Force transferring connection structure of columnar component and platy component

A plate-shaped member and connecting structure technology, applied in the direction of transmission box, transmission device, transmission device parts, etc., can solve the problems of difficult to ensure tolerance, troublesome processing, increase structure size, etc., and achieve easy installation, adjustment and disassembly, and small installation space. The effect of flexible matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

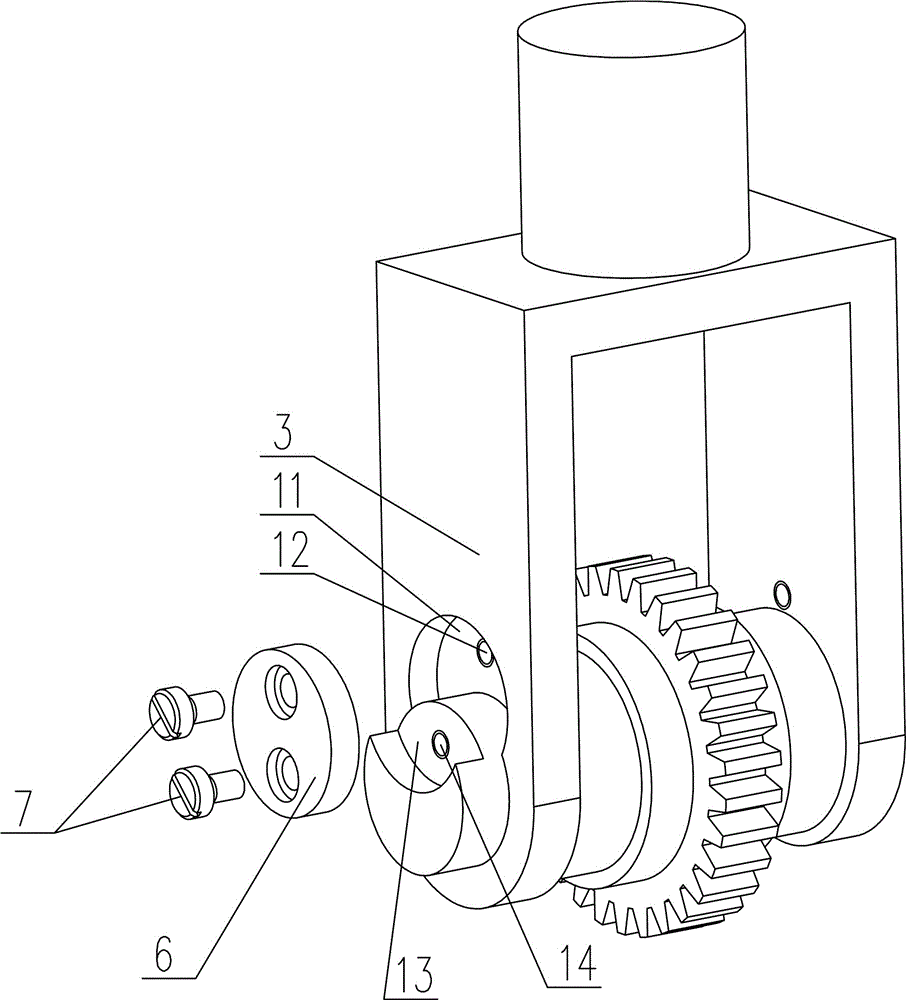

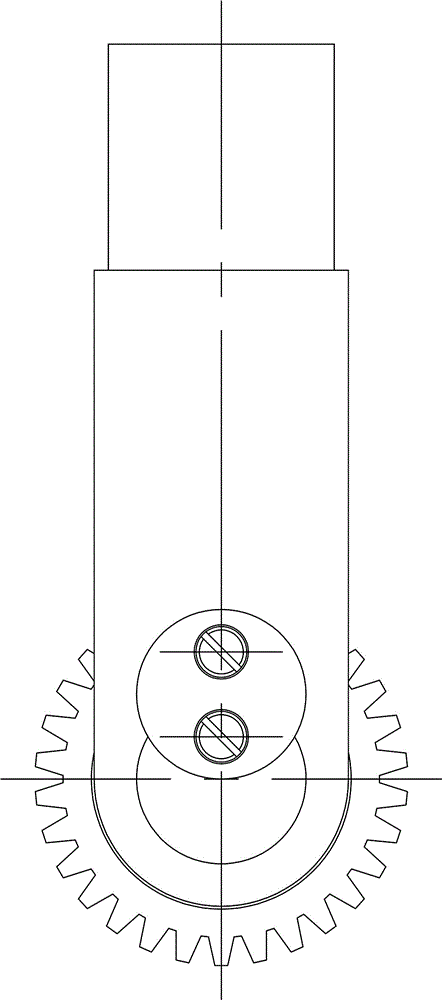

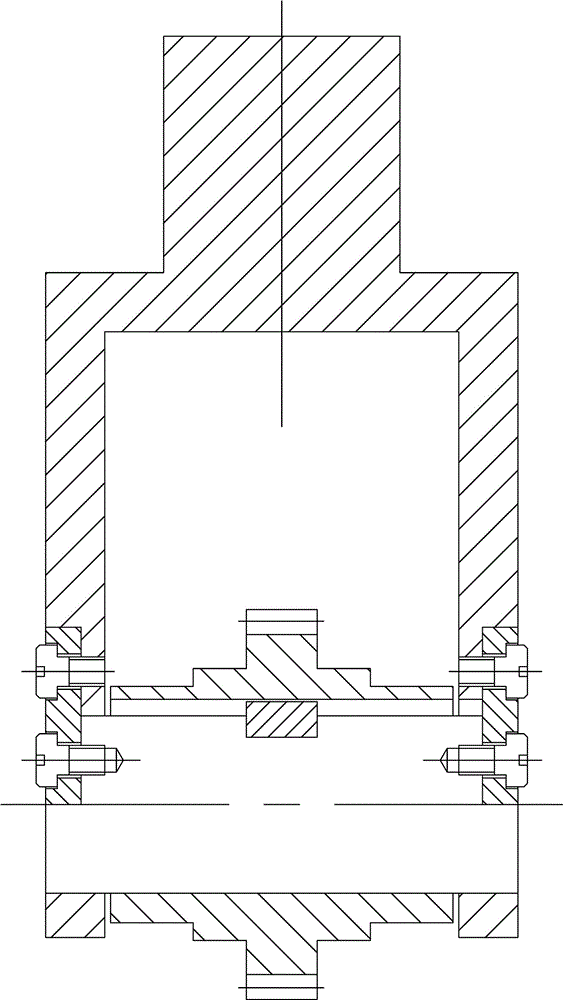

[0033] Such as Figure 1~3 Among them, a force transmission connection structure between a columnar and a plate-shaped member, the plate-shaped member is provided with a first sinking platform 11, the columnar member is provided with a second sinking platform 13, the first sinking platform 11 and the second sinking platform The first fixing hole 12 and the second fixing hole 14 are respectively arranged on the groove platform 13, and the first sinking groove platform 11 and the second sinking groove platform 13 form a blind hole whose cross section is circular, and the inner wall of the blind hole is in line with the circular shape. The outer wall of the key 6 forms a fit; in a preferred solution, the circular key 6 is an interference fit with the blind hole formed by the first sinker platform 11 and the second sinker platform 13 .

[0034] The circular key 6 is arranged in the first sinking platform 11 and the second sinking platform 13, and the circular key 6 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com