Magic tape and manufacturing method thereof

A Velcro, non-woven technology, applied in clothing, applications, fasteners, etc., can solve problems such as unfavorable high-speed and stable production, unclear printing patterns, air leakage of non-woven materials, etc. The effect of full effect and high compound fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below through specific embodiments.

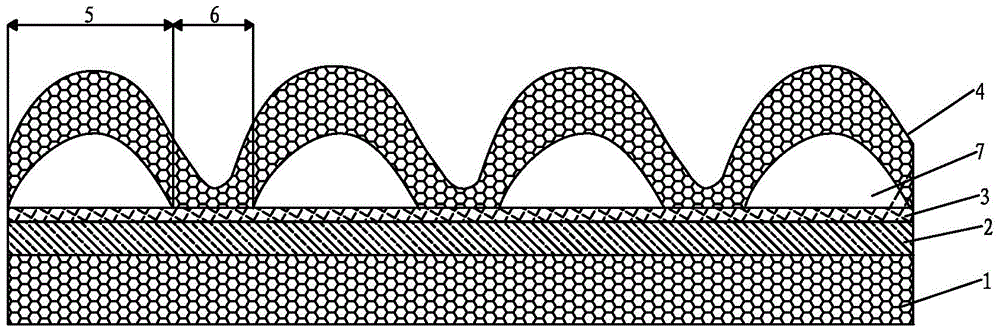

[0026] refer to figure 1 , a Velcro, comprising an inner layer non-woven fabric 1, a surface layer non-woven fabric 4 and an interlayer film layer 2, the interlayer film layer 2 is located between the inner layer non-woven fabric 1 and the surface layer non-woven fabric 4, three layers The material is bonded and fixed by heat compression, and the surface of the interlayer film layer 2 (any surface is acceptable) is printed with an ink layer 3 . The surface layer non-woven fabric 4 is hot-press bonded to the surface of the interlayer film layer 2 and forms a plurality of air cushion regions 5 and fixed regions 6 distributed at intervals, and the fixed region 6 is located between two adjacent air cushion regions 5 . The surface non-woven fabric 4 of the air cushion area 5 is separated from the interlayer film layer 2 to form a cavity 7, and the surface non-woven fabric 4 of the fixed ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com