Sheet material cutting device and sheet material connecting device using the same

A technology of cutting device and connecting device, which is applied in the field of sheet cutting device and sheet connecting device, and can solve the problems of dust generation at the cutting end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

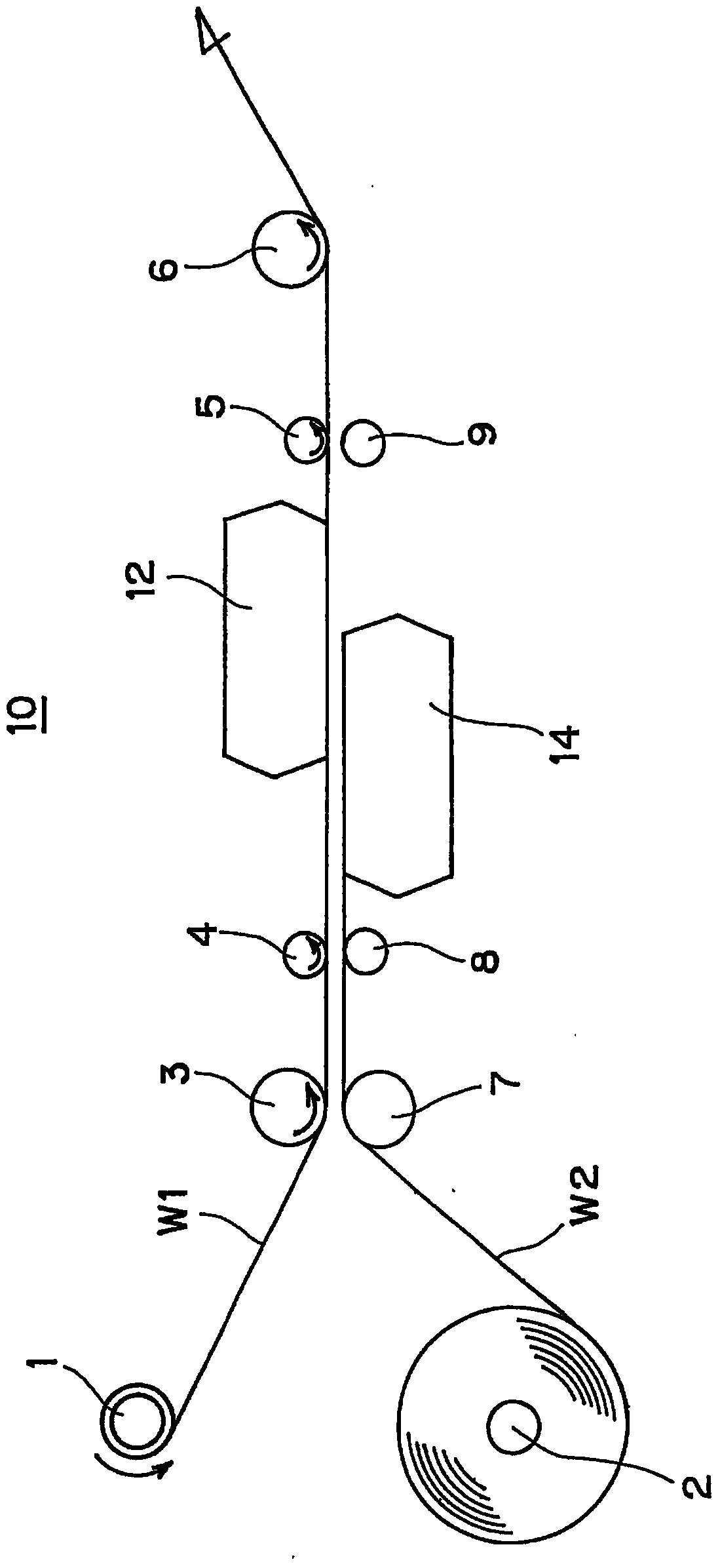

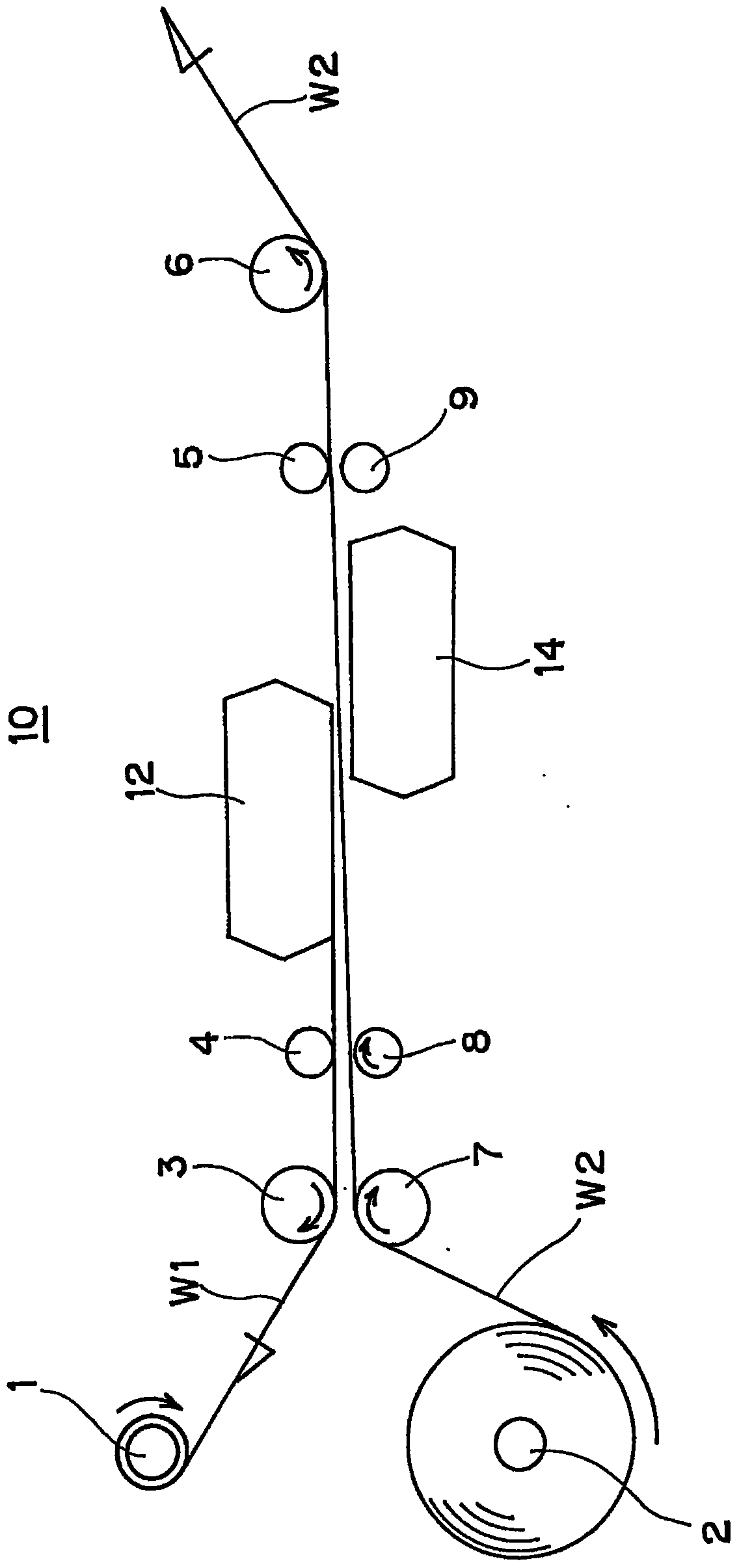

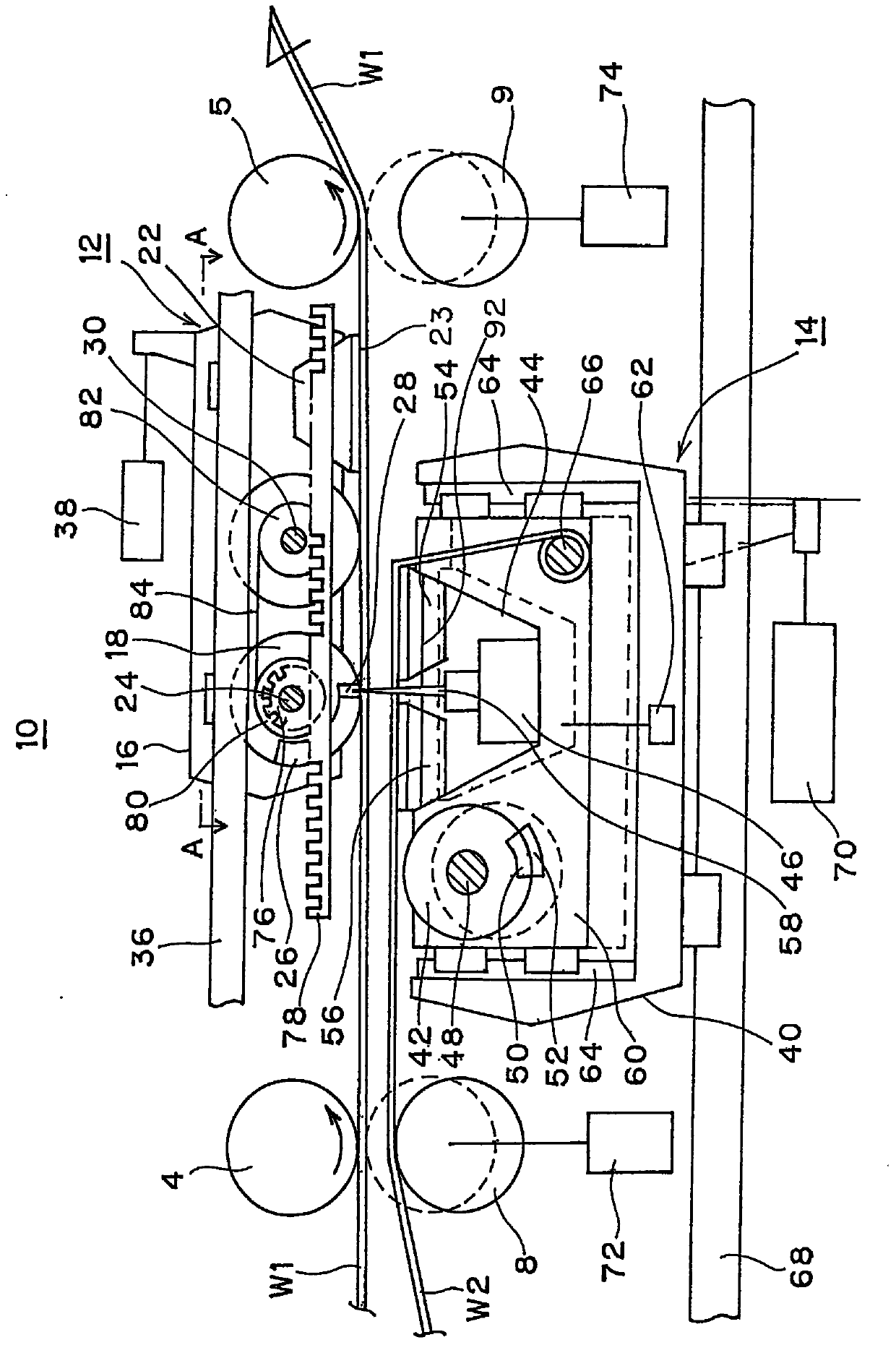

[0029] Below, based on Figure 1 to Figure 21 The connecting device 10 of the sheet W according to one embodiment of the present invention will be described. The connection device 10 uses a suction device 100 , a cutting device 46 , and a negative pressure device 150 . Here, the "sheet W" refers to a long sheet, such as fabric, paper, film, metal foil, and the like. In addition, in the connecting device 10 , the "input side" refers to the upstream where the sheet W is conveyed, and the "output side" refers to the downstream where the sheet W is to be conveyed.

[0030] In the connecting device 10, such as figure 1 As shown, the remaining old sheet W1 wound on the previous core 1 is reduced, so the new sheet W2 wound on the new core 2 is connected after the old sheet W1.

[0031] Such as figure 1 and figure 2 As shown, the old sheet W1 and the new sheet W2 are conveyed via the conveyance path in the horizontal direction. Such as figure 1 As shown, the old sheet W1 passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com