Method and system for generating electrowetting drive waveform based on equal power

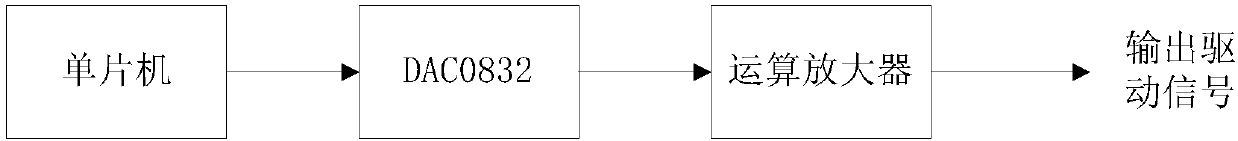

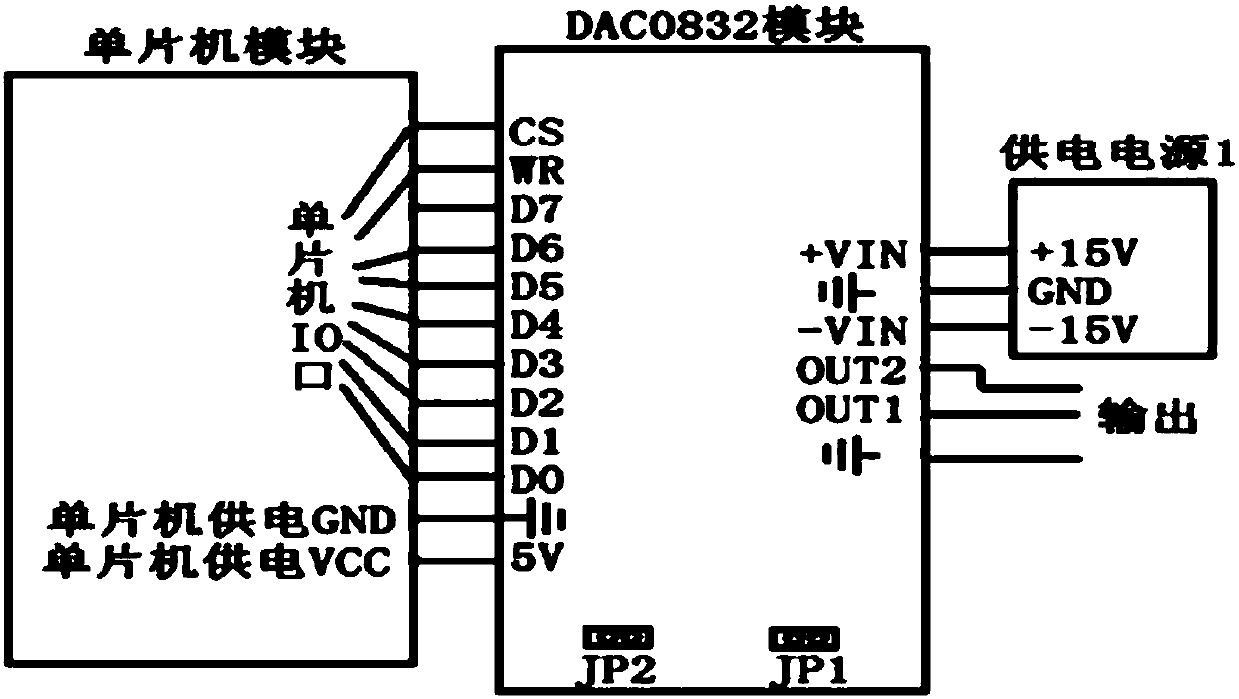

A driving waveform and electrowetting technology, applied in the field of electrowetting, can solve the problems affecting the service life of electrowetting devices, damage, high driving power, etc., and achieve the effect of avoiding display brightness reduction, preventing splitting, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

