Electron beam sterilization method for bottle cap and electron beam sterilization device

A technology of electron beam and sterilization device, applied in the directions of bottle cap pretreatment, packaging sterilization, disinfection, etc., can solve problems such as corrosion of sterilization containers, and achieve the effects of increased processing speed, good sterilization, and reliable sterilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

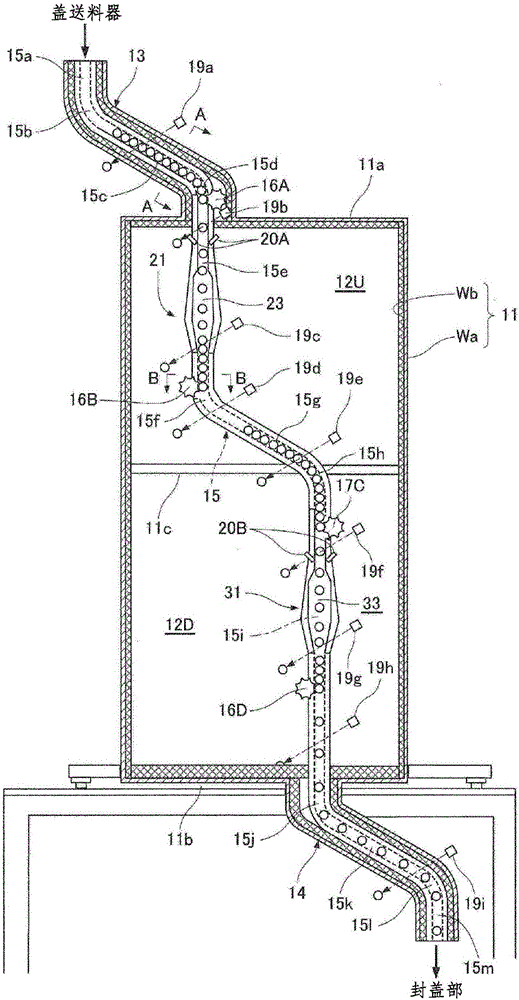

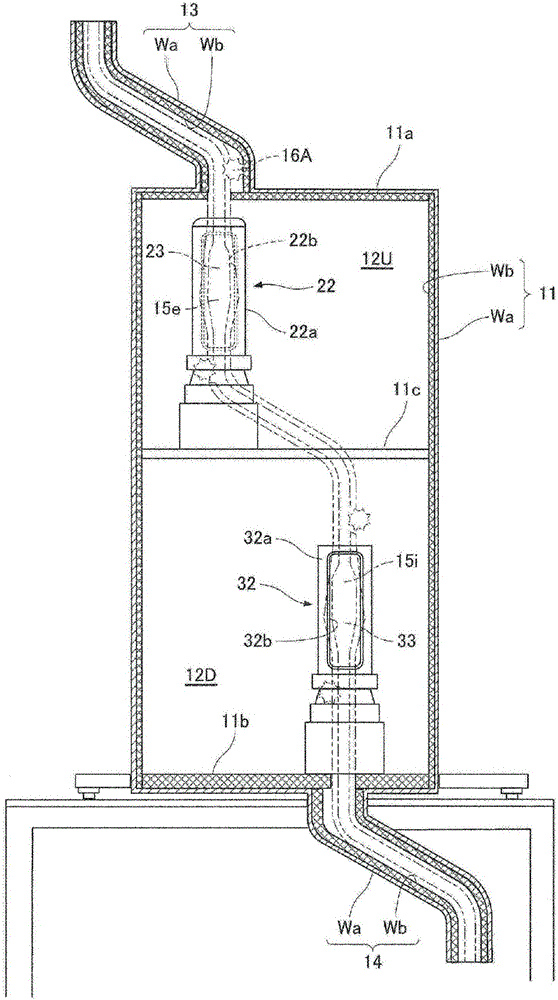

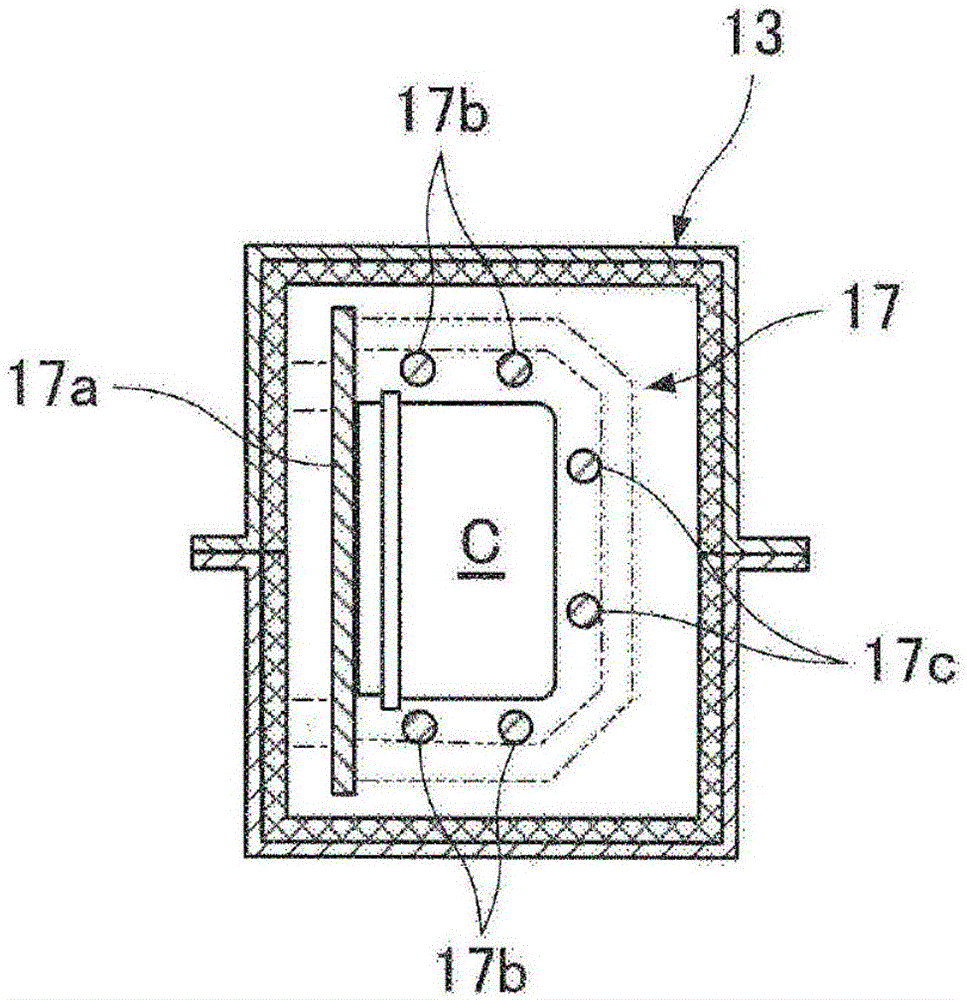

[0030] Embodiments of the present invention will be described below based on the drawings.

[0031] The bottle cap C has a closed surface Co formed on the top and an open surface Ci formed on the bottom. The electron beam sterilizing device for the bottle cap of the present invention makes the bottle cap C in a substantially horizontal posture with the cap axis passing through the center of the open surface Ci. It is dropped in a gas atmosphere such as air in a vertical direction, and irradiated with electron beams to sterilize.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com