Precisely positioned aerial flexible switching conveying equipment

A conveying equipment and precise positioning technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of high equipment manufacturing cost and application cost, large space occupation, and complexity, so as to achieve safe and reliable performance and reduce occupation Space, the effect of reducing equipment manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

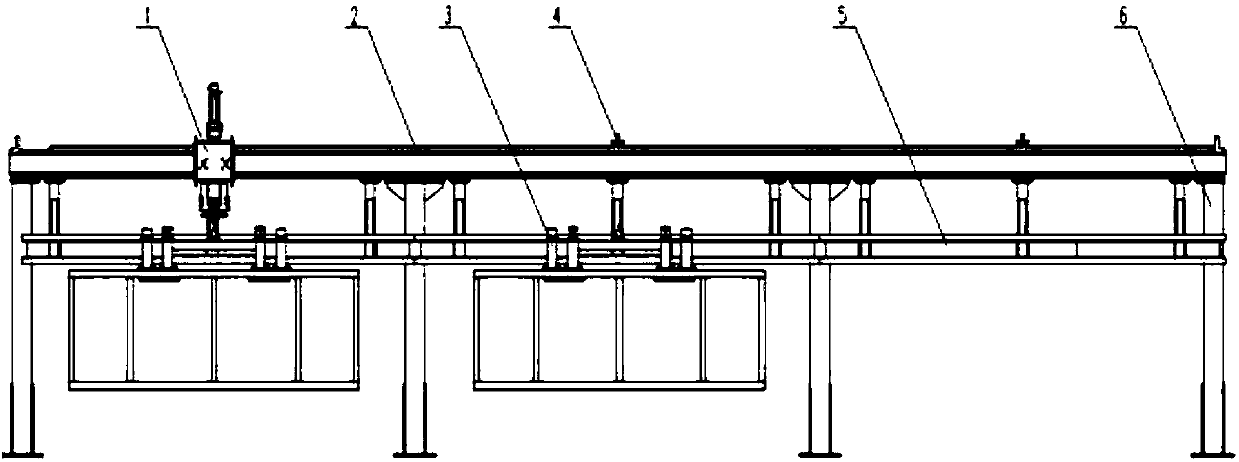

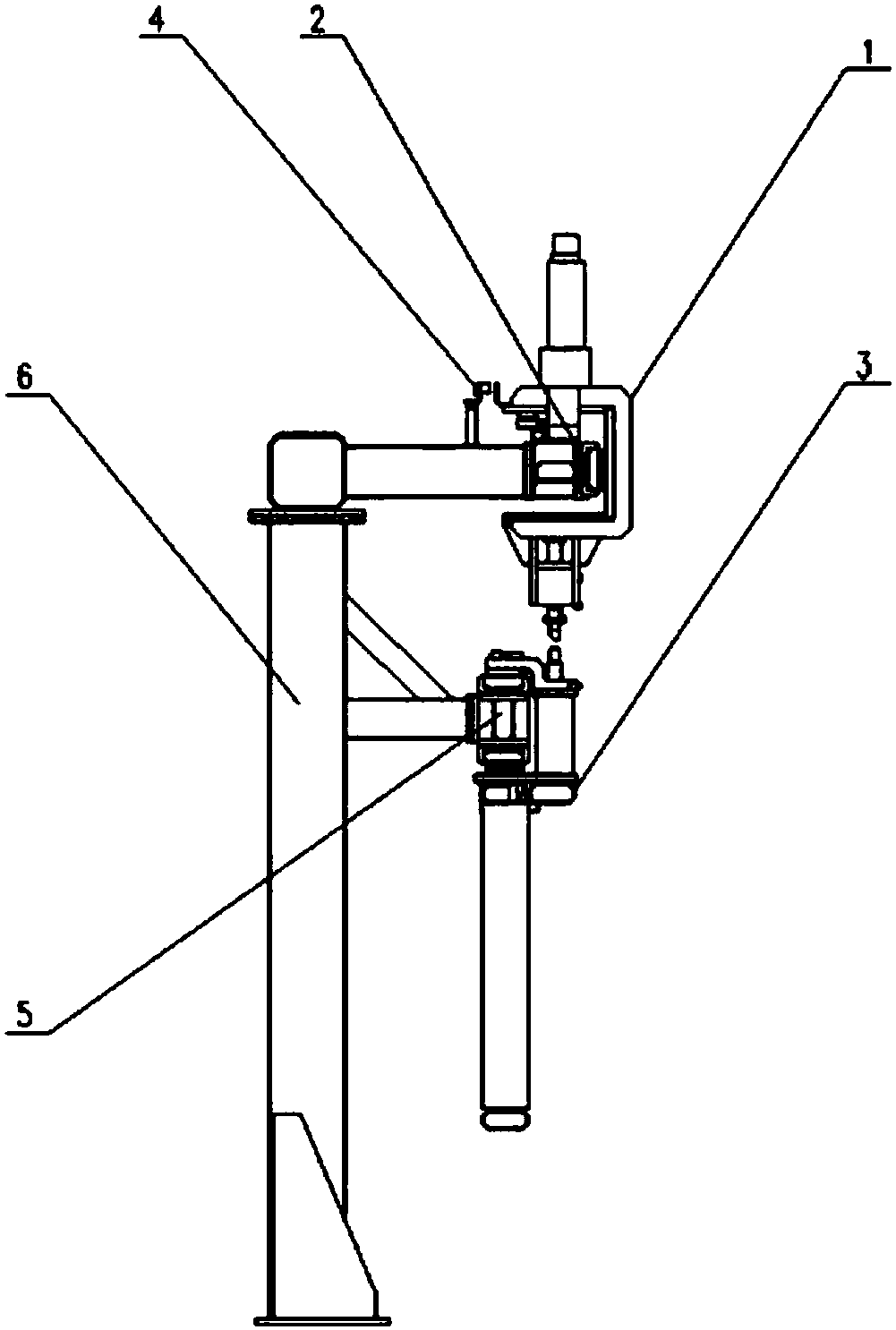

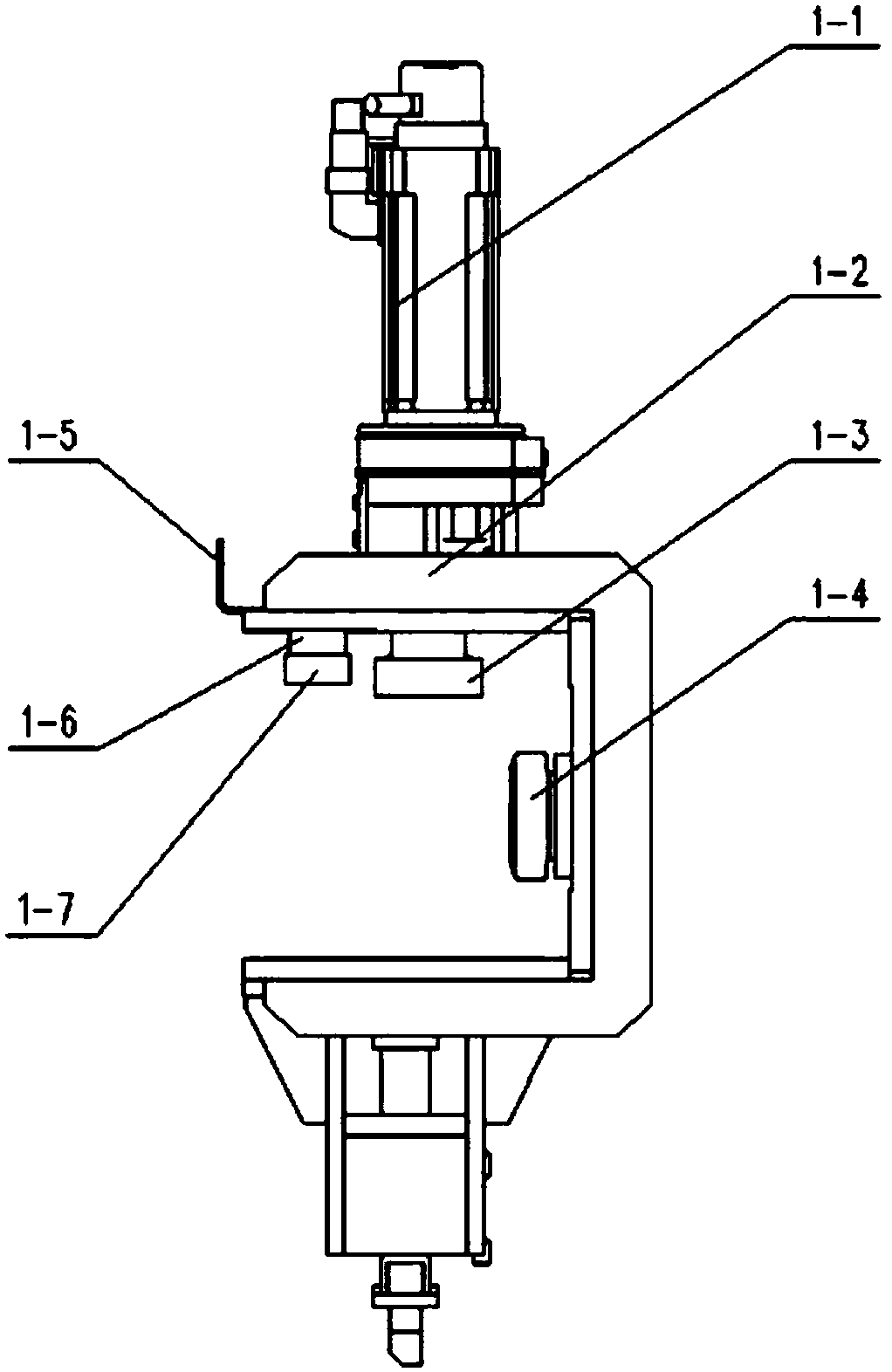

[0038] Such as Figure 1-Figure 17 As shown, a kind of precisely positioned aerial flexible switching conveying equipment is composed of a drive assembly 1, a drive rail assembly 2, a load trolley assembly 3, a switch assembly 4, a load rail assembly 5 and a main support assembly 6; The support assembly 6 is provided with a drive track assembly 2 and a load track assembly 5 in parallel on the upper and lower sides, the drive track assembly 2 is mounted on the drive assembly 1 for cooperating operation, and the load trolley assembly 3 is installed on the load track assembly 5 for cooperating operation; The main support assembly 6 is provided with a switch assembly 4 that cooperates with the drive motor 1-1 in the drive assembly 1; the switch assembly 4 plays a role in con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com