Check valve capable of analyzing liquid supply condition of oil well and method for analyzing liquid supply condition of oil well

A single-flow valve and oil well technology, which is applied in the direction of wellbore/well components, valve devices, earthwork drilling and production, etc., can solve the problems of not being able to reflect the change of oil well fluid supply in real time, and achieve automatic diagnosis, simple on-site installation, and acquisition The effect of high data accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

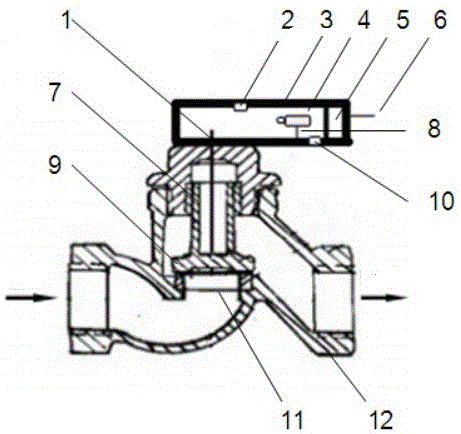

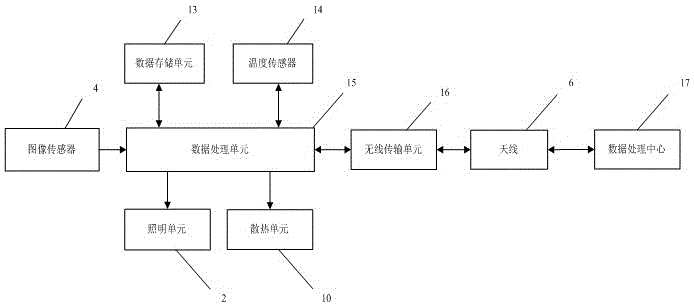

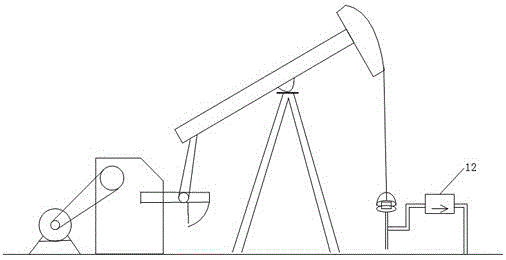

[0032] In order to be able to clearly understand the working principle of the check valve, such as figure 1 with figure 2 As shown, a check valve that can analyze the liquid supply of oil wells mainly includes an input end, an output end, a valve body 12, a valve core 9, a sealing seat 11, and a spring 7. The liquid can only flow from the input end to the valve body 12 Since the pressure at the input end is greater than the pressure at the output end, under the action of the pressure, the spring 7 is compressed, so that the valve core 9 moves up with the spring 7 and separates from the sealing seat 11, and the inflowing liquid flows out from the output end; When there is no liquid inflow, due to the action of the spring 7, the valve core 9 is in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com