Radial bearing arrangement in refrigeration compressor

A technology for refrigeration compressors and supports, applied in engine components, pump components, mechanical equipment, etc., can solve problems such as high wear and insufficient lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

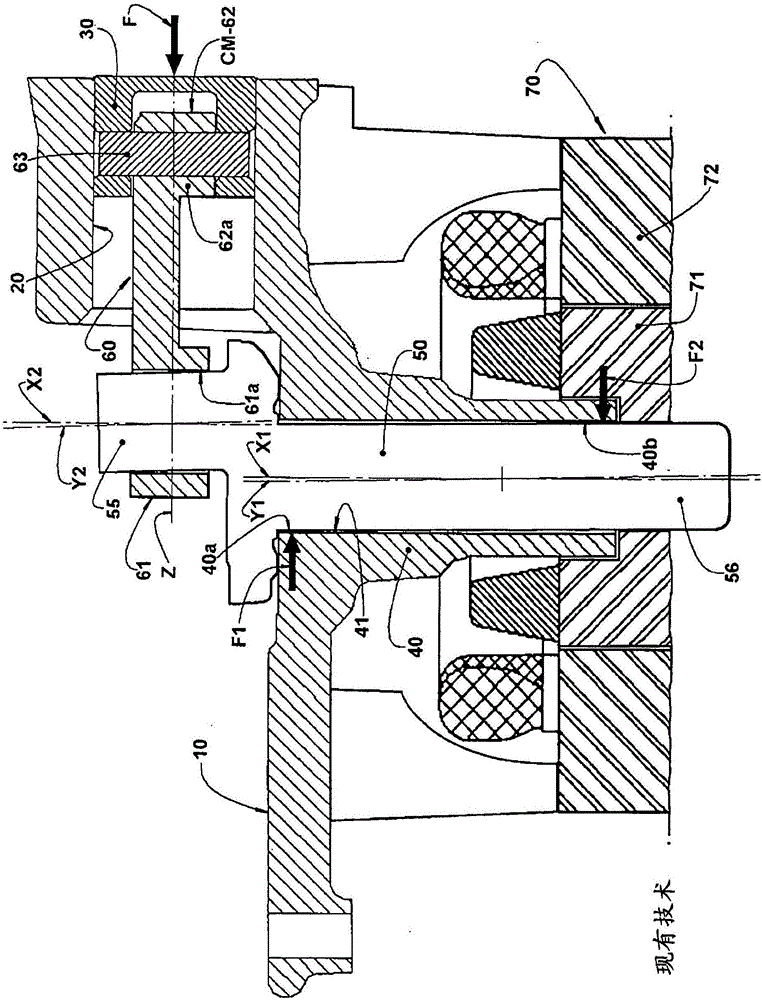

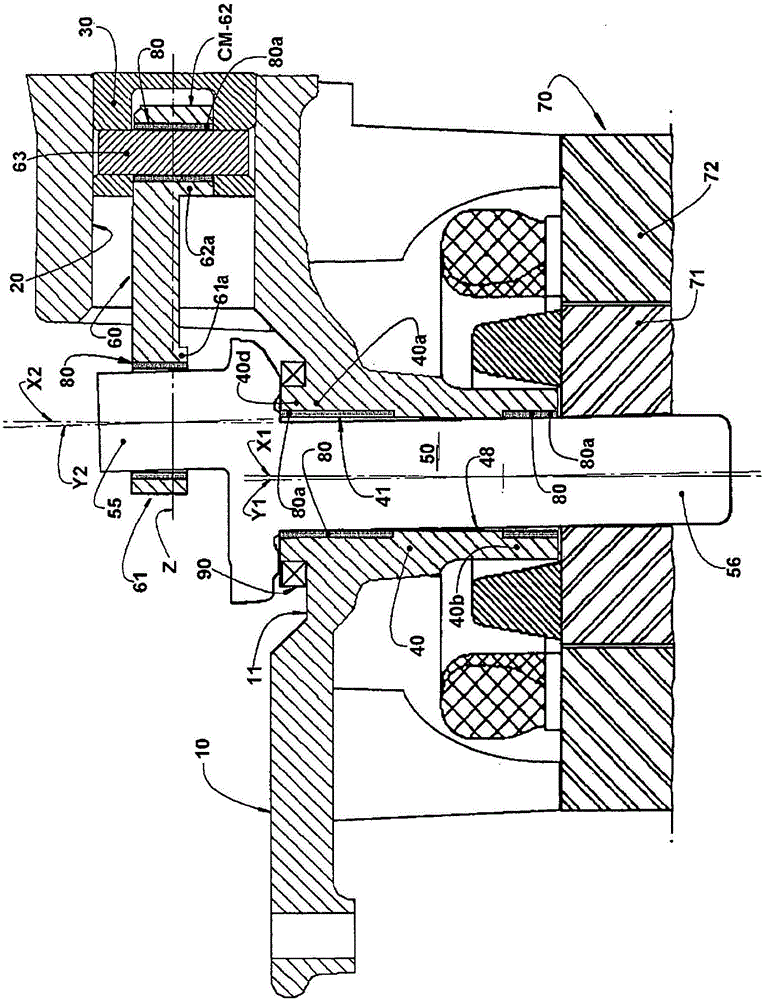

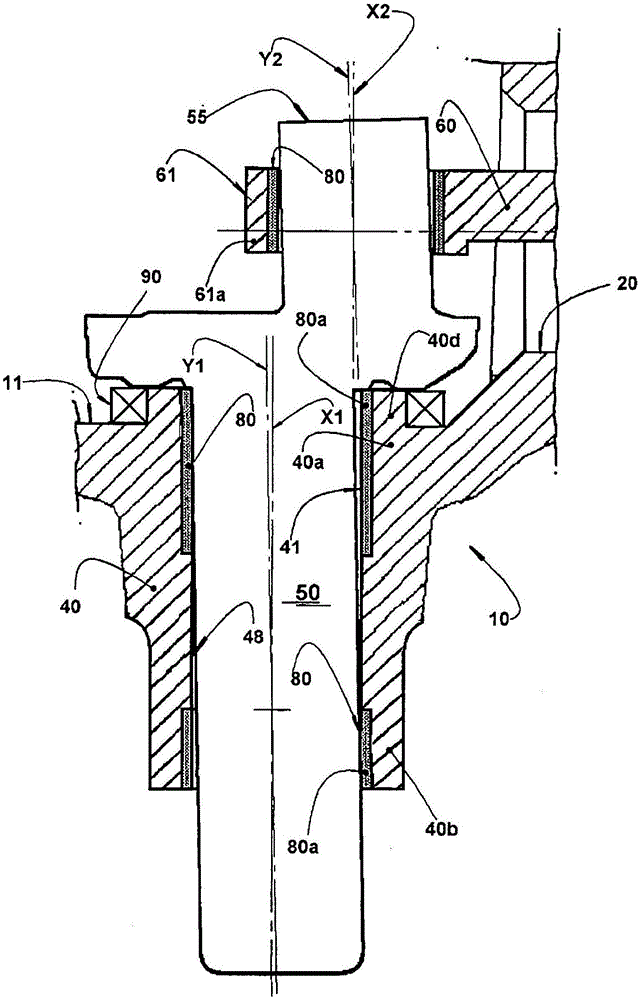

[0040] As mentioned above and shown in the drawings, the type of refrigeration compressor to which the radial support arrangement of the present invention is applied includes a crankcase 10 inside a housing (not shown) in a one-piece or non-one-piece The form bears a support hub 40 internally delimiting a radial support 41 with axis X1 and cylinder 20 with axis Z.

[0041] A crankshaft 50 with an axis Y1 is mounted inside the radial support 41 of the support hub 40 and comprises a free end 56 and an eccentric end 55 with an axis Y2 extending from the first end of the support hub 40 A portion 40a protrudes outward, and a free end protrudes outward from a second end portion 40b of the support hub 40 .

[0042] The piston 30 is housed in the cylinder 20 so as to be moved in a reciprocating manner within the cylinder by a connecting rod 60 having an end defining a larger aperture 61 and carrying coupling means CM to allow coupling of the connecting rod 60 to the opening of the pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com