Straw package disassembling device and method

A technology for breaking up straws and bales, which is applied in the field of agricultural machinery, can solve the problems of relying on labor for unpacking and removing nets, consuming man-hours, and low efficiency, and achieves the effect of solving the bottleneck of large-scale processing, saving manpower and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

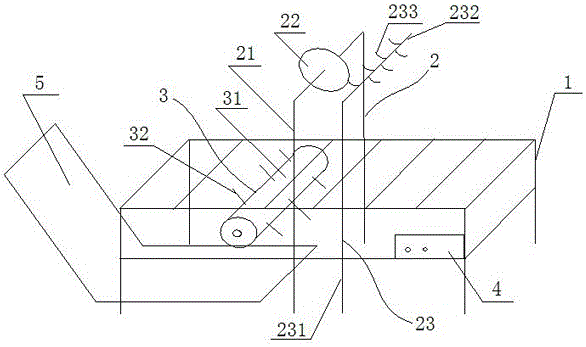

[0015] A straw bale dismantling method, which is automatically completed by a straw bale dismantling device. The straw bale dismantling device at least includes a conveying platform 1, an omentum removal mechanism 2 installed on the conveying platform, and a straw beating mechanism installed under the conveying platform. The crushing mechanism 3, and the electric control power mechanism 4 installed on the conveying platform body, the straw bag is put into the conveying platform 1, and is first transported to the omentum removal mechanism 2, and the electric control power mechanism 4 controls the omentum removal mechanism 2 to remove the omentum , and then the conveying platform 1 continues to transport the straw bales with the omentum removed to the straw crushing mechanism 3 to break up the straw bales.

[0016] Such as figure 1 As shown, the straw bale dismantling device further includes a transport mechanism 5, which is located below the straw crushing mechanism 3, and tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com