Power lithium ion battery grouping method

A power battery and lithium-ion technology, which is applied in the field of lithium iron phosphate power battery assembly, can solve the problems of not fully reflecting the essential differences of power batteries, stricter index requirements, and complicated processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

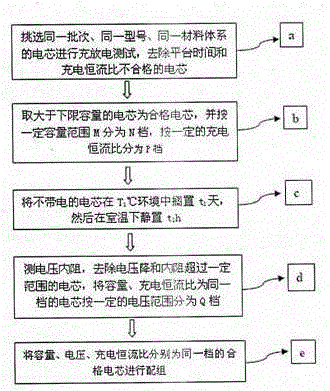

[0017] The present invention will be further described in detail through specific examples below. In this example, a lithium iron phosphate battery cell with a nominal capacity of 5AH is used to assemble a 16V20A battery module. The specific steps are as follows:

[0018] ①Select 100pcs of 32650 lithium iron phosphate batteries with a nominal capacity of 5AH of the same batch, same model, and same material system;

[0019] ②Use the pre-charged cell at room temperature to divide the capacity at a rate of 1C in a capacity-dividing test cabinet, discharge it to 2.0V at a constant current, and leave it for 15 minutes. Cycle 1.5 times, take the last discharge capacity as the actual capacity of the battery, select a battery with a capacity of 5100-5150mAh, a platform time of more than 46 minutes, and a charging constant current ratio of 90%-95%;

[0020] ③Put the uncharged cells selected in step ② in an environment of 45°C for 10 days, then at room temperature for 24 hours, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com