Preparation method of gold-containing three-layer micro-profile electrical contact material

A technology of electrical contact materials and micro-shape, applied in metal rolling, temperature control, etc., can solve the problems of complex manufacturing process, high performance and dimensional positioning accuracy, uneven heating, etc., and achieve stable and reliable electrical contact performance, High chemical stability and good dimensional consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

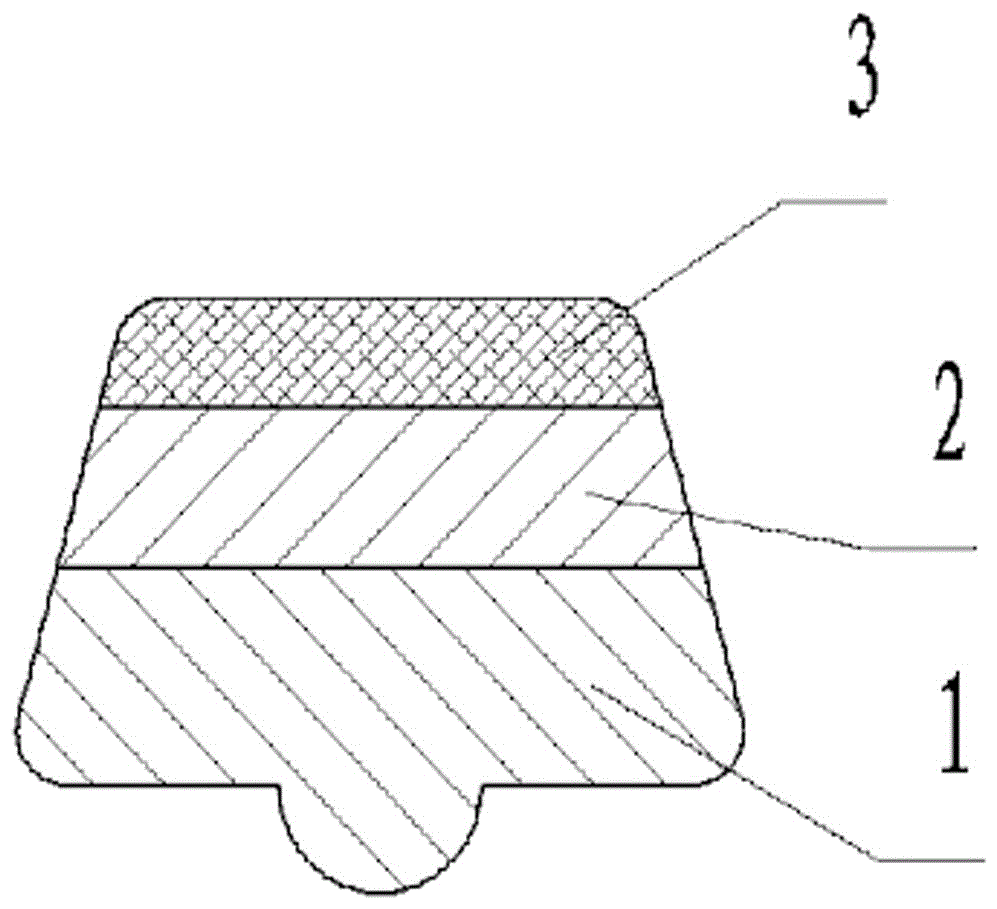

[0023] Embodiment 1: The preparation width is 1.1mm, the thickness of 24K pure gold layer is 2.5μm, the thickness of middle layer AgCu10 is 0.25mm, and the thickness of base layer MONEL400 is 0.15mm three-layer micro-shaped contact composite tape

[0024] Its preparation method has the following steps:

[0025] 1) Compounding for the first time

[0026] Using flat roll rolling and shearing, prepare Au with a thickness of 0.15mm and a width of 40mm; AgCu10 strips with a thickness of 2mm and a width of 40mm. After the above strips are pickled and polished, they are processed by warm rolling compound equipment Rolling and compounding, the protective gas is ammonia decomposition gas, heated by a resistance furnace, the compounding temperature is 500 degrees, and the compounding deformation is 50%. The above-mentioned compounded blank is subjected to a heat treatment at a heat treatment temperature of 600 degrees, and then rolled to 0.15mm on a four-roll rolling mill to obtain a A...

Embodiment 2

[0033] Embodiment 2: The thickness of Au is 1 μ m, the thickness of the middle layer AgNi10 is 0.12 mm, the thickness of the base layer CuNi30 is 0.1 mm, and the width is 0.5 mm. Three layers of gold-containing micro-shaped contact composite tape

[0034] Using flat roll rolling and shearing, prepare Au with a thickness of 0.1mm and a width of 50mm; AgNi10 strips with a thickness of 2.5mm and a width of 50mm. Carry out rolling and compounding, the protective gas is ammonia decomposition gas, heated by resistance furnace, the compounding temperature is 450 degrees, and the compounding deformation is 55%. The above-mentioned compounded blank is subjected to a heat treatment at a heat treatment temperature of 550 degrees, and then rolled to 0.1mm on a four-roll mill to obtain an Au / AgNi10 two-layer composite material blank;

[0035] 2) The second compound

[0036]Using flat roll rolling and shearing, prepare AgNi10 with a thickness of 0.26mm and a width of 7mm; a CuNi10 strip wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com