Intelligent flexible manipulator

A manipulator and flexible technology, applied in the field of manipulators, can solve the problems of difficulty in grasping fragile objects, lack of online perception of the size and position of fragile objects, and flexible grasping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

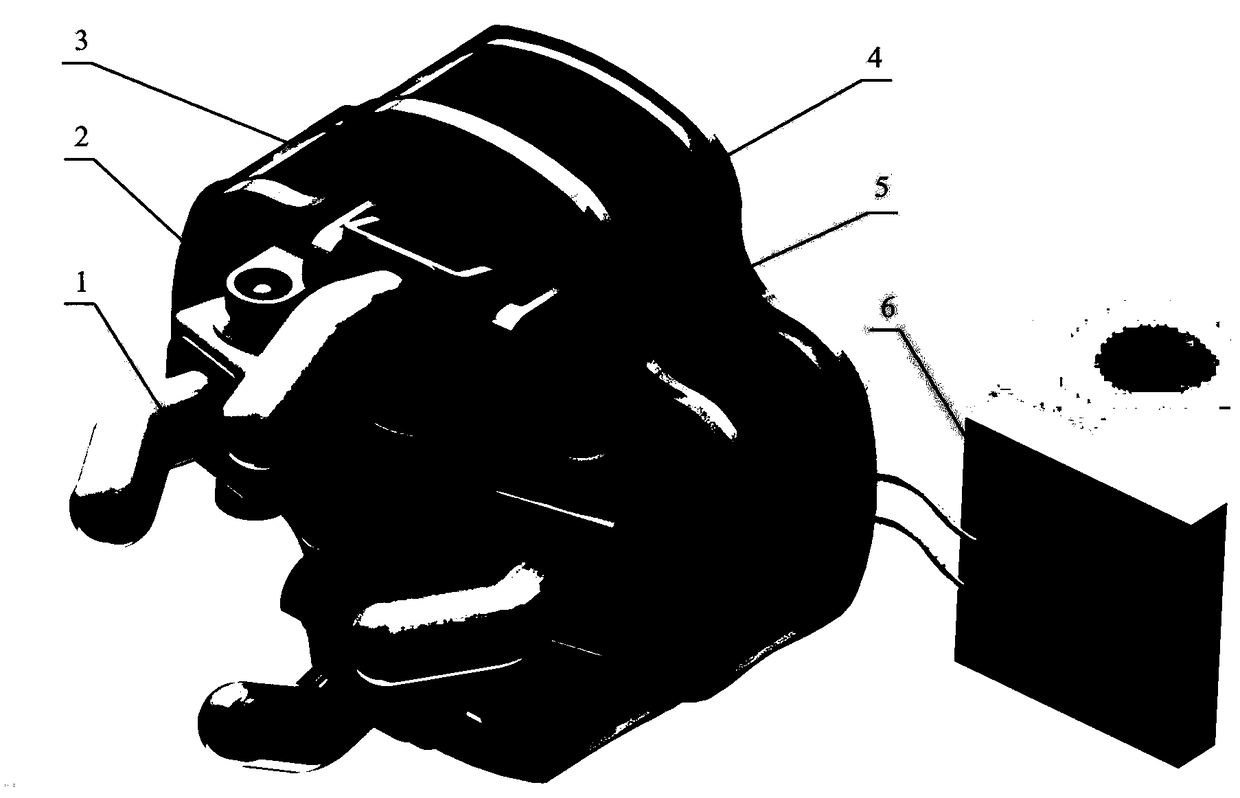

[0026] see figure 1 , this patent provides an intelligent flexible operating hand, including four flexible tactile fingers 1, an upper base plate 2, a base middle base plate 3, a base lower plate 4, four air pumps 5 and a main control module 6 The flexible tactile finger 1 is connected to the lower base 4 of the base through the upper base 2 of the base; the upper base 2 of the base and the lower base 4 of the base are connected and fixed to the middle base 3 of the base ; The air pump 5 is connected to the flexible tactile finger 1 and fixed on the bottom plate 4 of the base for realizing the air pressure driving of the flexible tactile finger 1 to control the stiffness of the flexible tactile finger 1 ; The air pump 5 and the flexible tactile finger 1 are respectively connected to the main control module 6 under control.

