Conversion tank used in production of surface sizing agent

A technology of surface sizing agent and conversion tank, which is applied to chemical instruments and methods, mixers with rotating stirring devices, dissolution, etc., can solve the problems of inability to form operation lines, change surface properties, and high errors, and achieve High degree of automation, reduced steam output noise, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

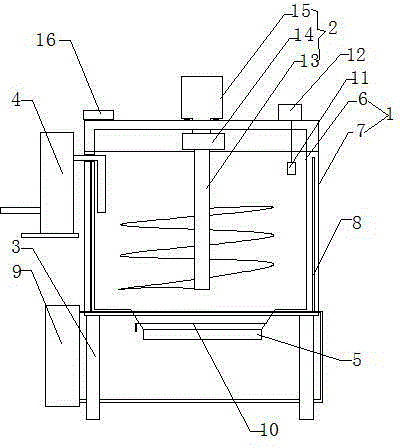

[0015] Such as figure 1 The shown conversion tank for surface sizing agent production includes a cavity 1, a mixer 2 arranged on the top of the cavity, a bracket 3 installed on the lower side of the cavity, and a pressure pump 4 installed on one side of the cavity, The output end of the pressure pump 4 is connected to the inner side of the cavity 1; the input end of the pressure pump 4 is connected to the dissolution tank (not shown); the bottom of the cavity 1 is provided with a discharge port 5; the cavity 1 is composed of The inner wall 6 and the outer wall 7 are composed; a steam heating pipeline 8 is arranged between the inner wall 6 and the outer wall 7; the steam heating pipeline 8 is connected to a Venturi steam heating mechanism 9 .

[0016] A locking plate 10 is provided at the discharge port 5 .

[0017] The mixer 2 is installed with the top of the cavity 1 through a flange.

[0018] A temperature probe 11 is arranged inside the cavity 1; the temperature probe 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com