A tar ammonia water separation tank operating system

A technology of tar ammonia water separation and operation system, applied in the field of tar ammonia water separation tank operation system, can solve the problems of high water content in tar, adverse effects of tar quality and coke oven production, insufficient precipitation of tar ammonia water, etc., and achieve stable interface and structural design Reasonable, the effect of improving the quality of ammonia water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

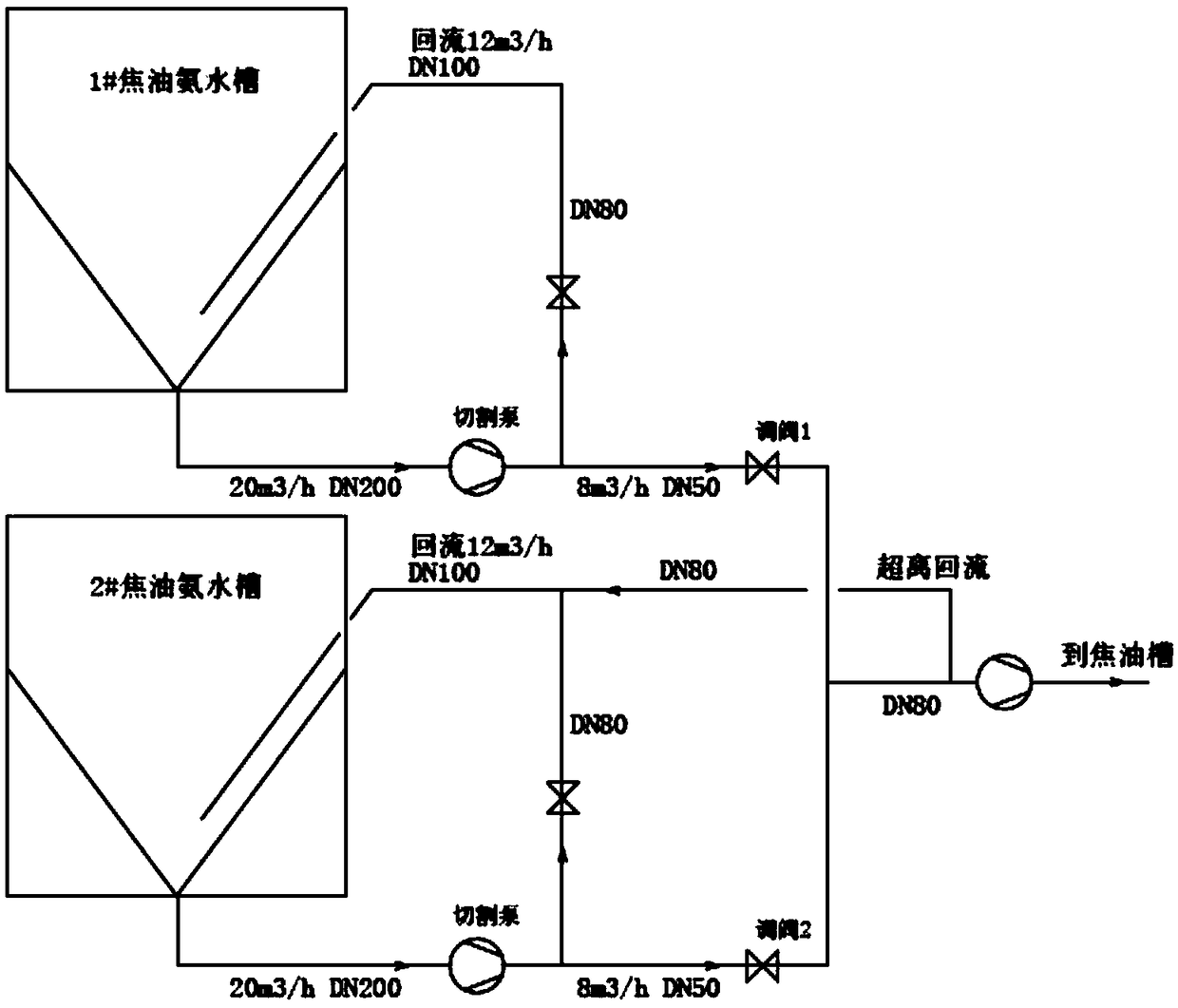

[0015] Such as figure 1 As shown, the operating system of the tar-ammonia water separation tank includes a tar-ammonia water tank, a cutting pump, a regulating valve, and a supercentrifuge, wherein there are two groups of the tar-ammonia water tank, a cutting pump, and a regulating valve, and one supercentrifuge.

[0016] The tank bottom of one tar ammonia water tank is connected with the supercentrifuge through a cutting pump and a regulating valve, and the tank bottom of the other tar ammonia water tank is connected with the supercentrifuge through another cutting pump and another regulating valve.

[0017] Two sets of tar ammonia water tanks are arranged side by side. Two sets of parallel treatment systems are formed, the two tar ammonia water tanks operate completely independently, and two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com