A kind of high-efficiency and energy-saving rice vermicelli preparation method

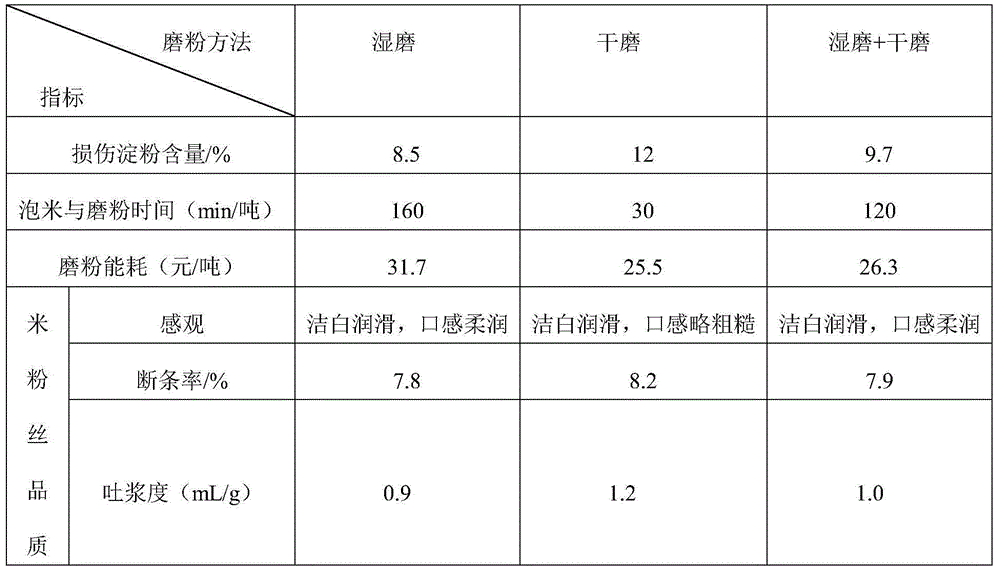

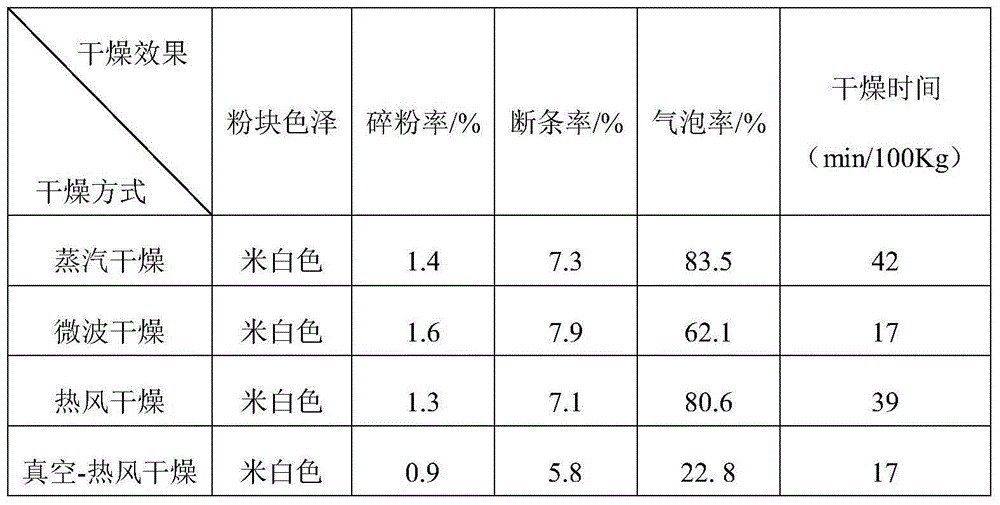

A high-efficiency energy-saving rice vermicelli technology is applied in food preparation, food shaping, food drying, etc. It can solve the problems of high energy consumption, high damaged starch content, and poor quality of rice vermicelli products, so as to reduce the energy consumption of milling, The effect of reducing the crushing rate and shortening the grinding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A high-efficiency and energy-saving rice vermicelli preparation method, comprising the following steps:

[0038] (1) Raw material processing: removing impurities and whitening rice raw materials;

[0039] (2) Grinding dry powder: a part of the rice raw material after removing impurities and whitening is dry ground into rice dry powder, and the obtained rice dry powder is passed through a 100-mesh sieve;

[0040] (3) Soaking and grinding rice milk: soak the remaining rice raw material after removing impurities and whitening with 4 times the weight of rice for 120 minutes, then grind it into rice milk, and pass the obtained rice milk through a 100-mesh sieve;

[0041] (4) dehydration: the rice milk obtained in step (3) is dehydrated, and after dehydration, the wet rice powder with a water content of 35wt% is obtained;

[0042] (5) Mixing and stirring: Pour dry rice powder and wet rice powder into the mixing steamer in a ratio of 1:3, then add a texture improver with an a...

Embodiment 2

[0049] A high-efficiency and energy-saving rice vermicelli preparation method, comprising the following steps:

[0050] (1) Raw material processing: removing impurities and whitening rice raw materials;

[0051] (2) Grinding dry powder: a part of the rice raw material after removing impurities and whitening is dry ground into rice dry powder, and the obtained rice dry powder is passed through a 120-mesh sieve;

[0052] (3) Soaking and grinding rice milk: soak the remaining rice raw material after removing impurities and whitening with 6 times the weight of rice for 160 minutes, then grind it into rice milk, and pass the obtained rice milk through a 120-mesh sieve;

[0053] (4) dehydration: the rice milk obtained in step (3) is dehydrated, and after dehydration, the wet rice powder with a water content of 40wt% is obtained;

[0054] (5) Mixing and stirring: Pour dry rice powder and wet rice powder into the mixing steamer in a ratio of 1:5, then add a texture improver with an a...

Embodiment 3

[0061] A high-efficiency and energy-saving rice vermicelli preparation method, comprising the following steps:

[0062] (1) Raw material processing: removing impurities and whitening rice raw materials;

[0063] (2) Grinding dry powder: a part of the rice raw material after removing impurities and whitening is dry ground into rice dry powder, and the obtained rice dry powder is passed through a 140 mesh sieve;

[0064] (3) Soaking and grinding rice milk: soak the remaining rice raw material after removing impurities and whitening with 8 times the weight of rice for 180 minutes, then grind it into rice milk, and pass the obtained rice milk through a 140-mesh sieve;

[0065] (4) dehydration: the rice milk obtained in step (3) is dehydrated, and after dehydration, the wet rice powder with a water content of 45wt% is obtained;

[0066] (5) Mixing and stirring: Pour dry rice powder and wet rice powder into the mixing steamer in the ratio of 2:5, then add a texture improver with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com