Model building method and detection device of gm refrigerator compressor unit

A construction method and compressor technology, applied in the direction of machines/engines, pump testing, mechanical equipment, etc., can solve the problem of fixed, failure to summarize the compressor flow, efficiency characteristics, and failure to consider the complete machine of the compressor refrigerator Influence and other issues, to achieve the effect of uniform internal pressure and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

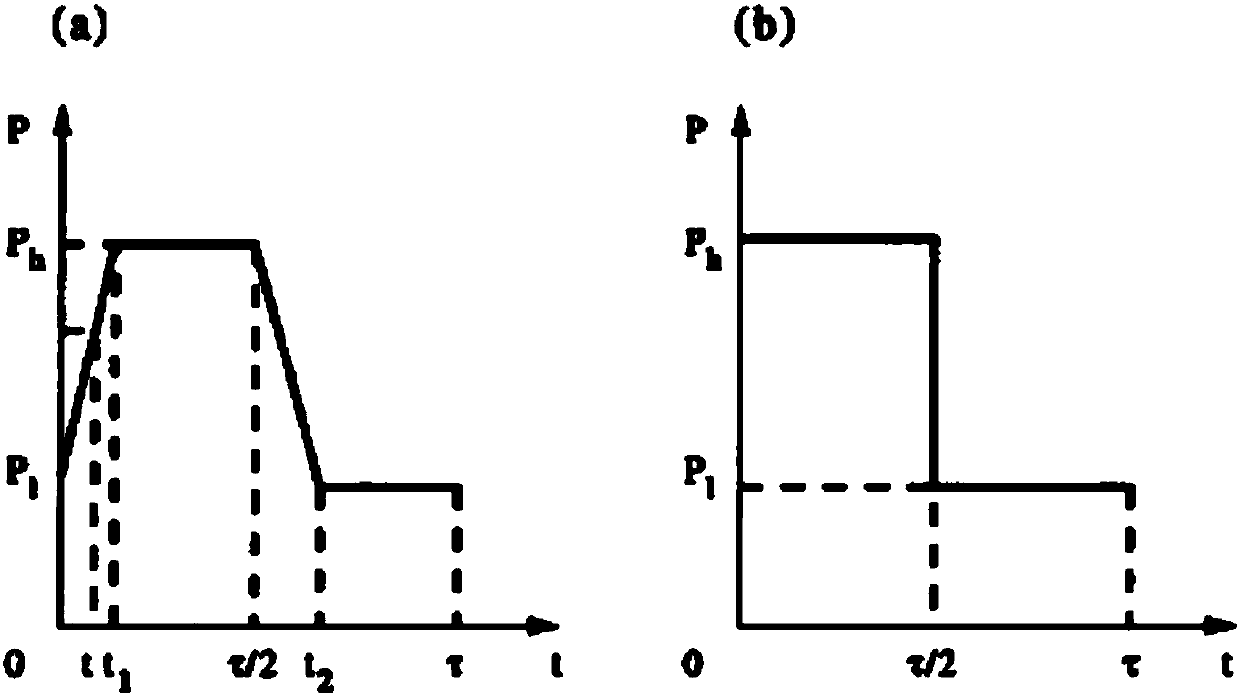

