Slow injection and pressurization pressure-casting process

A process and pressure-increasing technology, which is applied in the field of slow-shot pressurized die-casting technology, can solve problems such as inability to guarantee production requirements, frequent mold sticking, and unsmooth production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

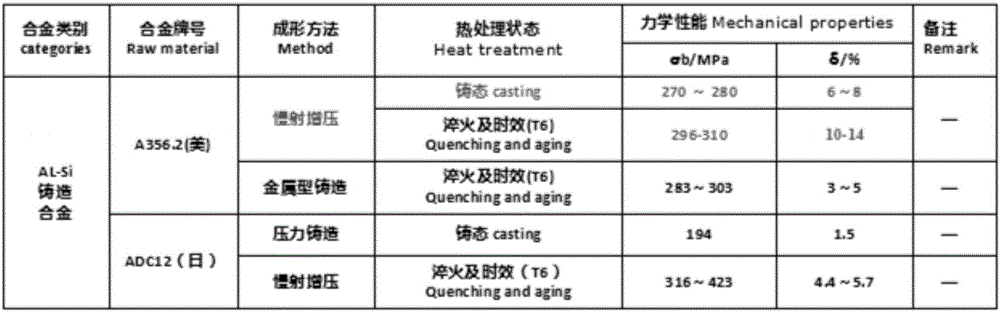

[0044] This embodiment provides a slow-shot pressurized die-casting process, which uses aluminum alloy 356.2 as a raw material to obtain an automobile brake system bracket through die-casting;

[0045] Die casting includes the following steps:

[0046] 1) Low-speed step: The molten aluminum in the melting cup is fed at a low speed by a punch to fill the cavity;

[0047] 2) Supercharging step: make the molten aluminum advance at a low speed to fill the cavity and solidify to start the supercharging pressure;

[0048] 3) Injection molding: Injection is completed with injection time twice that of traditional injection.

[0049] The traditional injection time of traditional die casting is generally 0.3s-0.5s.

[0050] The speed of the low speed is 0.2m / s.

[0051] Step 2) in boosting pressure (aluminum liquid withstand pressure) is 80Mpa.

[0052] Carry out T6 heat treatment on the car brake system bracket;

[0053] Correspondingly, T4 heat treatment can also be used instead ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com