Automatic wire cutting-coiling-binding integrated machine and wire coiling device thereof

The technology of a winding device and an all-in-one machine is applied in the parts of the strapping machine, strapping materials, transportation and packaging, etc., which can solve the problems of high labor intensity, poor market competitiveness, and low degree of automation, and improve the fluency. , Improve the degree of automation, reduce the effect of process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

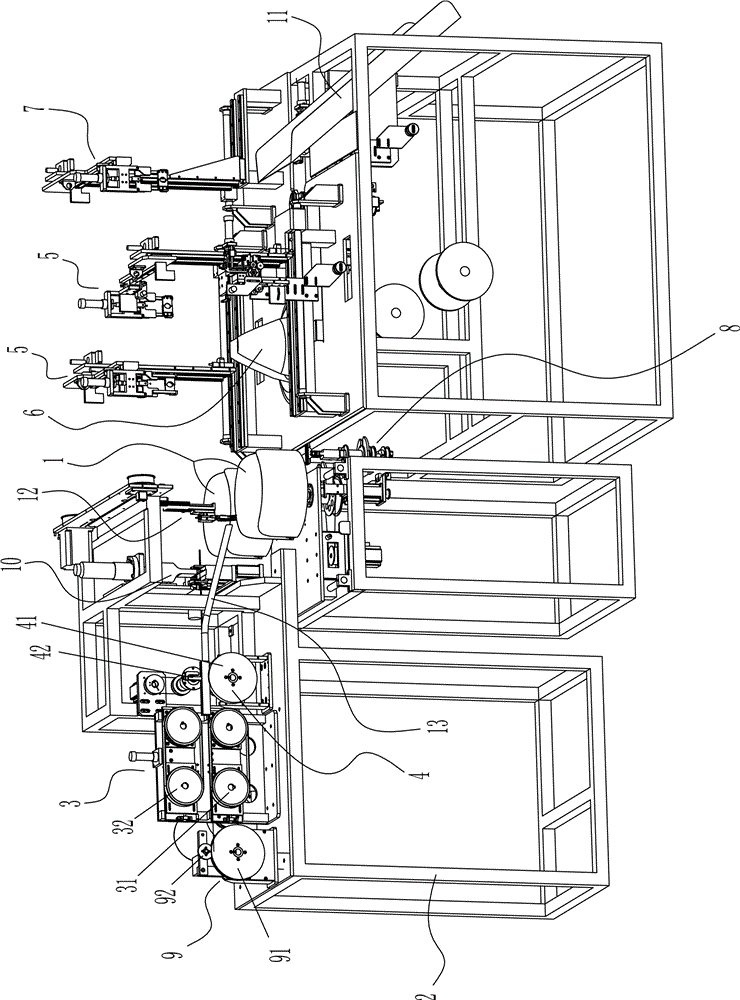

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

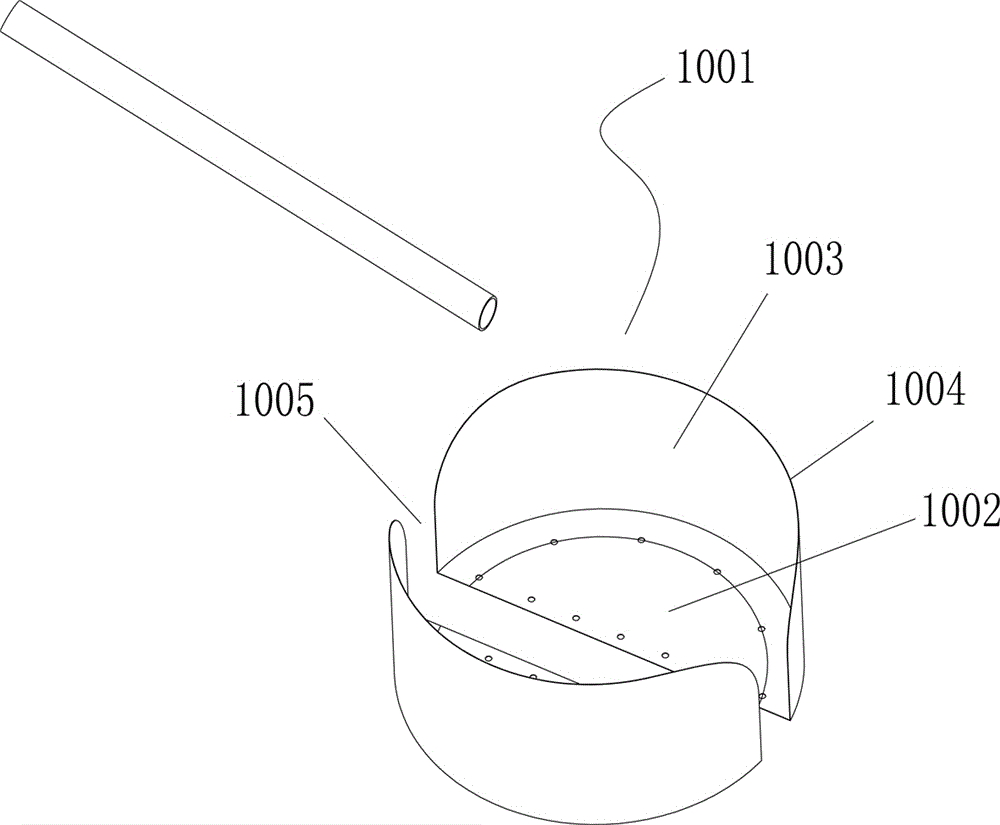

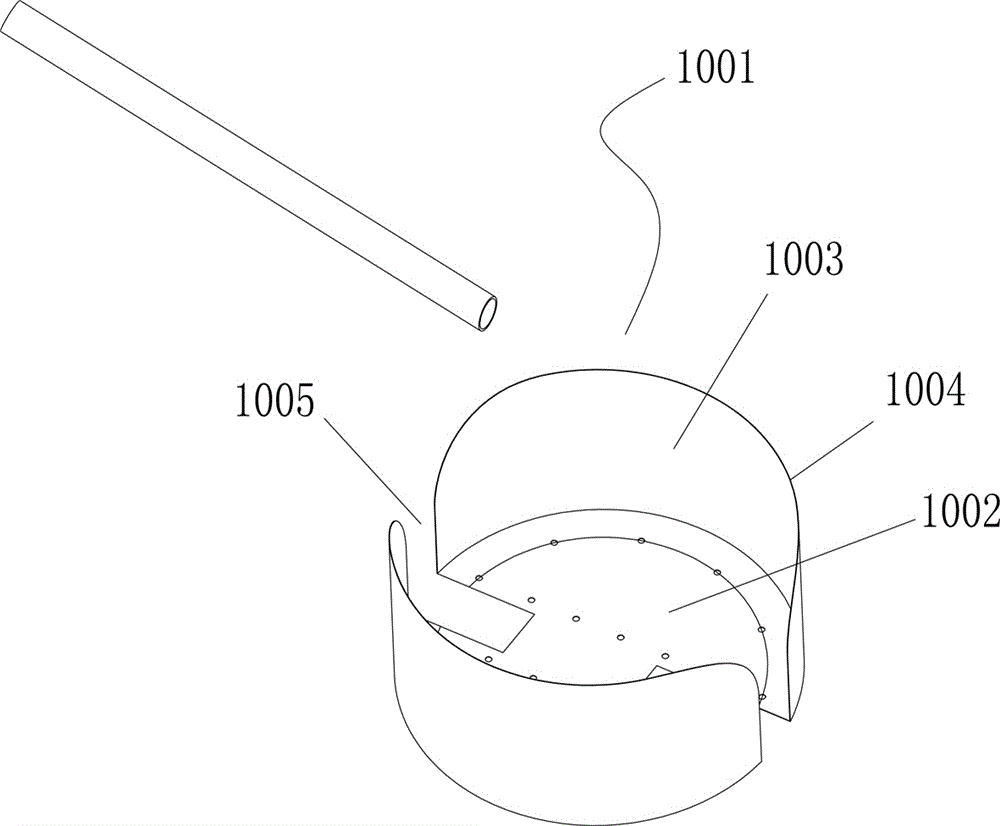

[0029] Such as figure 1 , 2 As shown, a winding device 1 includes a bobbin 1001. The bobbin 1001 is driven by a motor at the bottom to rotate itself. The bobbin 1001 includes a chassis 1002, and a side wall 1003 is erected on the edge of the chassis 1002. The side wall 1003 encloses a circular inner cavity; the side wall 1003 of the bobbin 1001 is provided with an avoidance gap 1005 for the wire to enter, and the wire is extruded from the extruder and close to the inner wall of the bobbin 1001 along the The steering is coiled with the bobbin 1001 .

[0030] Specifically, the bobbin 1001 may be composed of at least two bobbin assemblies 1004, and the connection between the bobbin assemblies 1004 may be partial splicing (such as figure 2 ) or spaced splicing (eg figure 1 ), the avoidance gap 1005 is provided between adjacent bobbin assemblies 1004 . The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com