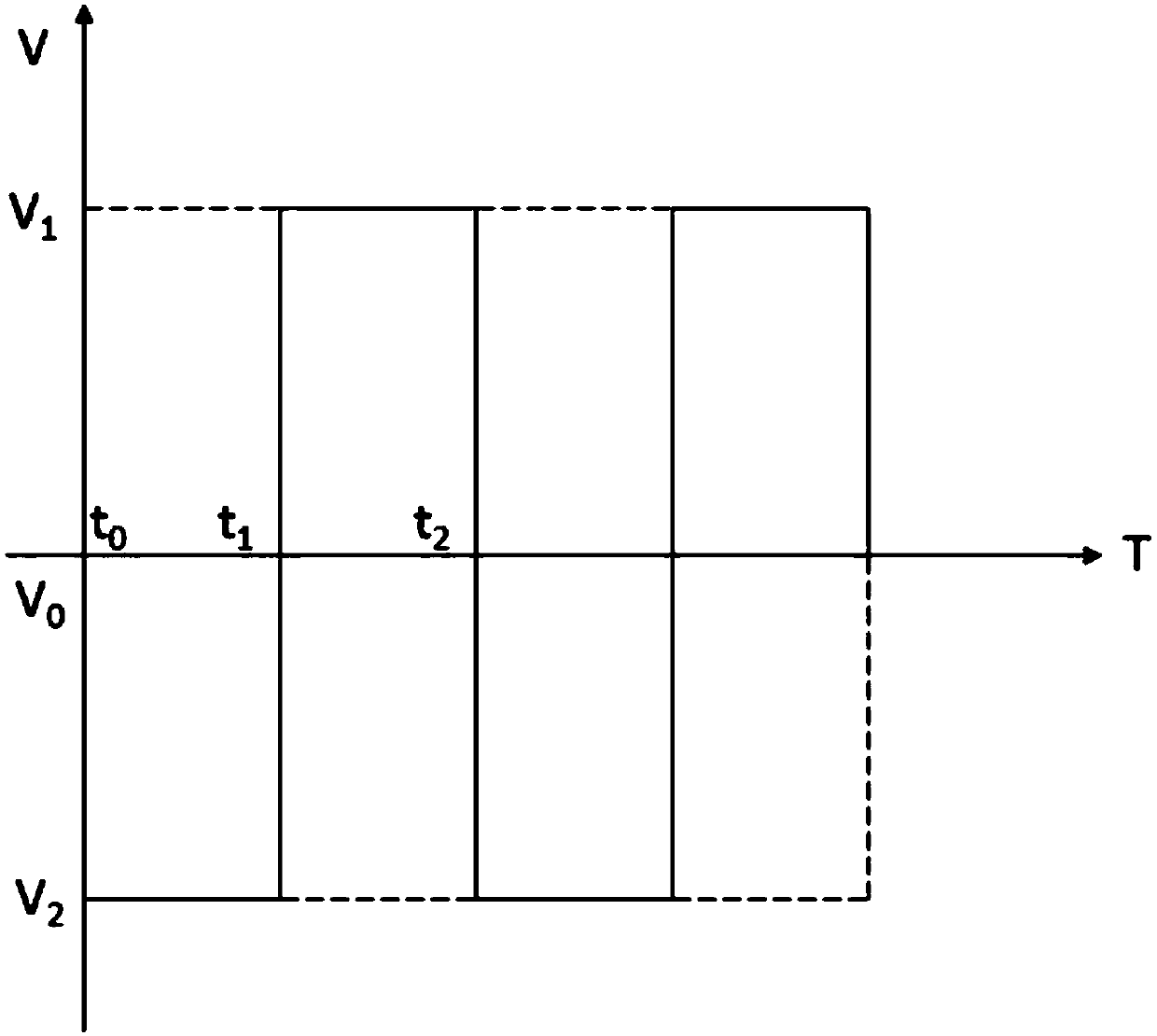

[0031] A method for generating electrowetting driving waveforms based on equal power, the power is expressed as:

[0032]

[0033] where g 1 (t) for t 0 to t 1 Waveform function during, g 2 (t) for t 1 to t 2 Waveform function during, v 1 A constant positive voltage connected to the pixel pole;

[0034] While maintaining the same power, where the driving stage, ie t 0 to t 1 stage driving voltage increases gradually, t 1 The voltage difference reaches the maximum value at any time;

[0035] Recovery phase, ie t 1 to t 2 stage, the voltage difference decreases to 0.

[0036] As an improvement of the technical solution, the driving stage waveform includes linear and parabolic shapes.

[0037] As an improvement of the technical solution, the waveform in the driving phase is a straight line wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com