Grinding technology for joint bearing inner rings

A technology for spherical plain bearings and inner rings, which is applied in the field of bearing processing, can solve problems such as poor appearance quality, unstable dimensional control, and difficulty in grinding the inner rings of spherical plain bearings, and achieve the effects of convenient processing, short processing cycle and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

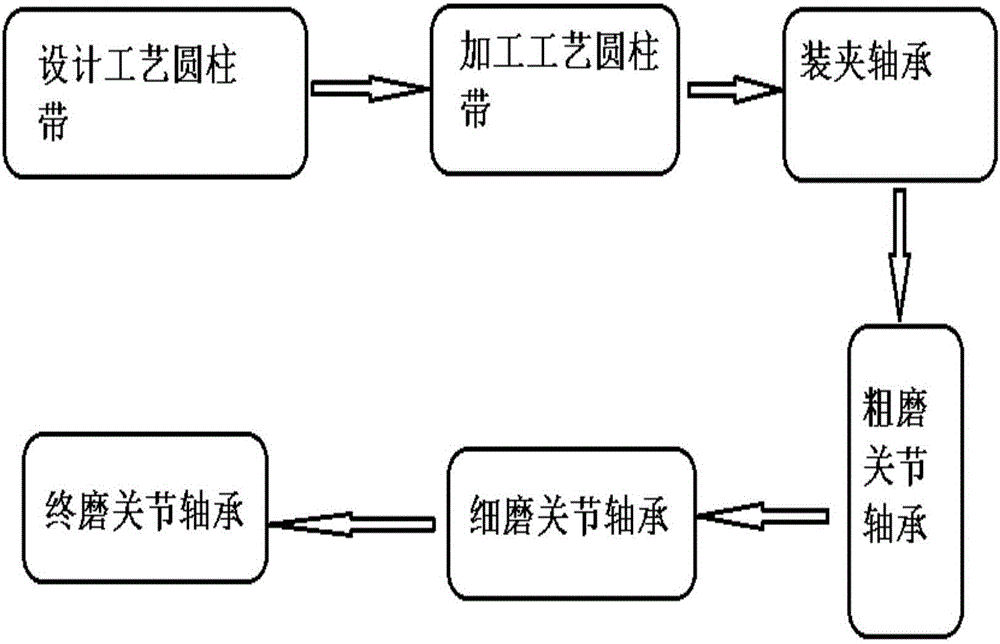

Method used

Image

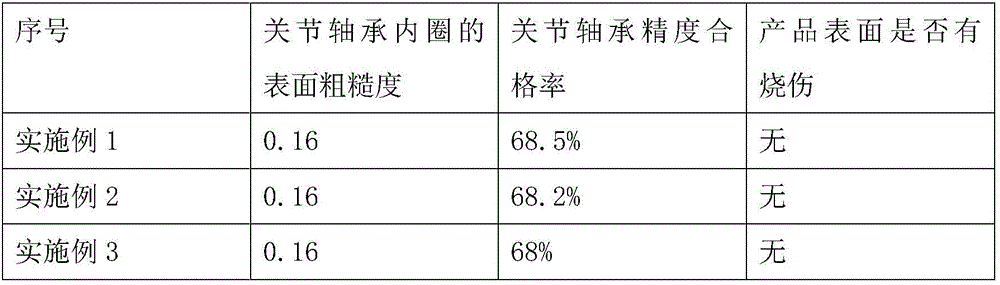

Examples

Embodiment 1

[0021] In this embodiment, a grinding process for the inner ring of a spherical plain bearing is carried out according to the following steps:

[0022] (1) Design a process cylinder belt that can provide accurate positioning;

[0023] (2), process a process cylinder band with a centerless grinder;

[0024] (3) Distribute the processed cylindrical belt on both sides of the oil groove, clamp the joint bearing on the grinding machine, and change the original point contact to line contact with the technical cylindrical belt;

[0025] (4), using a grinding wheel to roughly grind the clamped spherical plain bearing obtained in step (3), to obtain a rough-ground spherical plain bearing; the surface roughness of the inner ring of the rough-ground spherical plain bearing is Ra0.5 ;

[0026] (5), under the conditions that the grinding wheel speed is 6000r / min, the workpiece speed is 400r / min and the feed speed is 0.01mm / r, the joint bearing after the rough grinding obtained in step (4...

Embodiment 2

[0029] (1) Design a process cylinder belt that can provide accurate positioning;

[0030] (2), process a process cylinder band with a centerless grinder;

[0031] (3) Distribute the processed cylindrical belt on both sides of the oil groove, clamp the joint bearing on the grinding machine, and change the original point contact to line contact with the technical cylindrical belt;

[0032] (4), using a grinding wheel to roughly grind the clamped spherical plain bearing obtained in step (3), to obtain a rough-ground spherical plain bearing; the surface roughness of the inner ring of the rough-ground spherical plain bearing is Ra0.5 ;

[0033] (5), under the conditions that the grinding wheel speed is 6000r / min, the workpiece speed is 500r / min and the feed speed is 0.01mm / r, the joint bearing after the rough grinding obtained in step (4) is finely ground by using a grinding wheel to obtain A finely ground spherical plain bearing; the surface roughness of the inner ring of the fi...

Embodiment 3

[0036] (1) Design a process cylinder belt that can provide accurate positioning;

[0037] (2), process a process cylinder band with a centerless grinder;

[0038] (3) Distribute the processed cylindrical belt on both sides of the oil groove, clamp the joint bearing on the grinding machine, and change the original point contact to line contact with the technical cylindrical belt;

[0039] (4), using a grinding wheel to roughly grind the clamped spherical plain bearing obtained in step (3), to obtain a rough-ground spherical plain bearing; the surface roughness of the inner ring of the rough-ground spherical plain bearing is Ra0.5 ;

[0040] (5), under the conditions that the grinding wheel speed is 6000r / min, the workpiece speed is 560r / min and the feed speed is 0.01mm / r, the joint bearing after the rough grinding obtained in step (4) is finely ground by using a grinding wheel to obtain A finely ground spherical plain bearing; the surface roughness of the inner ring of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com