Machining device for aluminum profiles of sliding doors and windows

A technology for sliding doors and windows and processing equipment, applied in metal processing equipment, metal processing, metal sawing equipment, etc., can solve the problems of increased production costs, long production lines, and large floor space, so as to increase utilization and reduce production The effect of cost reduction and labor intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

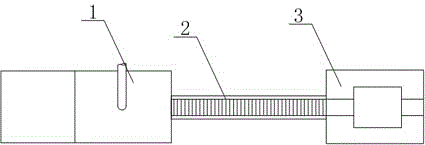

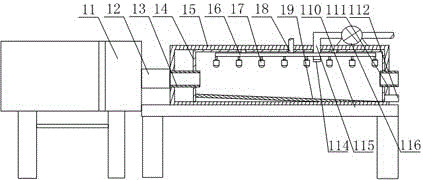

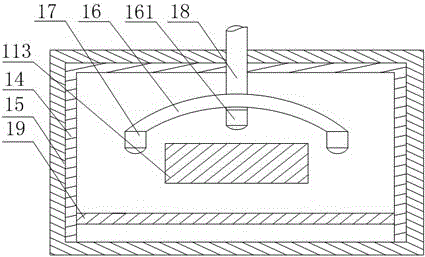

[0027] Such as Figure 1~Figure 5 As shown, this embodiment includes an extruder 1 and a cutting machine 3. The extruder 1 is connected to the cutting machine 3 through a roller conveyor belt 2, and the extruder 1 includes an extruder body 11 and is mounted on a bracket 110 The water-cooled box 15 is provided with a coaxial feed pipe 13 and a discharge pipe 111 at both ends of the water-cooled box 15 respectively. The discharge cylinder 12 of the extruded body 11 is connected to the feed pipe 13, and the water-cooled A heat insulation cavity 14 is installed in the box 15, and the feed pipe 13 and the discharge pipe 111 respectively penetrate the two side walls of the heat insulation cavity 14. In the heat insulation cavity 14, a downwardly curved arc branch pipe 16 is provided. The branch pipe 16 covers the area between the feed pipe 13 and the discharge pipe 111. A plurality of side nozzles 17 are respectively installed at the ends of the two bending sections of the branch pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com