Polypropylene film for cold mounting composite film, preparation method of polypropylene film and cold mounting composite film

A polypropylene film and composite film technology, applied in chemical instruments and methods, applications, household appliances, etc., can solve problems such as unfavorable lamination of films and printed parts, large unwinding force, and numerous processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

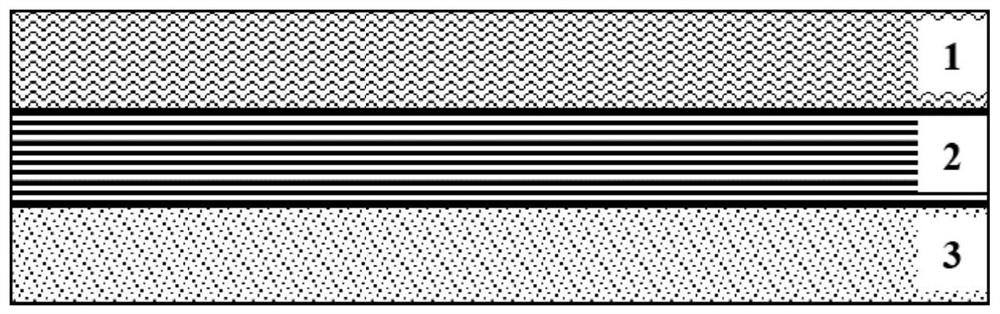

[0047] The polypropylene film of the cold lamination composite film of this embodiment, please refer to figure 1 , including a first surface layer 1, a core layer 2 and a second surface layer 3 arranged in sequence.

[0048] The first surface layer 1 is: 100wt% polymethylpentene copolymer (melt index is 4.6g / 10min, melt index test conditions: melting temperature is 230°C, load weight is 2.16kg);

[0049] Core layer 2 is: 99.8wt% homopolypropylene (98% isotacticity, melt index is 3g / 10min, melt index test conditions: melting temperature is 230°C, load weight is 2.16kg), 0.2wt% monohard fatty acid glycerides;

[0050] The second surface layer 3 is: 99.8wt% homopolypropylene (98% isotacticity, melt index is 3g / 10min, melt index test conditions: melting temperature is 230°C, load weight is 2.16kg), 0.2wt% Silicon oxide (particle size is 5 μm);

[0051] The total thickness of the prepared product is 23 μm, the thickness of the first skin layer 1 is 1 μm, the thickness of the cor...

Embodiment 2

[0056] The polypropylene film of the cold lamination composite film of this embodiment, please refer to figure 1 , including a first surface layer 1, a core layer 2 and a second surface layer 3 arranged in sequence.

[0057] The first surface layer 1 is: 80wt% polymethylpentene copolymer (melt index is 4.6g / 10min, melt index test conditions: melting temperature is 230°C, load weight is 2.16kg), 20wt% methylpentene-propylene Copolymer (melt index is 10g / 10min, melt index test conditions: melting temperature is 230°C, load weight is 2.16kg);

[0058] Core layer 2 is: 99.8wt% homopolypropylene (96% isotacticity, melt index is 2.8g / 10min, melt index test conditions: melting temperature is 230°C, load weight is 2.16kg), 0.2wt% oil acid amide;

[0059] The second surface layer 3 is: 99.8wt% homopolypropylene (the isotacticity is 96%, the melt index test conditions: the melt index is 3g / 10min, the melting temperature is 230°C, and the load weight is 2.16kg), 0.2wt% Polymethyl meth...

Embodiment 3

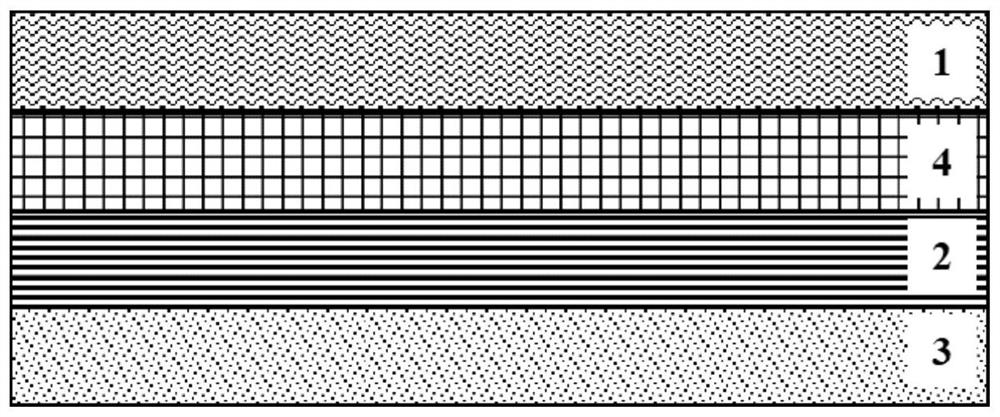

[0064] The polypropylene film for cold lamination composite film of present embodiment, the polypropylene film for cold lamination composite film of present embodiment, please refer to figure 2 , including a first surface layer 1, an adhesive layer 4, a core layer 2 and a second surface layer 3 arranged in sequence.

[0065] The first surface layer 1 is: 100wt% polymethylpentene copolymer (melt index is 4.6g / 10min, melt index test conditions: melting temperature is 230°C, load weight is 2.16kg);

[0066] Adhesive layer 4 is: 100wt% methylpentene-propylene copolymer (melt index is 10g / 10min, melt index test conditions: melting temperature is 230°C, load weight is 2.16kg);

[0067] Core layer 2 is: 99.8wt% homopolypropylene (98% isotacticity, melt index is 3g / 10min, melt index test conditions: melting temperature is 230°C, load weight is 2.16kg), 0.2wt% monohard fatty acid glycerides;

[0068] The second surface layer 3 is: 99.8wt% homopolypropylene (98% isotacticity, melt in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com