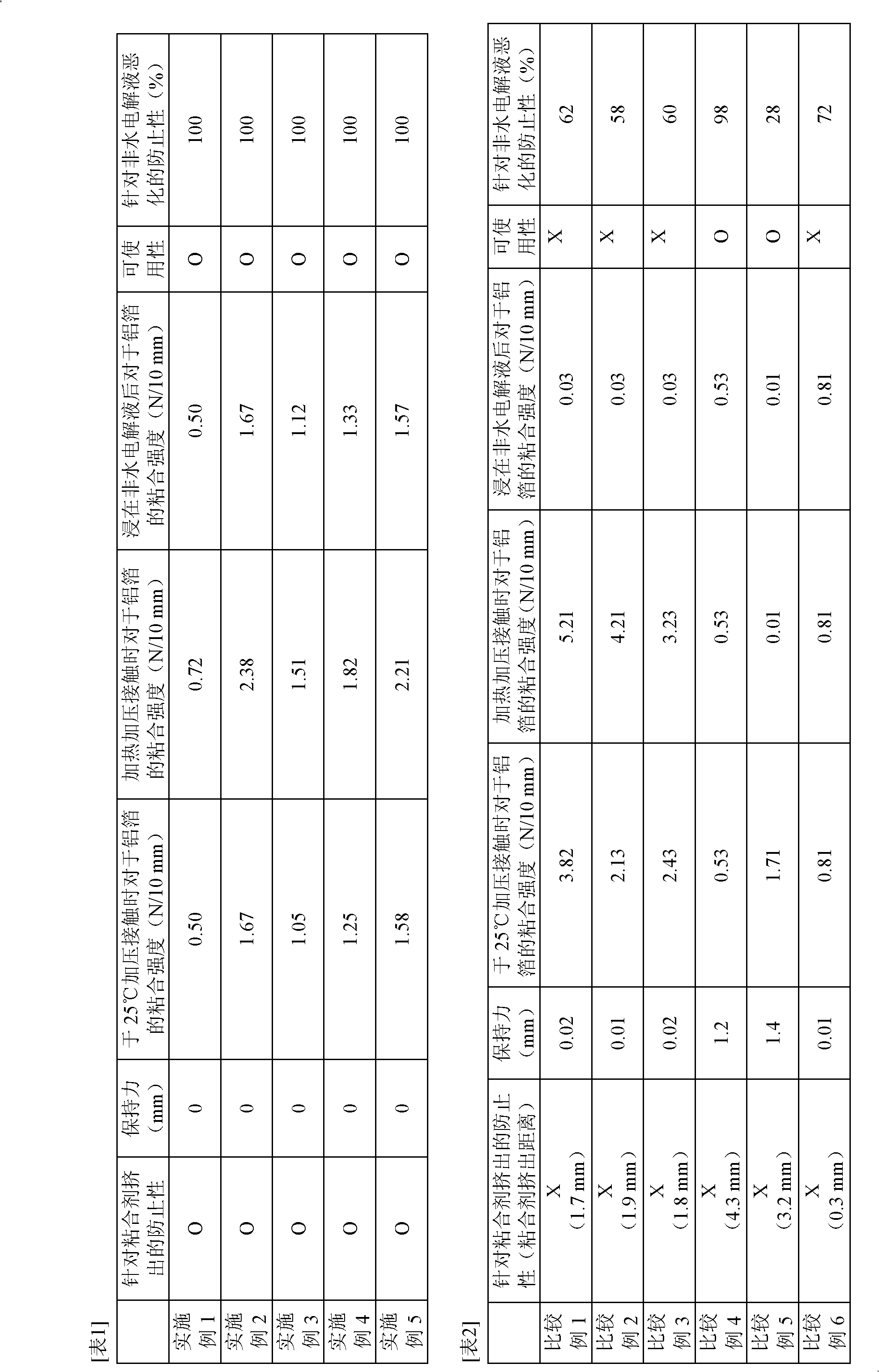

[0147]Table 1 shows the evaluation results.

Embodiment 2

[0149] Block PP (PC480A, manufactured by SunAllomer Ltd., MFR=1.7 (230° C., 2.16 kgf)) as the substrate layer and 100 parts by weight of α-olefin-based pressure-sensitive adhesive (Tafthren H5002, manufactured by Sumitomo Chemical Company, Limited) and 30 parts by weight of ARAKAWA CHEMICAL INDUSTRIES, Ltd. The product obtained by mixing the tackifier "ARKON P-125" was charged into the extruder, and then passed through the blown Molding method for melt extrusion. Thus, a laminate (2) for a non-aqueous battery (thickness: substrate layer / pressure-sensitive adhesive layer=30 μm / 8 μm) was produced.

[0150] Table 1 shows the evaluation results.

Embodiment 3

[0152] Block PP (PC480A, manufactured by SunAllomer Ltd., MFR=1.7 (230° C., 2.16 kgf)) as the substrate layer and 100 parts by weight of α-olefin-based pressure-sensitive adhesive (Tafthren H5002, manufactured by Sumitomo Chemical Company, Limited) and 15 parts by weight of ARAKAWA CHEMICAL INDUSTRIES, Ltd. The product obtained by mixing the tackifier "ARKON P-125" was charged into the extruder, and then passed through the blown Molding method for melt extrusion. Thus, a laminate ( 3 ) for a non-aqueous battery (thickness: substrate layer / pressure-sensitive adhesive layer=30 μm / 8 μm) was produced.

[0153] Table 1 shows the evaluation results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com