Embodiment 2

[0028] This embodiment is basically the same as Embodiment 1, especially in that:

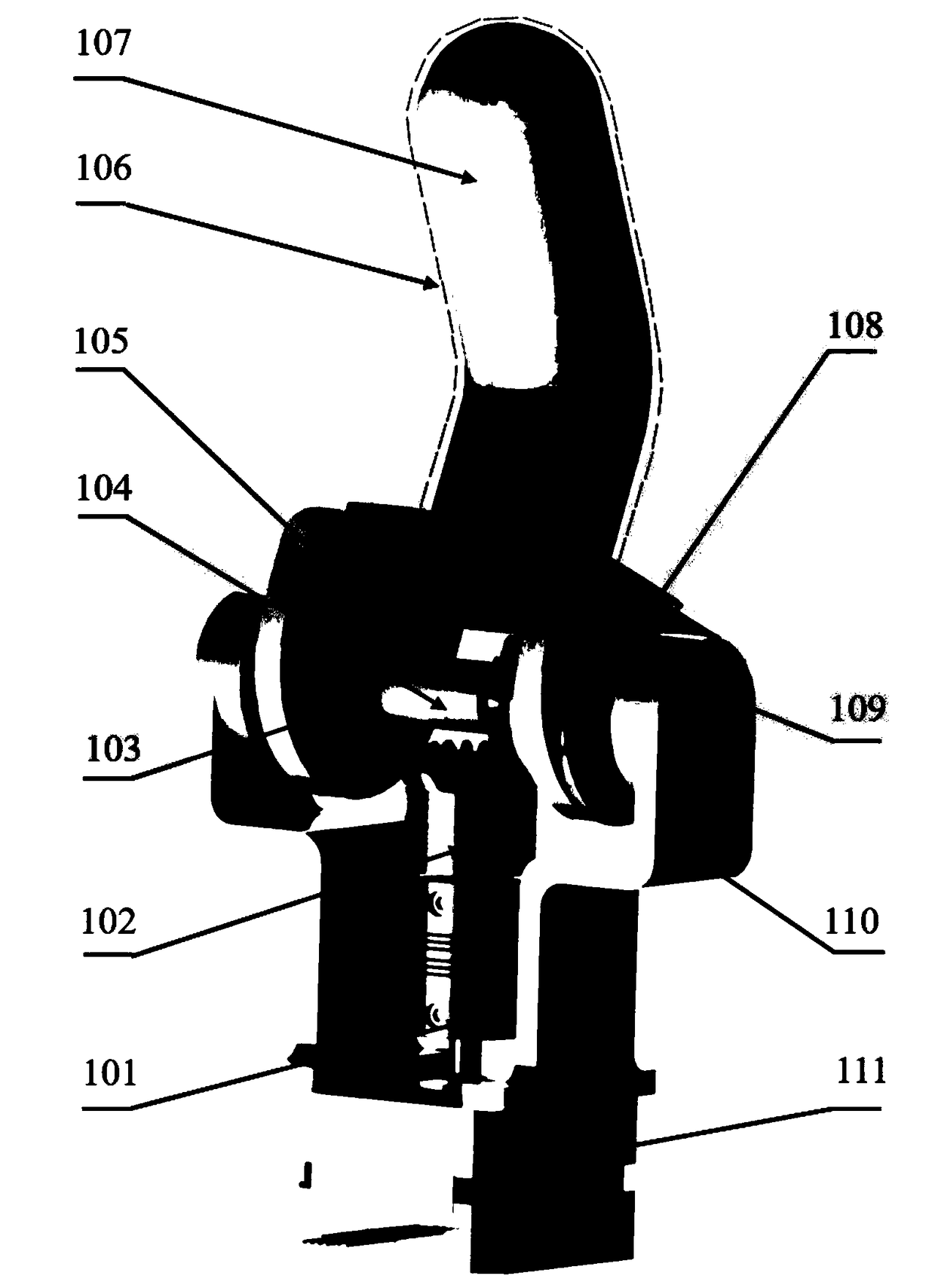

[0029] see figure 2 , a flexible tactile finger described in this patent adopts a hollow thin-wall flexible structure, including a coupling 101, a bevel gear set 102, a rotating shaft fixing flange 103, a rotating shaft 104, a flexible tactile finger base Seat 105, a conductive silicone sensor 106, a flexible touch finger 107, a bevel gear fixed flange 108, two deep groove ball bearings 109, two bearing blocks 110 and a stepping motor 111; the conductive silicone sensor 106 Attached to the surface of the flexible tactile finger 107, it is used to realize the micro-contact force and the position perception of the contact point; the flexible hand 107 is connected with the flexible tactile finger base 105 and is made of flexible material; the The vertical direction bevel gear 102 is connected with the stepper motor 111 through the coupling 101; The tactile finger base 105 is connected; the rota...

