Method of preparing cumyl alcohol and method of preparing phenol, acetone and alpha-methyl styrene

A technology of methyl styrene and cumene, which is applied in the preparation of acetone and α-methyl styrene, and the field of preparation of phenol and cumene, can solve deficiencies, increase the output of α-methyl styrene, etc. problems, to ensure stability, reduce the risk of explosion, and increase the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

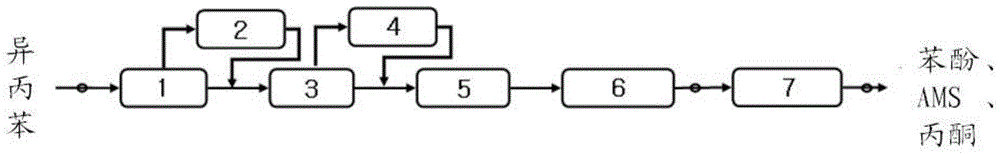

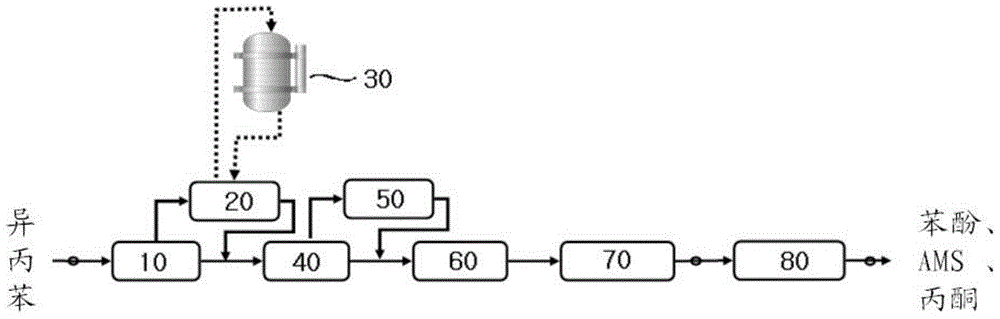

Method used

Image

Examples

Embodiment 1

[0134] Pd-Co / C is filled as a catalyst in the hydrogenation reactor, hydrogen gas is injected, and the internal temperature is maintained to carry out the reaction. A stream of cumene hydroperoxide having a concentration of 25% by weight was injected as a reactant from the bottom-up of the reactor using a booster pump. The hydrogenation reaction was carried out by injecting 150 g of a stream of cumene hydroperoxide (CHP) at a concentration of 25% by weight and 1 g of a Pd—Co / C catalyst with a weight ratio of Pd:Co of 1:1. Also, the molar ratio of cumene hydroperoxide flow and injected hydrogen was maintained at 1:8. The reaction was carried out for three hours.

Embodiment 2 to 5

[0136] Except using the Pd-Co / C catalyst which changed the weight ratio of Pd:Co, it is the same as Example 1. The weight ratio of Pd:Co is shown in Table 1 below.

[0137]

[0138]

Embodiment 6

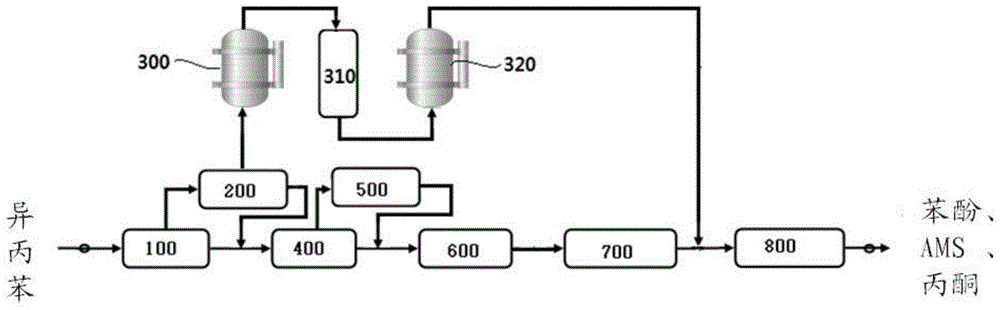

[0140] according to figure 2 The process flow diagram shown produces phenol, acetone and alpha-methylstyrene.

[0141] First, three oxidation reactors were used in the phenol process, and the oxidation of cumene using an oxidizing agent was carried out under the following conditions to prepare cumene hydroperoxide (CHP) containing cumene hydroperoxide (CHP) at a concentration of 25% by weight. of cumene hydroperoxide stream.

[0142] (1) Conditions for putting in the first oxidizer

[0143] Supply (CHP0.4% + cumene 99.6%) 1ml / min, O 2 : 100ml / min, pressure: 3bar, reaction temperature: 100℃

[0144] (2) Conditions for adding the second oxidizer

[0145] Supply (CHP8.42% + cumene 91.58%) 1ml / min, O 2 : 100ml / min, pressure: 3bar, reaction temperature: 96℃

[0146] (3) Conditions for adding the third oxidizer

[0147] Supply (CHP16.27% + cumene 83.73%) 1ml / min, O 2 : 100ml / min, pressure: 3bar, reaction temperature: 94℃

[0148] At this point, the concentration of the CHP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com