X-ray inspection apparatus and operation method

An inspection device and X-ray technology, which are applied in the fields of radiological diagnosis instruments, radiological diagnostic image/data processing, medical science, etc., can solve the problems of increasing, decreasing, and difficult to achieve the radiation dose, and reduce the burden. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

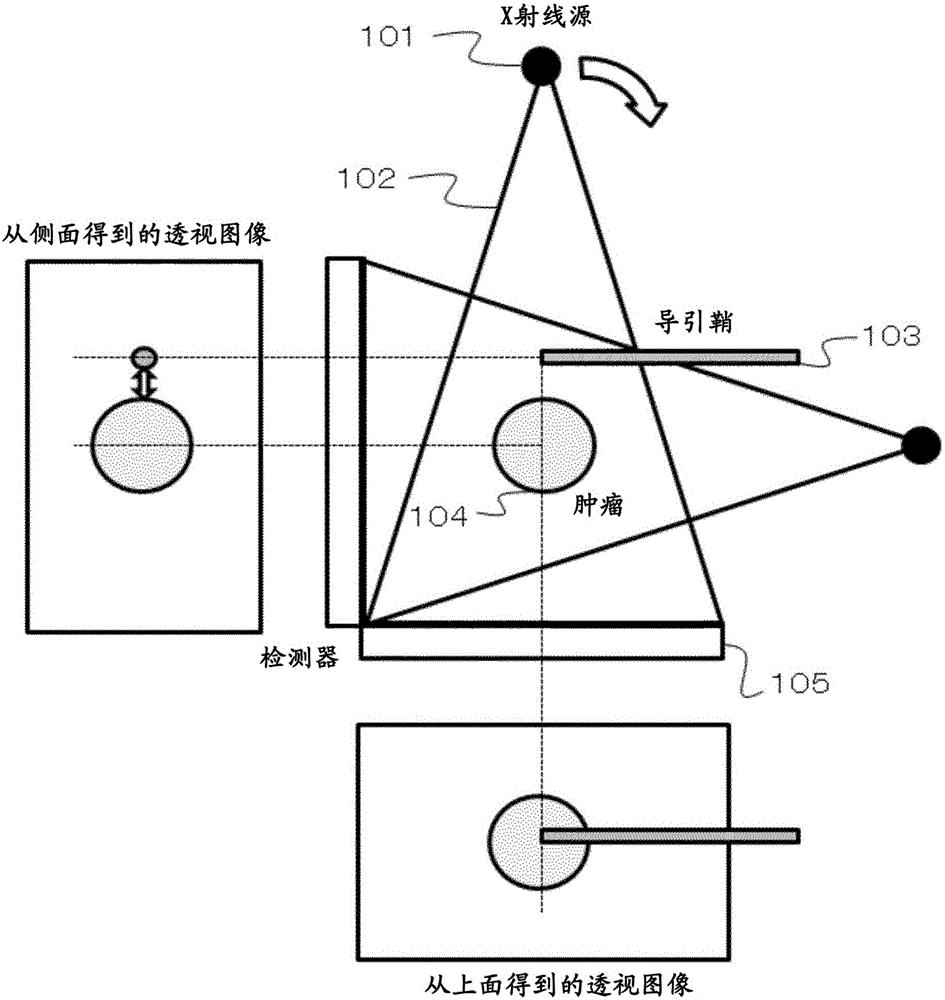

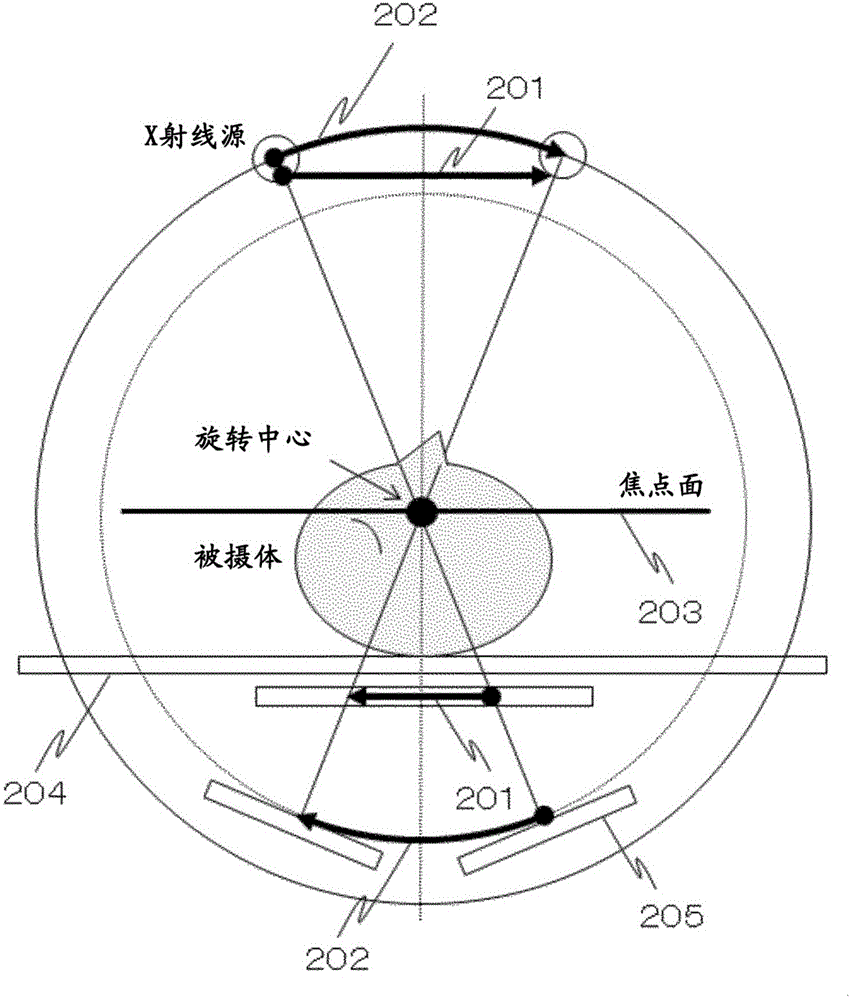

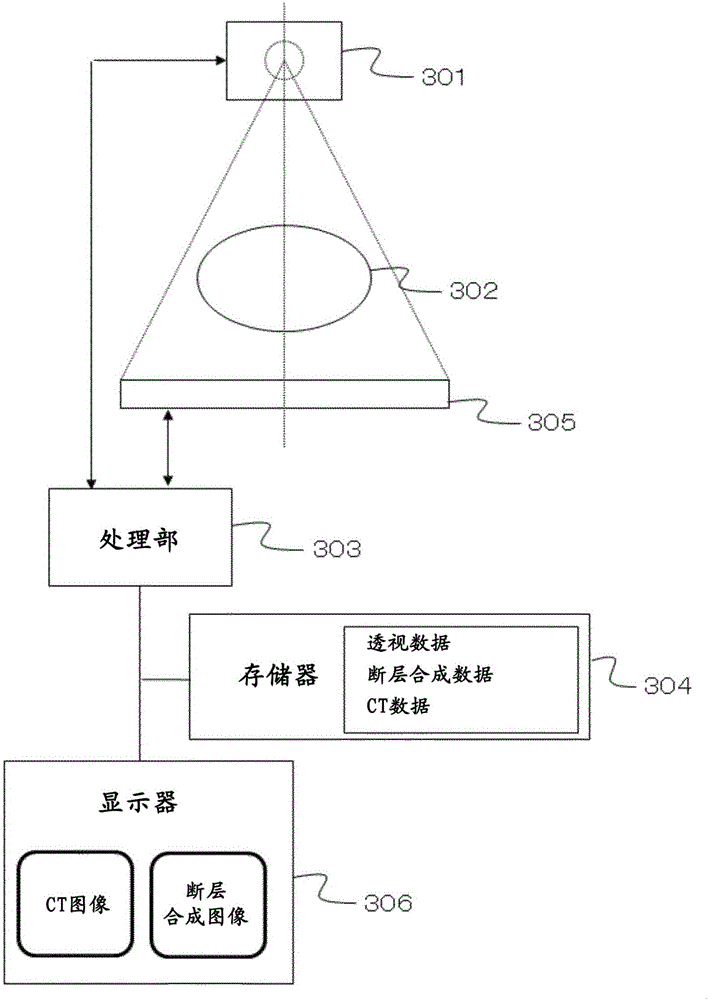

[0035] Hereinafter, an embodiment of an X-ray inspection apparatus capable of performing tomosynthesis imaging with reduced radiation dose will be described as a first embodiment. This embodiment is an embodiment of the following X-ray inspection apparatus and its operating method, that is, it has: an X-ray source 301, which irradiates an X-ray beam to an object 302; an X-ray detector 305, which is arranged opposite to the X-ray source, Detecting the transmitted X-ray of the object; the processing unit 303 processes the detection signal detected by the X-ray detector into an X-ray image; Determine the position of the second object and calculate the rotation angle range of the X-ray beam that can separate the two, obtain the detection signal while moving the X-ray source and the detector within the rotation angle range, and process the obtained detection signal Let it be an X-ray image instead.

[0036] image 3 One configuration example of the X-ray inspection apparatus acco...

no. 2 example

[0067] Next, as a second example, an example of an X-ray inspection apparatus that considers the cause of deterioration of a reconstructed image will be described. The present embodiment is an embodiment of the X-ray inspection device and its operating method having the following structures: an X-ray source that irradiates an X-ray beam to an object; an X-ray detector that is disposed opposite to the X-ray source, Detecting transmitted X-rays of the subject; a processing unit that processes detection signals detected by the X-ray detector into an X-ray image; and a display unit that displays the X-ray image, and the processing unit determines the distance between the first object and the second object Position, calculate the rotation angle range of the X-ray beam that can separate the two and the first object and the third object do not overlap, and obtain the detection signal while moving the X-ray source and detector within the rotation angle range, and the obtained The dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com