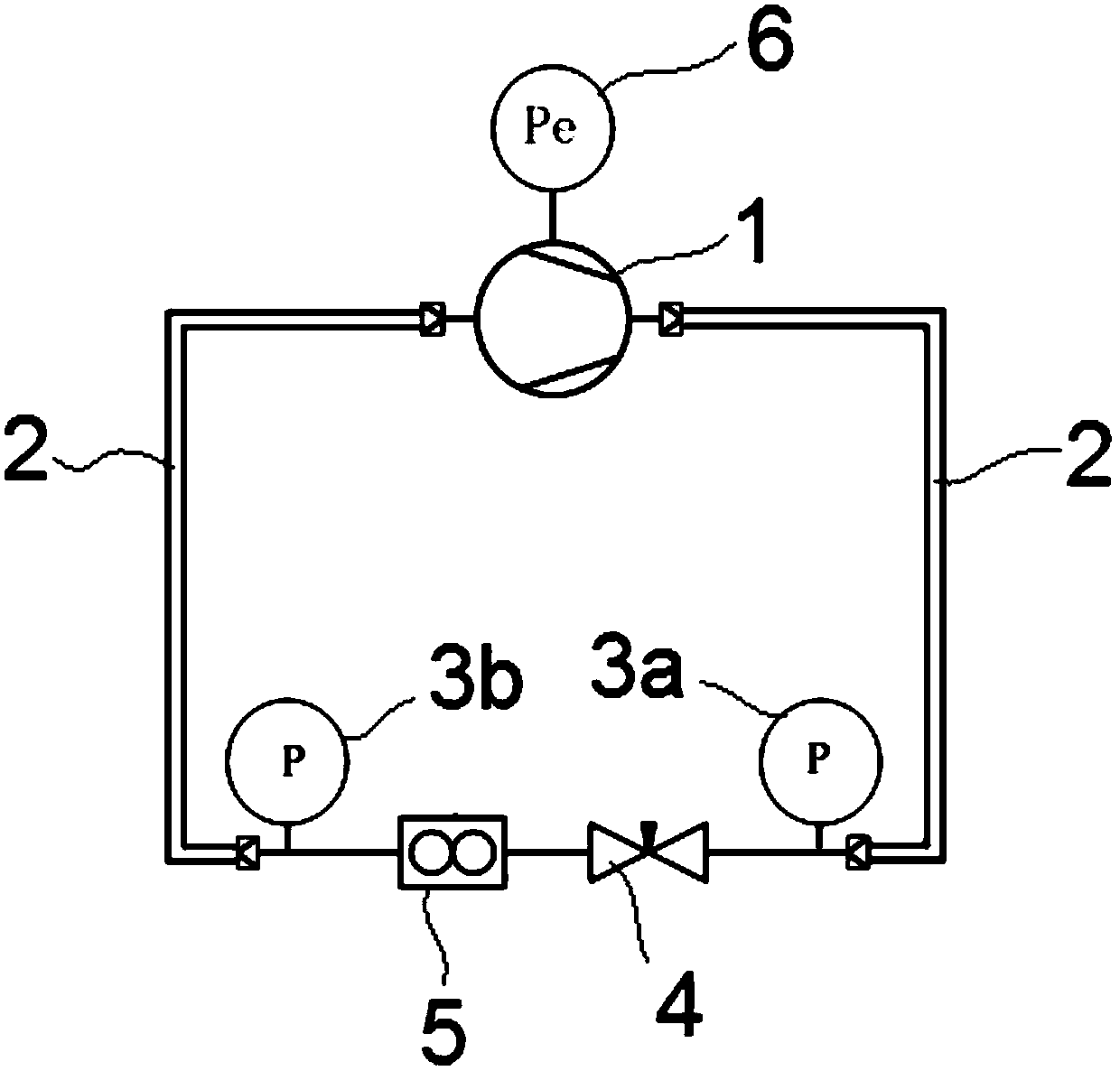

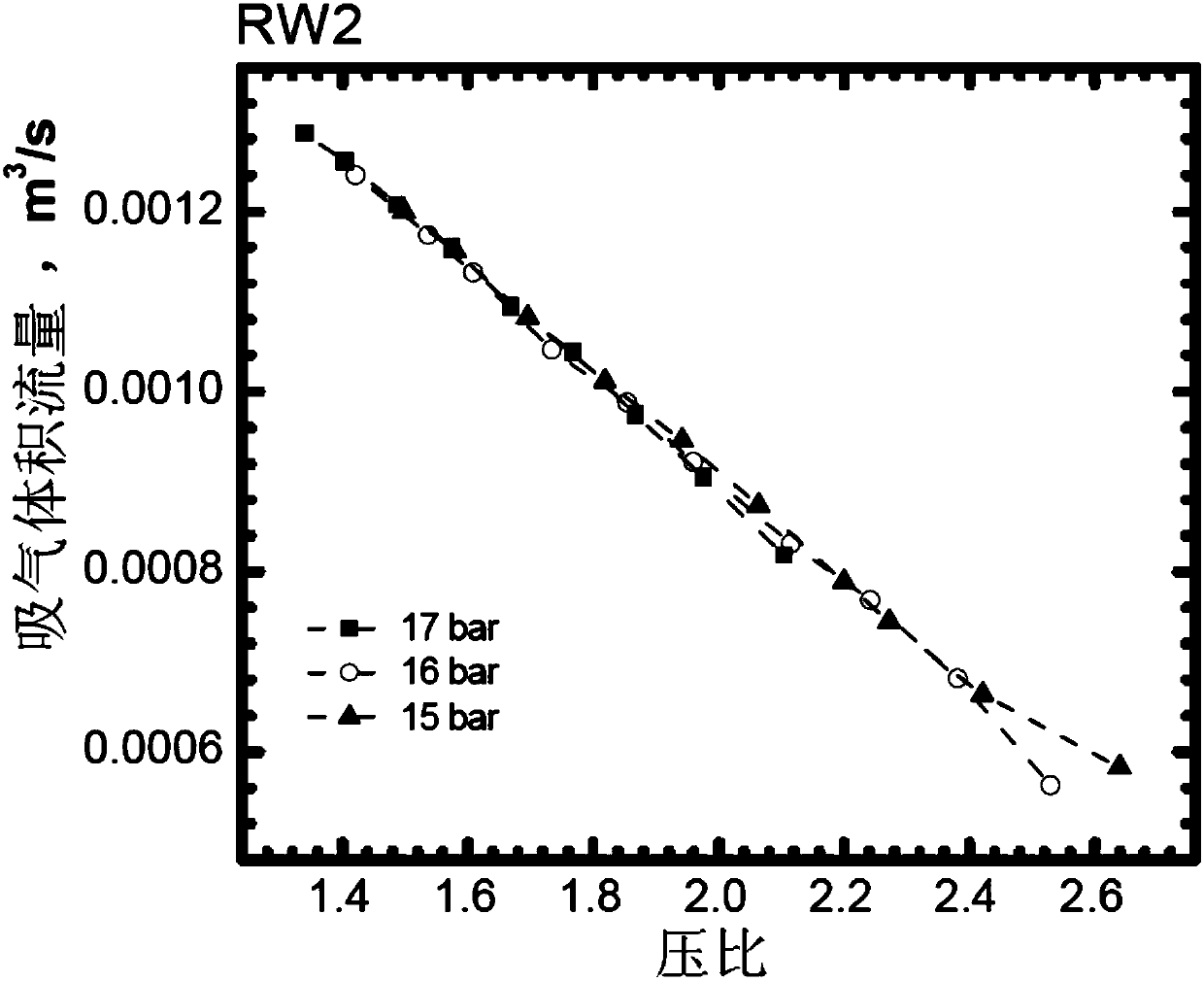

[0068] Taking the compressor RW2 as an example, its packaging contains components such as a pressure bag, a water-cooled heat exchanger, an oil separator, and an adsorber. The compressor is selected for testing, and the inflation pressure of the pulse tube refrigerator driven by it is generally 1.7MPa. Accordingly, three groups of inflation pressures of 1.7MPa, 1.6MPa and 1.5MPa were selected for testing. according to figure 2 The test system is built as shown, the RW2 compressor unit is connected with the metal hose 2, the regulating valve 4, the mass flow meter 5 and the metal hose 2 through the air circuit in sequence to form a loop. The suction and discharge pressure of the compressor is adjusted through the regulating valve 4, the mass flow meter 5 measures the mass flow rate, the power consumption of the compressor is measured by the power meter 6, and the suction and discharge pressure is measured by two pressure gauges (respectively pressure gauge 3a and pressure gaug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com