A method of oil production using coiled tubing to inject air into horizontal wells

A technology of coiled tubing and horizontal wells, which is applied in the field of air flooding oil production in oilfields, can solve the problems of unbalanced swept volume, difficulty in controlling the direction of gas, and low utilization rate of the horizontal section, and achieve balanced swept volume in the horizontal section, easy control of the direction of gas, The effect of improving formation connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

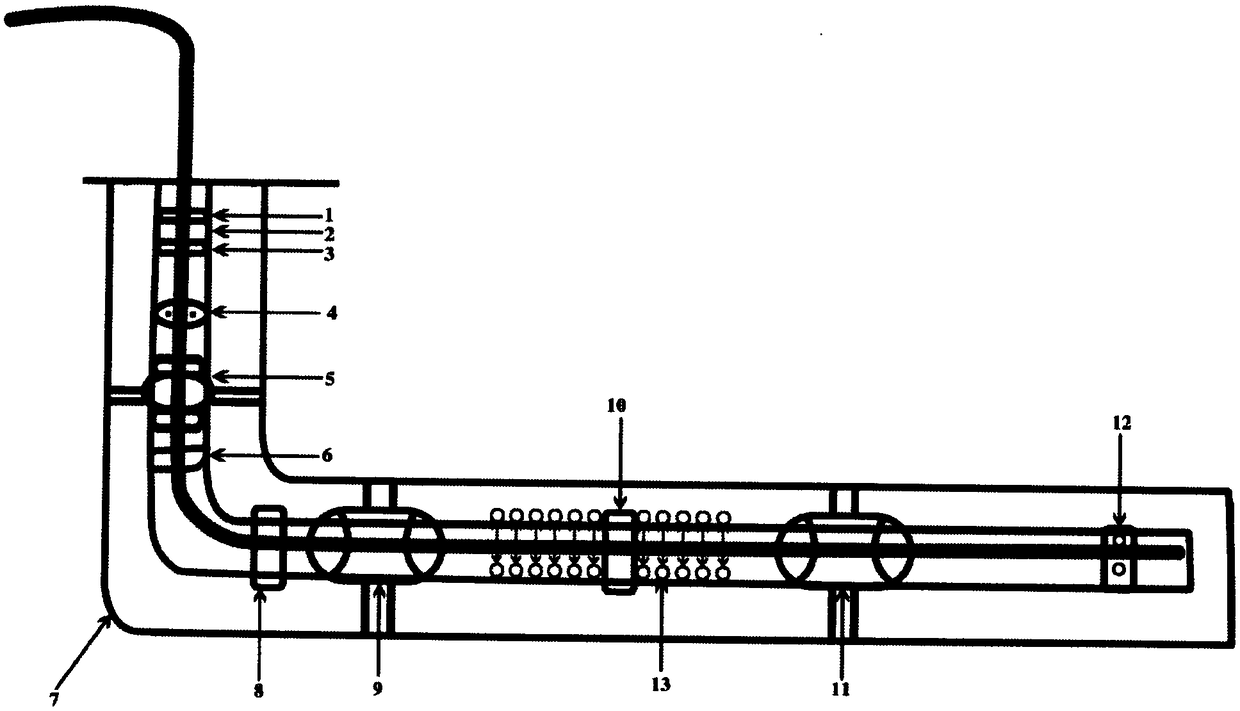

[0032] The oil recovery method of injecting air into a horizontal well by coiled tubing comprises the following steps:

[0033] 1. Determine the distribution of oil reservoirs in the formation, including the location of dead oil areas, areas that are difficult to reach during normal displacement, etc., and determine the specific location of crude oil that is difficult to produce in the horizontal section.

[0034] 2. After completion of high-pressure gas injection, coiled tubing is used to carry out segmental perforation at the position dismantled in step 1. The coiled tubing can be extended and retracted downhole to carry out supplementary perforation in different isolation sections, and the continuous drilling can be adjusted as needed. The running depth of pipe and perforating gun.

[0035] 3. After step 2 is completed, the gas injection part of the coiled tubing is lowered into the position to be injected. Firstly, the carbon dioxide injection system is used to inject 0.15...

Embodiment 2

[0039] Compared with Example 1, the difference is that in step 3, the injection amount of carbon dioxide is 0.18PV, followed by injection of 0.14PV, 135°C hot water; in step 4, 0.12PV of high-concentration oxygen-enriched oxygen is injected with an oxygen content of 65%.

Embodiment 3

[0041] Compared with Example 1, the difference is that in step 3, the injection amount of carbon dioxide is 0.13PV, followed by injection of 0.12PV, 165°C hot water; in step 4, 0.18PV of high-concentration oxygen-enriched oxygen is injected with an oxygen content of 55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com