A new resistance-capacitance composite chip and its manufacturing method

A composite chip and manufacturing method technology, which is applied in the manufacture of encapsulated/shell resistors, resistors, and resistors with negative temperature coefficients, etc., which can solve the problem of lack of overvoltage protection for resistor products, affecting normal operation of circuits, and easy damage, etc. problems, to achieve the effect of preventing damage or sudden changes in resistance, preventing sudden changes in voltage, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

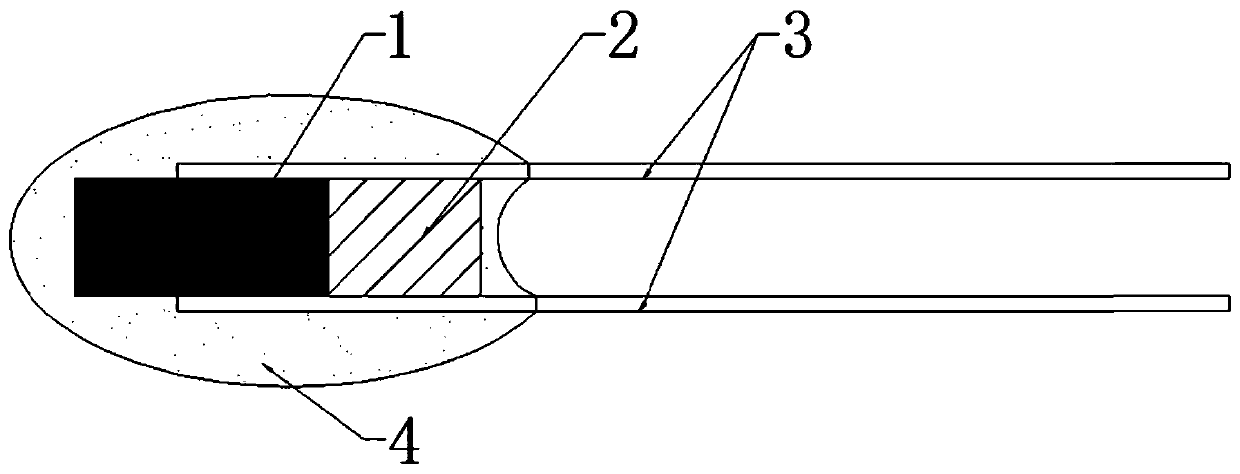

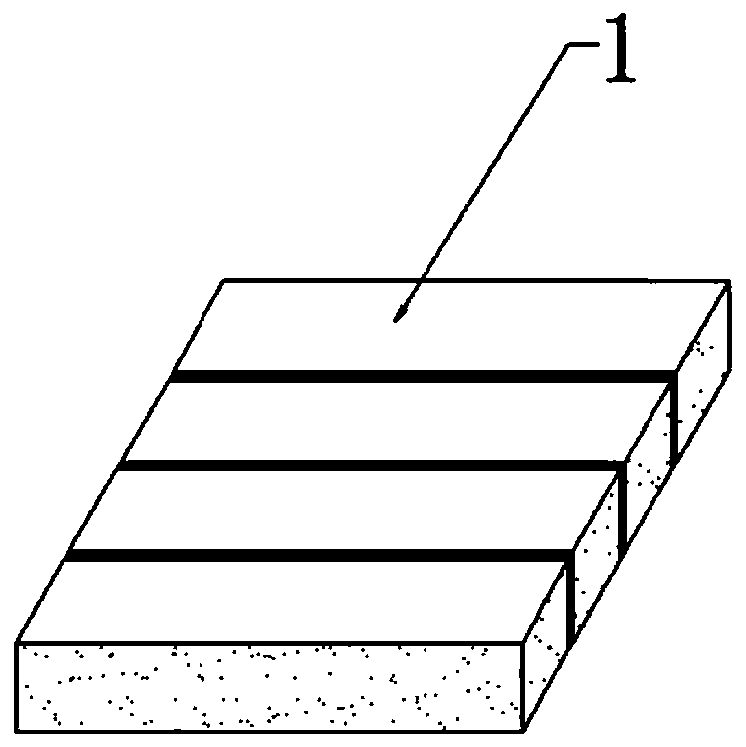

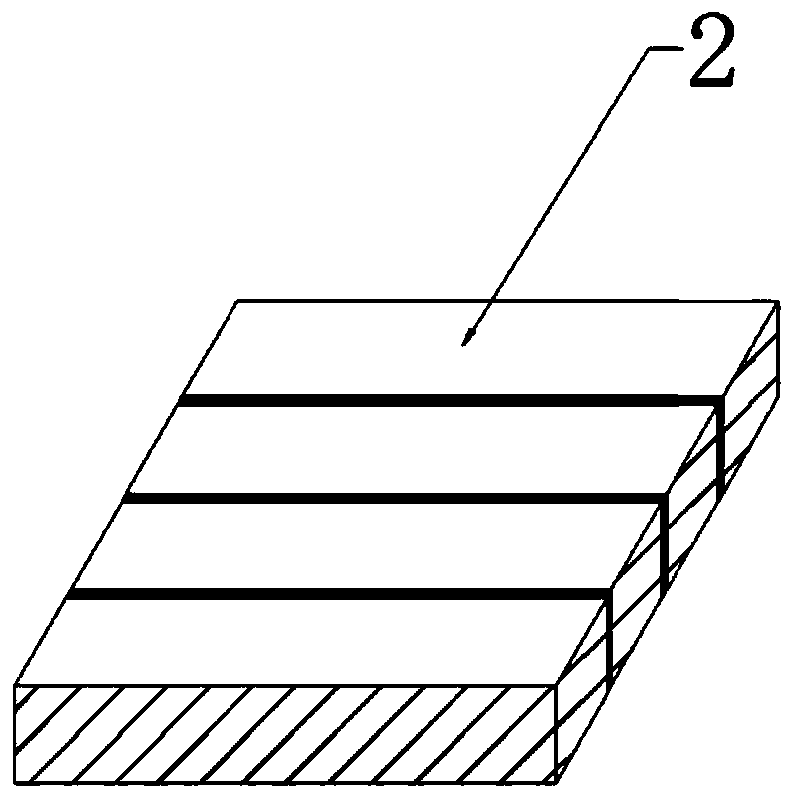

[0026] See figure 1 , Which is a schematic diagram of the structure of the novel resistance-capacitance composite chip of the present invention. The novel resistance-capacitance composite chip includes a resistance chip 1, a capacitor chip 2, two parallel leads 3 connected to electrodes on both sides of the resistance chip 1, and a protective layer 4 covering the outside of the resistance chip 1 and the capacitor chip 2. .

[0027] The resistor chip 1 is an NTC thermistor chip. The resistance chip 1 is clamped and fixed to the ends of the two leads 3, and the leads are soldered through a high-temperature tin furnace and high-temperature solder. The capacitor chip 2 is connected in parallel to the resistor chip 1 and is arranged between the two leads 3. The protective layer 4 is a glass protective layer.

[0028] Compared with the prior art, the novel resistance-capacitance composite chip of the present invention is provided with a capacitor chip connected in parallel with the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com