A pcb board clamp-free continuous drilling equipment

A technology for PCB boards and drilling equipment, applied in drilling/drilling equipment, boring/drilling, metal processing equipment, etc., can solve problems such as low automation, unfavorable large-scale production needs of enterprises, and inability to achieve time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, the technical solution of the present invention will be described in detail through specific examples.

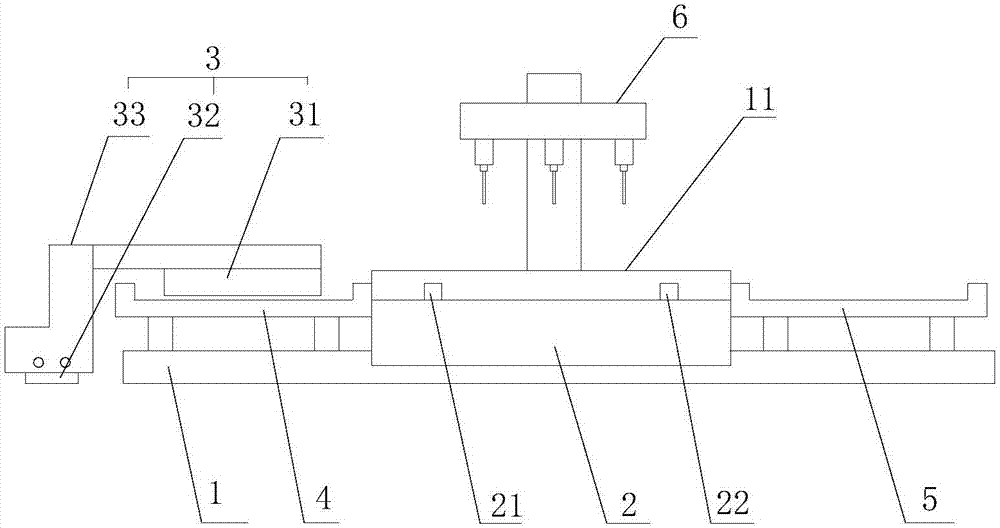

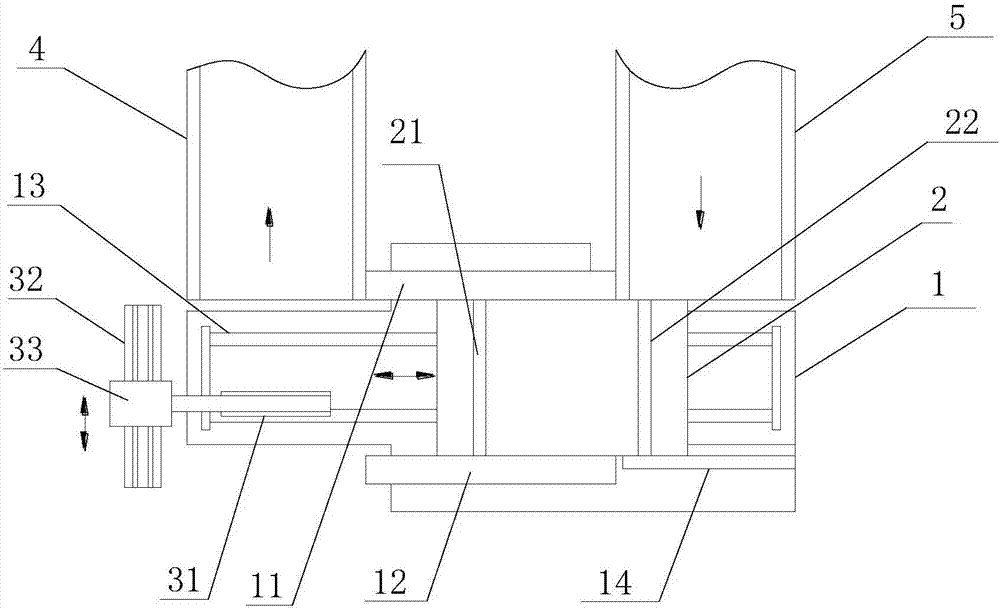

[0030] Such as Figure 1-2 Show, figure 1 It is a structural schematic diagram of a kind of PCB board exempt from clamping continuous drilling equipment proposed by the present invention; figure 2 It is a top view of a continuous drilling equipment without clamping for PCB board proposed by the present invention.

[0031] refer to Figure 1-2 , a PCB board clamping-free continuous drilling equipment proposed in the embodiment of the present invention, including: a base 1, a sliding table 2, a pushing device 3, a first conveying device 4, a second conveying device 5, and a drilling device 6 and drive means, wherein;

[0032] The base 1 is arranged horizontally. The base 1 is provided with a first block 11 and a second block 12 arranged oppositely. On the base 1 and between the first block 11 and the second block 12, there is a linear extension The guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com