Staged control method for camber based on the flat shape of the hot-rolled middle blank

A planar shape and segmented control technology, applied in the direction of rolling force/roll gap control, contour control, etc., can solve the problem of not considering the poor stiffness of the rolling mill, having no control function, and the central line of the intermediate billet cannot reflect the overall rotation of the intermediate billet, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

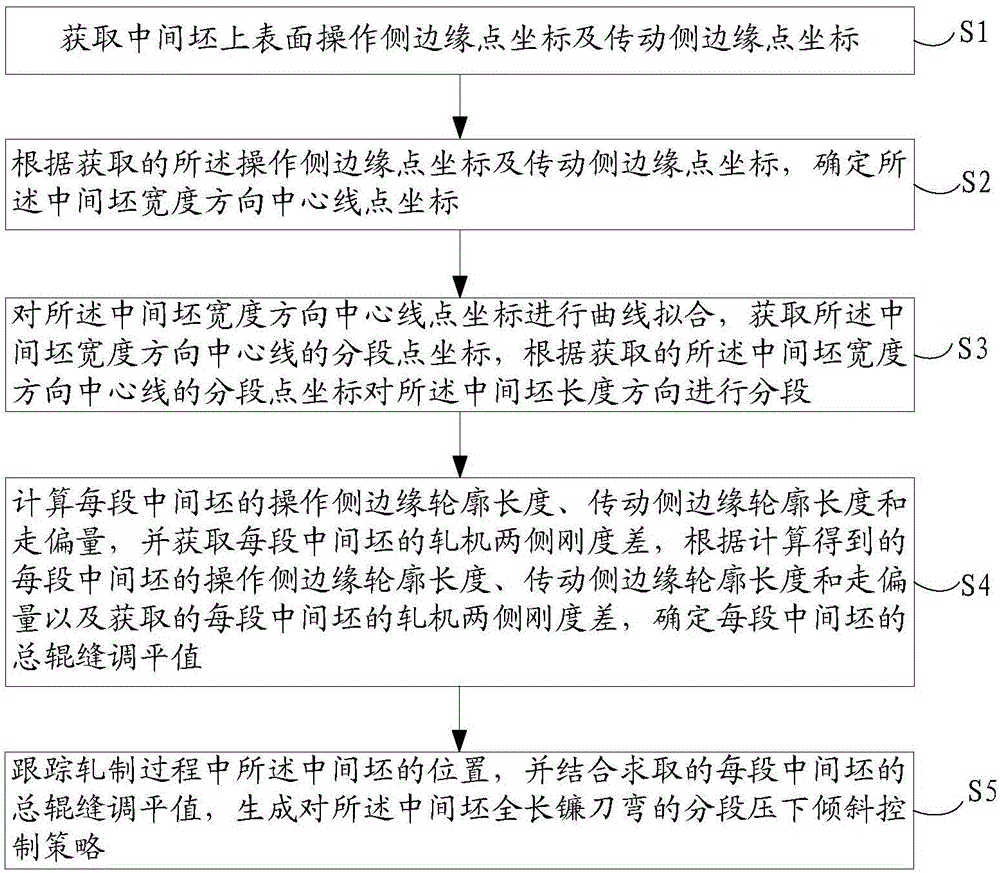

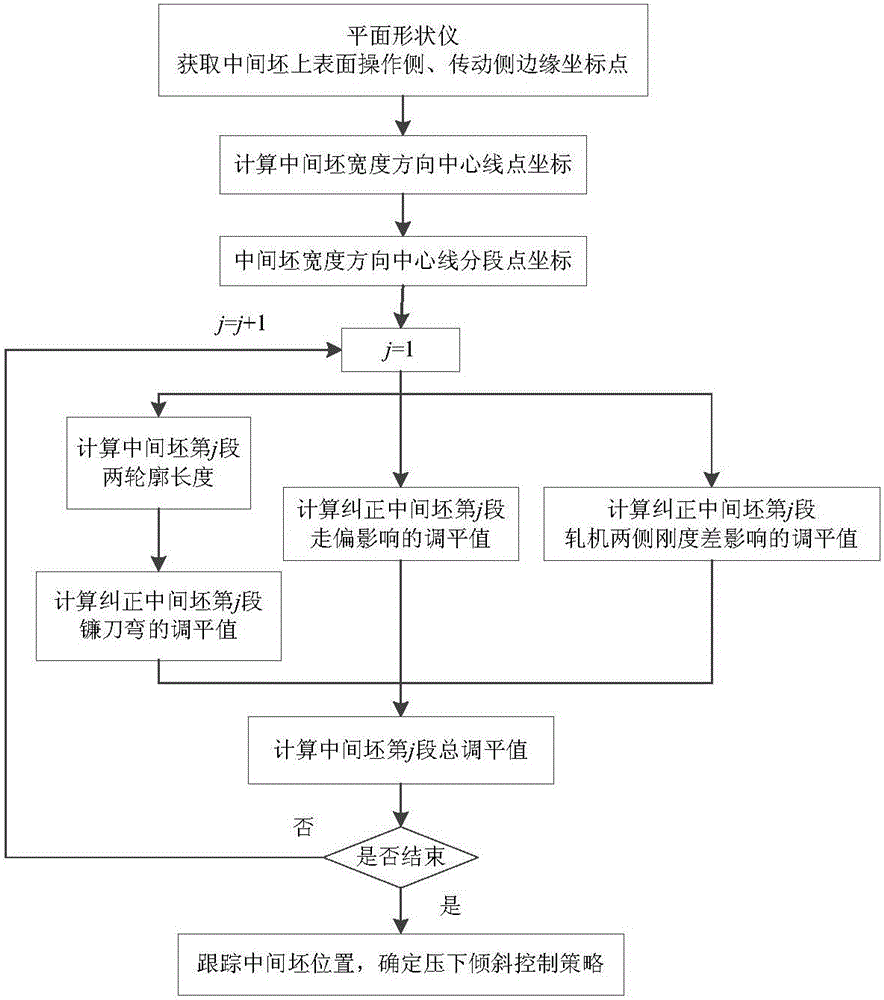

[0114] like figure 1 As shown, the camber segmentation control method based on the plane shape of the hot-rolled intermediate billet provided by the embodiment of the present invention includes:

[0115] S1, obtaining the coordinates of the edge point coordinates of the operation side and the edge point coordinates of the drive side of the upper surface of the intermediate billet;

[0116] S2. Determine the coordinates of the center line point in the width direction of the intermediate blank according to the acquired coordinates of the edge point on the operating side and the coordinates of the edge point on the transmission side;

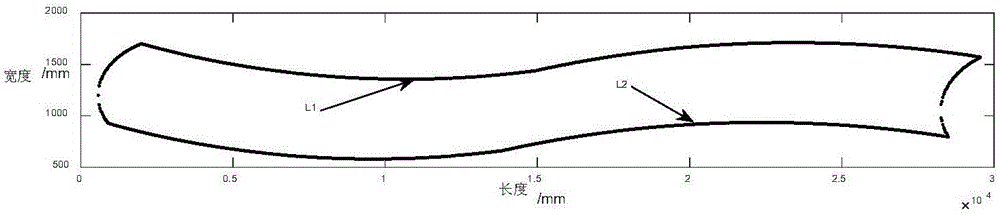

[0117] S3, performing curve fitting on the point coordinates of the center line in the width direction of the intermediate billet, obtaining the segment point coordinates of the center line in the width direction of the intermediate billet, and pairing the obtained segment point coordinates of the center line in the width direction of the intermedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com