Production method and product of andrias davidianus purple perilla noodles

A technique of giant salamander, noodles, applied in the field of food processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

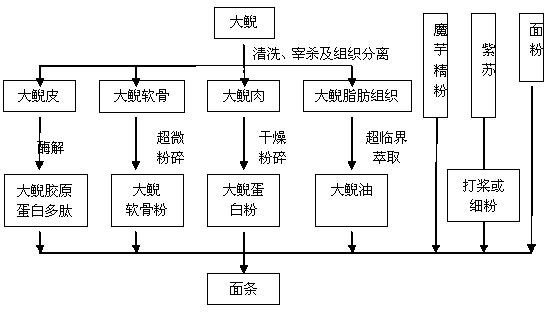

Image

Examples

Embodiment 1

[0024] A kind of production method of giant salamander perilla noodles, concrete steps are as follows:

[0025] (1) Tissue separation: after the giant salamander is slaughtered, the internal organs are discarded, and the tissues are separated into: giant salamander skin, giant salamander cartilage, giant salamander viscera, giant salamander fat and other tissues;

[0026] (2) Enzymatic hydrolysis: crush the giant salamander skin into meat pulp, add active enzymes, and carry out enzymatic hydrolysis under the condition of 20-40°C, enzymatically hydrolyze the collagen into protein polypeptides, and obtain giant salamander collagen polypeptides;

[0027] (3) Superfine pulverization: the giant salamander cartilage is pulverized into a fine powder of about 1000 mesh through superfine pulverization technology to obtain giant salamander cartilage powder;

[0028] (4) Crushing of meat: drying and pulverizing the separated giant salamander meat into fine powder to obtain giant salamand...

Embodiment 2

[0033] A kind of production method of giant salamander perilla noodles, concrete steps are as follows:

[0034] (1) Tissue separation: after the giant salamander is slaughtered, the internal organs are discarded, and the tissues are separated into: giant salamander skin, giant salamander cartilage, giant salamander viscera, giant salamander fat and other tissues;

[0035] (2) Enzymatic hydrolysis: crush the giant salamander skin into meat pulp, add active enzymes, and carry out enzymatic hydrolysis under the condition of 20-40°C, enzymatically hydrolyze the collagen into protein polypeptides, and obtain giant salamander collagen polypeptides;

[0036] (3) Superfine pulverization: the giant salamander cartilage is pulverized into a fine powder of about 1000 mesh through superfine pulverization technology to obtain giant salamander cartilage powder;

[0037] (4) Crushing of meat: drying and pulverizing the separated giant salamander meat into fine powder to obtain giant salamand...

Embodiment 3

[0042] A kind of production method of giant salamander perilla noodles, concrete steps are as follows:

[0043] (1) Tissue separation: after the giant salamander is slaughtered, the internal organs are discarded, and the tissues are separated into: giant salamander skin, giant salamander cartilage, giant salamander viscera, giant salamander fat and other tissues;

[0044] (2) Enzymatic hydrolysis: crush the giant salamander skin into meat pulp, add active enzymes, and carry out enzymatic hydrolysis under the condition of 20-40°C, enzymatically hydrolyze the collagen into protein polypeptides, and obtain giant salamander collagen polypeptides;

[0045] (3) Superfine pulverization: the giant salamander cartilage is pulverized into a fine powder of about 1000 mesh through superfine pulverization technology to obtain giant salamander cartilage powder;

[0046] (4) Crushing of meat: drying and pulverizing the separated giant salamander meat into fine powder to obtain giant salamand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com