Centrifugal extraction machine drum resistant to strong acid corrosion

A centrifugal extractor, strong acid resistance technology, applied in the direction of liquid solution solvent extraction, etc., can solve the problems of the centrifugal extractor drum processing complex, not resistant to strong acid corrosion, etc., to achieve the effect of accurate size, size resistance to strong acid corrosion, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

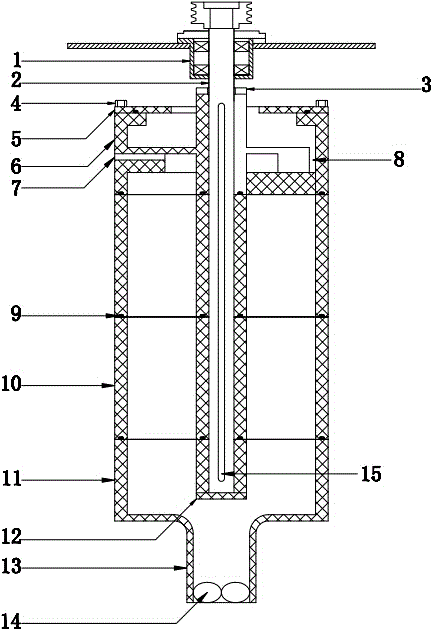

[0019] As shown in the drawings, the strong acid corrosion-resistant centrifugal extractor drum of this embodiment includes a bearing seat 1, a shaft 2, a lock nut 3, a bolt 4, a heavy phase weir plate 5, a dividing weir body 6, a light phase channel 7, Heavy phase channel 8, sealing ring 9, drum module 10, drum bottom 11, shaft cover 12, feed terminal 13, pump wheel 14, keyway 15.

[0020] Wherein, the weir body 6 , the drum module 10 , the drum bottom 11 , and the feed terminal 13 are fixed on the shaft 2 by the lock nut 3 .

[0021] Wherein, the shaft 2 is provided with a keyway 15, and the shaft 2 is made of carbon steel or other alloy steel.

[0022] Wherein, the weir body 6 , the drum module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com