A kind of rubber coated fabric based on nano microsphere and polymer and preparation method thereof

A technology of nano-microspheres and rubber coatings, which is applied in the direction of textiles and papermaking, etc. It can solve the problems of being easily damaged, the use of fabrics is limited, and the combination of nano-sphere films is not tight, so as to achieve a fixed structure, tight connection, stable viscosity and humidity , the effect of tight combination fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

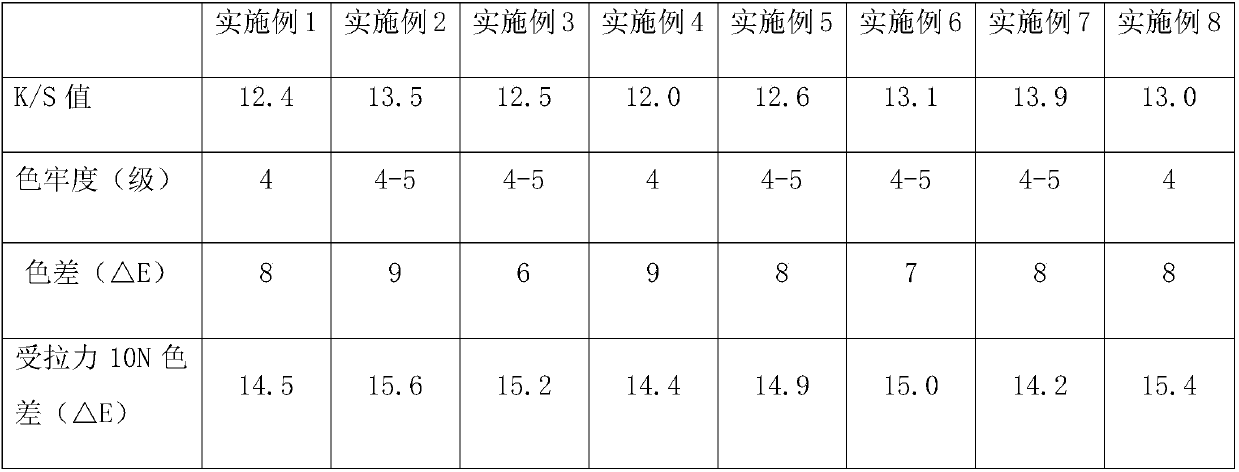

Examples

Embodiment 1

[0028] (1) Polyurethane elastic fiber is used as raw material, plain weave structure is used as the fabric structure, and the base fabric is formed by weaving, and the base fabric is treated with 250W power plasma at low temperature for 30s in an air atmosphere to obtain a pretreated base fabric.

[0029] (2) In parts by weight, add 30 parts of polyvinyl alcohol, 20 parts of polyacrylic acid, 10 parts of attapulgite, 5 parts of silicone rubber and 8 parts of glycerin into 40 parts of deionized water, and stir at high speed to obtain polymer, and then 15 parts of nano polystyrene acrylic microspheres with a particle diameter of 20nm are poured into the polymer, ground, pumped, and then 5 parts of ammonium persulfate crosslinking agent are added, mixed and ground to form a particle diameter of 200 mesh coating mix.

[0030] (3) Coating the coating mixture on the upper surface of the pretreated base cloth, wrapping the upper surface of the coating mixture and the lower surface of...

Embodiment 2

[0032] (1) PTT elastic fiber is used as raw material, plain weave structure is used as the fabric structure, and the base fabric is formed by weaving, and the base fabric is treated with 300W power plasma at low temperature for 50s in an air atmosphere to obtain a pretreated base fabric.

[0033] (2) In parts by weight, add 50 parts of polyvinyl alcohol, 40 parts of polyacrylic acid, 20 parts of attapulgite, 15 parts of silicone rubber and 16 parts of glycerin into 80 parts of deionized water, and stir at high speed to obtain Polymer, then 25 parts of nano polystyrene acrylic microspheres with a particle diameter of 100nm are poured into the polymer, ground, pumped, and then 10 parts of ammonium persulfate crosslinking agent are added, mixed and ground to form a particle diameter of 250 mesh coating mix.

[0034] (3) Coating the coating mixture on the upper surface of the pretreated base cloth, wrapping the upper surface of the coating mixture and the lower surface of the base...

Embodiment 3

[0036] (1) The PBT elastic fiber is used as raw material, the plain weave structure is used as the fabric structure, and the base fabric is formed by weaving, and the base fabric is treated with 280W power plasma at low temperature for 40s in an air atmosphere to obtain a pretreated base fabric.

[0037](2) In parts by weight, add 45 parts of polyvinyl alcohol, 25 parts of polyacrylic acid, 15 parts of attapulgite, 10 parts of silicone rubber and 12 parts of glycerin into 45 parts of deionized water, and stir at high speed to obtain Polymer, then 20 parts of nano polystyrene acrylic microspheres with a particle diameter of 80nm are poured into the polymer, ground, pumped, and then 7 parts of ammonium persulfate crosslinking agent are added, mixed and ground to form a particle diameter of 220 mesh coating mix.

[0038] (3) Coating the coating mixture on the upper surface of the pretreated base cloth, wrapping the upper surface of the coating mixture and the lower surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com