Fermented lentinula edodes flavor paste and processing method thereof

A processing method and a technology for flavor sauce, applied in the field of food processing, can solve the problems affecting the development and pace of industrial modernization in the food field, discarding shiitake stems, waste of raw materials, etc., and achieve the effect of favorable opportunities and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

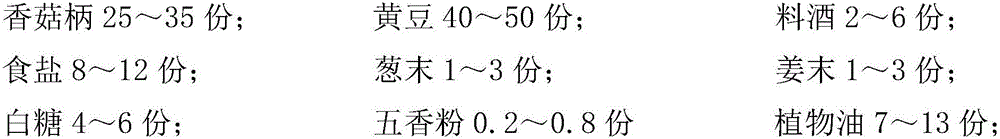

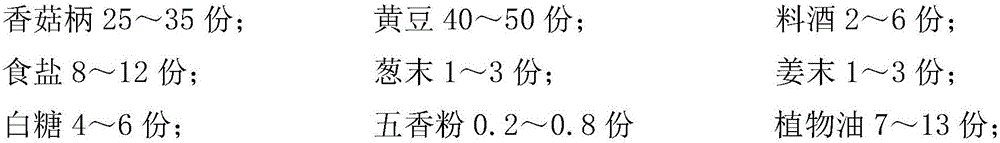

Method used

Image

Examples

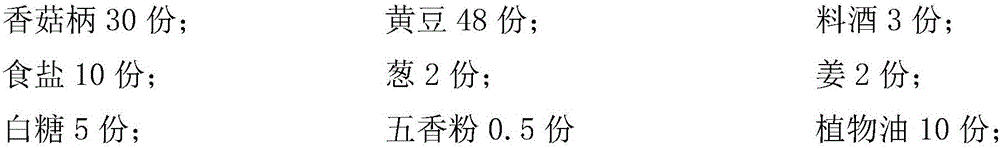

Embodiment 1

[0041] (1) Raw material pretreatment

[0042] A. Pretreatment of shiitake mushroom stalks: select 30 parts of fresh, fragrant shiitake mushroom stalks to remove surface impurities; soak the selected shiitake mushroom stalks at 50°C for 2.5 hours according to the material-to-water mass ratio of 1:20; After saturated with water, remove and cut into square cubes with a side length of 3mm for later use;

[0043] B, soybean paste preparation: its concrete processing steps are as follows:

[0044] (b1) Selection of raw materials: select 48 parts of soybeans with full grains, no moths, and no mildew;

[0045] (b2) Cleaning and soaking: wash away impurities on the surface of soybeans with running water, add water 4 times the weight of soybeans, and soak at room temperature for 12 hours until the surface of soybeans absorb water and swell without wrinkles;

[0046] (b3) Steaming and cooling: remove the soaked soybeans in step (b2), drain the water, cook at 120°C and 0.1MPa under high...

Embodiment 2

[0055] (1) Raw material pretreatment

[0056] A. Pretreatment of shiitake mushroom stalks: select 25 parts of fresh, fragrant shiitake mushroom stalks to remove surface impurities; soak the selected shiitake mushroom stalks at 45°C for 2 hours according to the mass ratio of material to water at 1:15; when the shiitake mushroom stalks absorb water After saturation, remove and cut into square cubes with a side length of 2 mm for later use;

[0057] B, soybean paste preparation: its concrete processing steps are as follows:

[0058] (b1) Raw material selection: select 40 parts of soybeans with full grains, no moths, and no mildew;

[0059] (b2) Cleaning and soaking: wash away impurities on the surface of soybeans with running water, add clear water three times the weight of soybeans, and soak at room temperature for 10 hours until the surface of soybeans absorb water and swell without wrinkles;

[0060] (b3) Steaming and cooling: remove the soaked soybeans in step (b2), drain t...

Embodiment 3

[0069] (1) Raw material pretreatment

[0070] A, shiitake stalk pretreatment: select 35 parts of fresh, fragrant shiitake stalks, remove surface impurities; and select a good shiitake stalk according to the material-to-water mass ratio: 25, soak 3h at 55°C; when the shiitake stalks are saturated with water Finally, fish out and cut into square cubes with a side length of 5 mm for later use;

[0071] B, soybean paste preparation: its concrete processing steps are as follows:

[0072] (b1) Selection of raw materials: select 50 parts of soybeans with full grains, no moths, and no mildew;

[0073] (b2) Cleaning and soaking: wash away impurities on the surface of soybeans with running water, add water 5 times the weight of soybeans, and soak at room temperature for 14 hours until the surface of soybeans absorbs water and swells without wrinkles;

[0074] (b3) Steaming and cooling: remove the soaked soybeans in step (b2), drain the water, cook at 121°C and 0.1MPa under high temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com