A low-expansion high-strength dental gypsum composition, its preparation process, use method and application

A composition, high-strength technology, applied in the fields of dentistry, dental prosthesis, medical science, etc., can solve the problem of dental gypsum fluidity, initial and final setting time expansion coefficient, and strength that cannot meet the requirements of restorations at the same time, and cannot guarantee dental Gypsum performance stability, failure to reach high-precision dental restoration models, etc., to achieve good rheology and operability, shorten the setting time, and stabilize various performances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

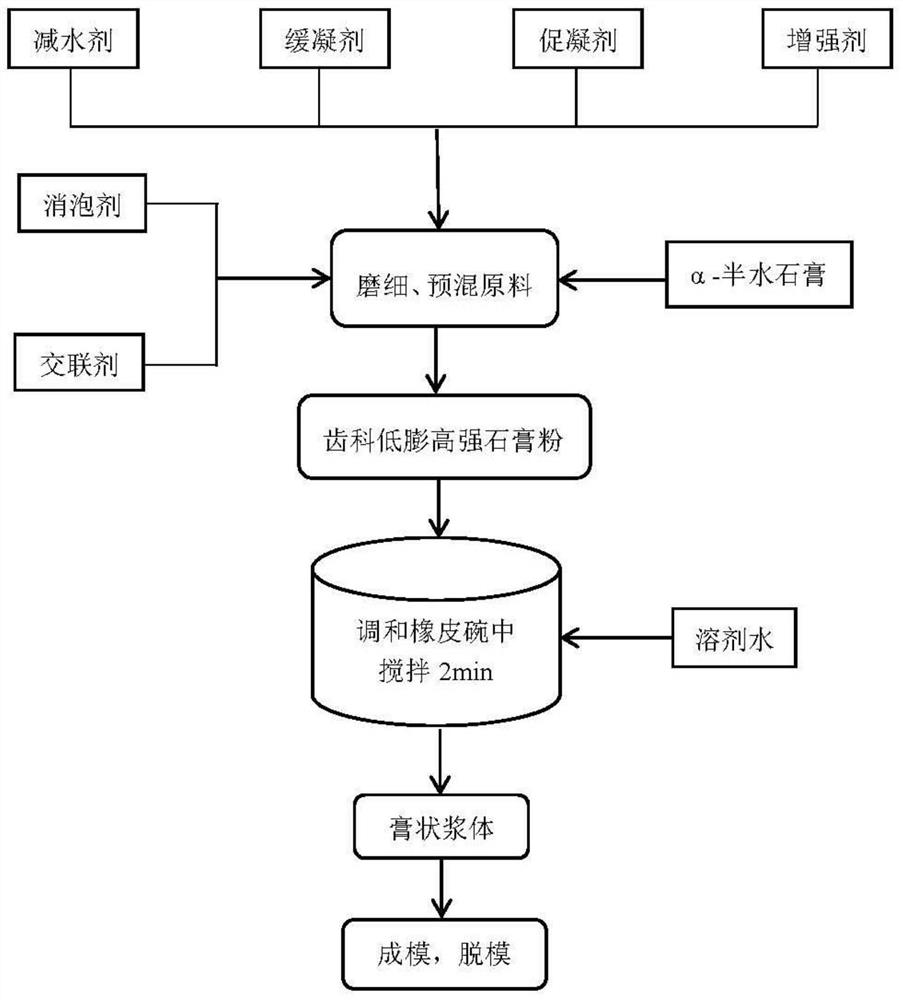

[0076] Another object of the present invention is to provide a method for preparing the low-expansion high-strength dental gypsum or gypsum composition, which specifically includes the following steps:

[0077] Step 1. Prepare hemihydrate gypsum powder.

[0078] The hemihydrate gypsum powder is α-high strength hemihydrate gypsum powder. The particle size of the hemihydrate gypsum powder is 70-130 mesh, preferably 85-115 mesh, more preferably 95-105 mesh.

[0079] Step 2, prepare each component, preferably grind separately.

[0080] The additives include one or more of water reducing agents, setting retarders, setting accelerators, reinforcing agents, crosslinking agents or defoamers.

[0081] The grinding method is manual grinding or mechanical grinding, preferably mechanical grinding.

[0082] After grinding, the particle size of the additive is 70-130 mesh, preferably 85-115 mesh, more preferably 95-105 mesh. The particle size of the additive is 70-130 mesh, preferably 8...

Embodiment 1

[0115] Various additives were placed in a tank mill and pulverized to 100 mesh. Weigh 3g AF-JFL-1, 0.2g JR, 6g aluminum stearate, 20g nano silicon dioxide, 1.5g borax, put the above additives in the mixer, and then weigh 50g of α-hemihydrate gypsum powder Add it into the mixer for mixing, mix for 60s, continue to add 100g of α-hemihydrate gypsum powder to the mixer, mix for 60s, then add 300g of α-hemihydrate gypsum powder, mix for 60s, and finally add 550g The α-hemihydrate gypsum was mixed for 60s to obtain a low-expansion high-strength dental gypsum composition.

[0116] Weigh 2000g of the above-mentioned gypsum composition, add 460g of water, let it stand for 30s, and then manually stir for 60-90s to obtain a slurry for measuring the expansion degree, initial and final setting time, linear expansion rate, and flexural resistance after 2h. compressive strength and wet compressive strength.

Embodiment 2

[0118] Various additives were placed in a tank mill and pulverized to 100 mesh. Weigh 3g AF-JFL-1, 0.4g SG, 9g aluminum stearate, 20g nano silicon dioxide, 1.5g borax, 2g emulsified silicone oil, put the above additives in the mixer, and then weigh 50g of α- Add hemihydrate gypsum powder into the mixer and mix with various additives for about 60s, continue to add 100g of α-hemihydrate gypsum powder into the mixer, mix for 60s, then add 300g of α-hemihydrate gypsum powder, Mix for 60 seconds, and finally add 550 g of α-hemihydrate gypsum and mix for 60 seconds to obtain a low-expansion high-strength dental gypsum composition.

[0119] Weigh 2000g of the above-mentioned gypsum composition, add 460g of water, let it stand for 30s, and then manually stir for 60-90s to obtain a slurry for measuring the expansion degree, initial and final setting time, linear expansion rate, and flexural resistance after 2h. compressive strength and wet compressive strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com