Coating type BOPP pre-coating film capable of embossing and preparation method of coating type BOPP pre-coating film

A pre-coating and embossing technology, used in coatings, polyurea/polyurethane coatings, film/flaky adhesives, etc., can solve the heat shrinkage wrinkles of the base film, affecting the composite effect, and insufficient composite fastness, etc. problems, to achieve the effect of increasing adsorption capacity, increasing bond strength, and reducing uneven bond fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

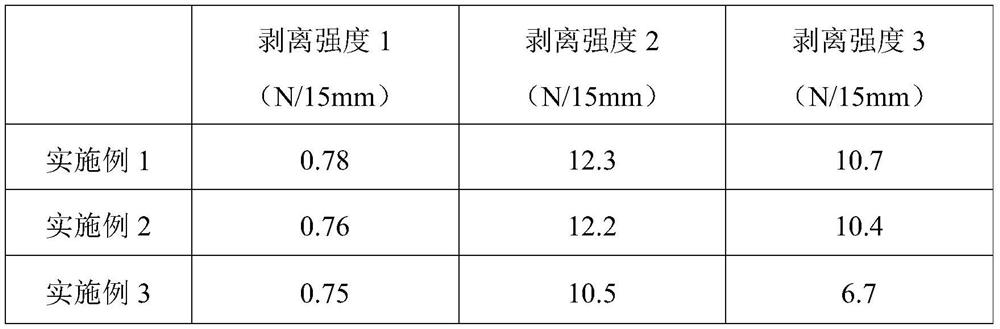

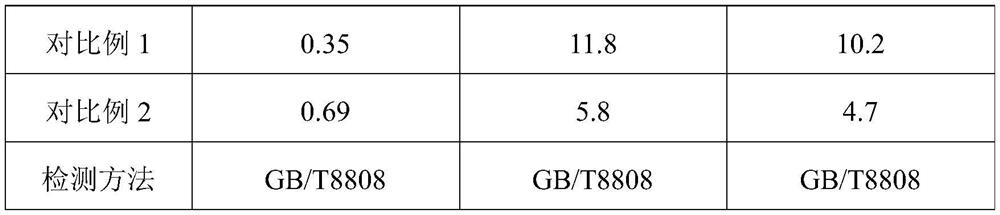

Embodiment 1

[0036] A coating type BOPP embossable pre-coating film, comprising a base material layer, a hot-melt adhesive layer and a coating layer arranged in sequence; the hot-melt adhesive layer includes the following raw materials in parts by mass: 90 parts of ethylene-vinyl acetate polymer , 10 parts of N,N-4,4-diphenylmethane type bismaleimide resin; the coating layer is prepared from a modified polyurethane solution, wherein the modified polyurethane solution is made of the following mass parts of raw materials in a solvent The reaction is obtained: 85 parts of polyurethane resin, 12 parts of dimethyl triphenyl ethanesulfonic acid isocyanate, 3 parts of maleic anhydride, the solvent is obtained by mixing water and absolute ethanol in a volume ratio of 8:2, The preparation method is as follows: adding a polyurethane prepolymer, dimethyl triphenyl ethane sulfonic acid isocyanate and maleic anhydride into a solvent, and stirring and reacting at normal temperature for 30 minutes to obta...

Embodiment 2

[0043] A coating type BOPP embossable pre-coating film, comprising a base material layer, a hot-melt adhesive layer and a coating layer arranged in sequence; the hot-melt adhesive layer comprises the following raw materials in parts by mass: 85 parts of ethylene-vinyl acetate polymer , 5 parts of N,N-4,4-diphenylmethane type bismaleimide resin; the coating layer is prepared from a modified polyurethane solution, wherein the modified polyurethane solution is made of the following mass parts of raw materials in a solvent Reaction made: 80 parts of polyurethane prepolymer, 10 parts of dimethyl triphenylethane sulfonic acid isocyanate, 1 part of maleic anhydride, the solvent is mixed with water and absolute ethanol in a volume ratio of 8:2 The preparation method is as follows: adding polyurethane prepolymer, dimethyl triphenyl ethane sulfonic acid isocyanate and maleic anhydride into a solvent, and stirring and reacting at normal temperature for 30 minutes, and then the substrate l...

Embodiment 3

[0050] A coating type BOPP embossable pre-coating film, comprising a base material layer, a hot-melt adhesive layer and a coating layer arranged in sequence; the hot-melt adhesive layer includes the following raw materials in parts by mass: 100 parts of ethylene-vinyl acetate polymer , 15 parts of N,N-4,4-diphenylmethane type bismaleimide resin; the coating layer is prepared from a modified polyurethane solution, wherein the modified polyurethane solution is made of the following mass parts of raw materials in a solvent Reaction made: 90 parts of polyurethane prepolymer, 15 parts of dimethyl triphenyl ethane sulfonic acid isocyanate, 5 parts of maleic anhydride, the solvent is mixed with water and absolute ethanol in a volume ratio of 8:2 The preparation method is as follows: adding a polyurethane prepolymer, dimethyl triphenyl ethane sulfonic acid isocyanate and maleic anhydride into a solvent, and stirring and reacting at normal temperature for 30 min to obtain the obtained p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com