Embodiment 3

[0031] This embodiment is basically the same as Embodiment 1, especially in that:

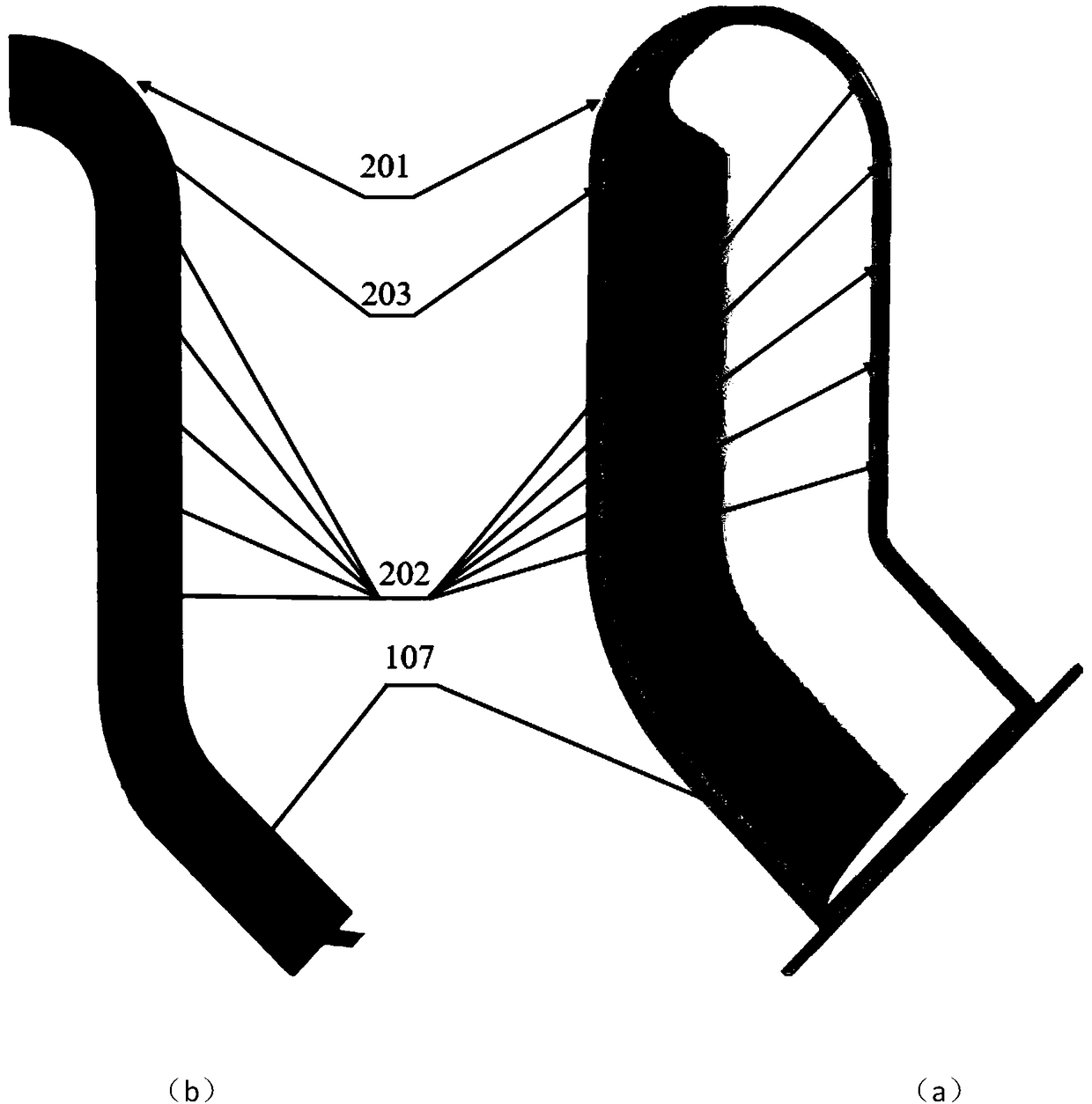

[0032] see image 3 The conductive silicone sensor 106 described in this patent includes a plurality of conductive silicone fillers 202, a silicone base 203, and a finger covering film 204; the silicone base 203 is attached to the surface of the flexible tactile finger 107; Conductive silicone filler 202 is filled in the silicone base 203 to form a conductive silicone sensor array; the finger outer film 204 covers the silicone base 203 to protect the internal structure; by detecting the resistance of the conductive silicone filler 202 Press characteristics to realize tactile detection of contact point position and micro-contact force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com