Movement control method for electronic spiral guide rail of gear shaper

A spiral guide rail and motion control technology, applied in the direction of electrical program control, program control, digital control, etc., can solve the problems that the control method of electronic spiral guide rail is not mature enough, so as to improve the processing efficiency and quality, the control method is simple and reliable, and the The effect of execution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

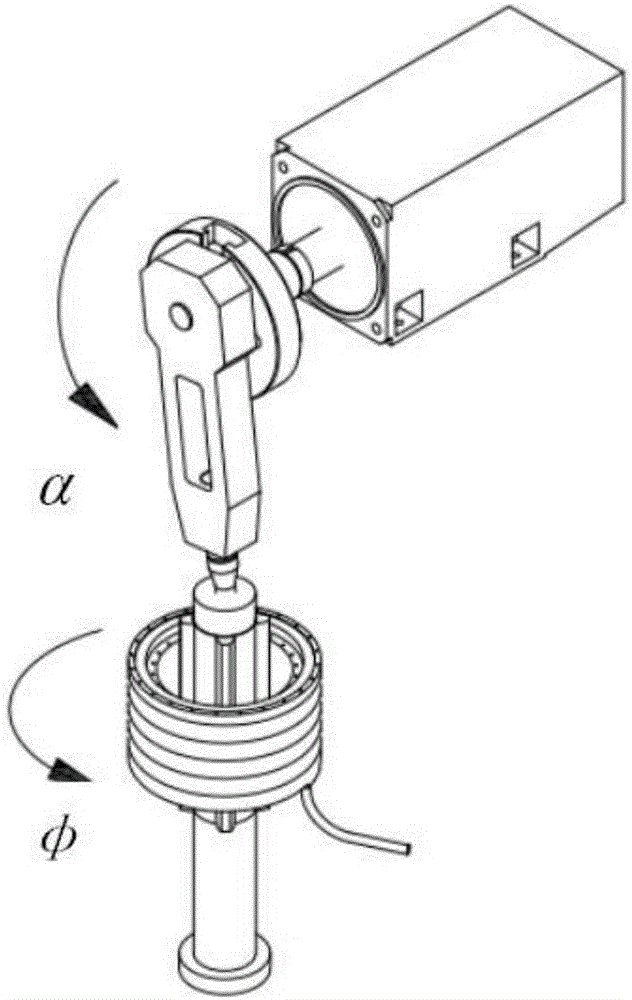

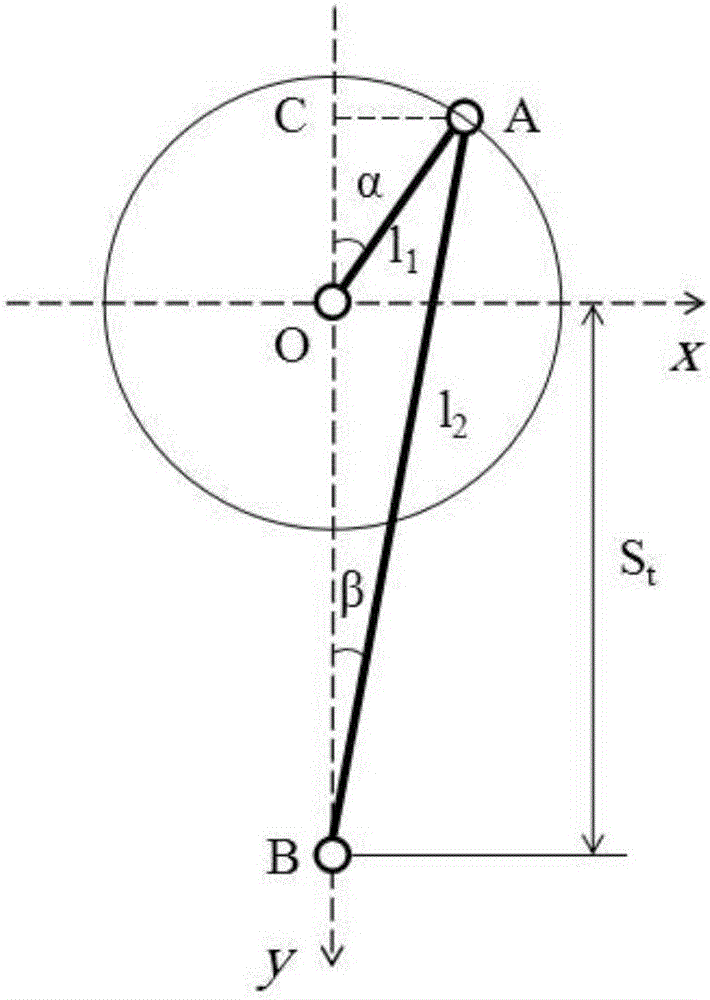

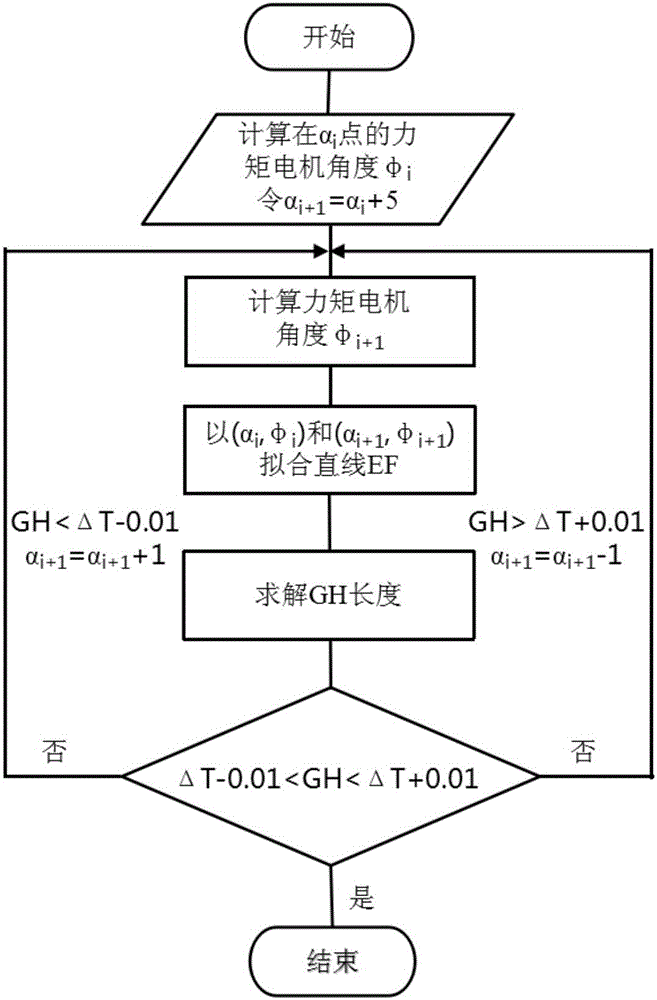

[0020] Such as Figure 1-2 As shown, a motion control method of the electronic spiral guide rail of the gear shaping machine realizes the correct control of the electronic spiral guide rail and can calculate the efficient operation program of the electronic spiral guide rail.

[0021] The crank angle of the gear shaping machine is the rotation angle a of the main motor, and the angle of the helical motion of the cutter shaft of the gear shaping machine is the rotation angle φ of the torque motor. The rotation angle a of the main motor and the rotation angle φ of the torque motor have a real-time nonlinear relationship. f=F(a) means; the rotation angle a of the main motor is the active value, and its value is a discrete non-arithmetic sequence, and the rotation angle φ of the torque motor is the following value. By establishing the rotation angle and torque of the main motor in the numerical control system The periodic curve table of the motor rotation angle is used to control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com