Method and apparatus for rolling strip weld

A strip steel weld seam and rolling force technology, which is applied in the field of strip steel weld seam rolling, can solve problems such as broken strip and weld seam being rolled off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

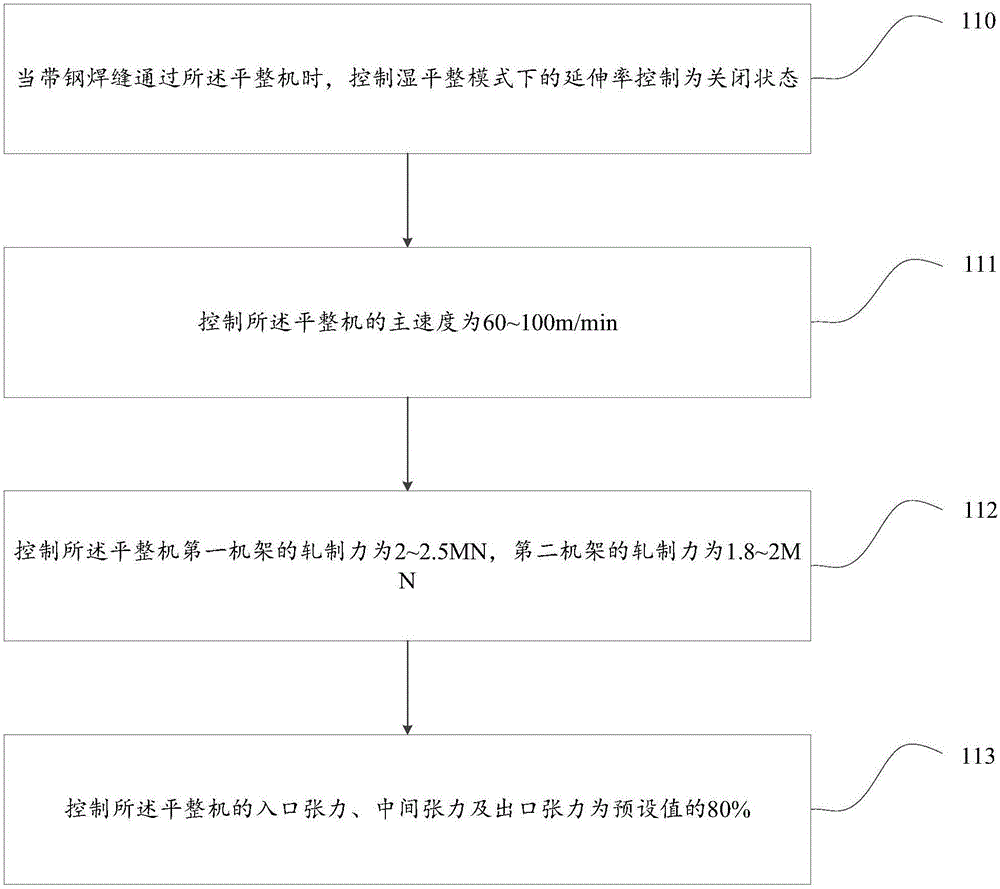

[0052] This embodiment provides a method for rolling strip welds, which is applied in the scene where the MTR system mistakenly believes that the holes on the strip are the punched holes of the welds, resulting in incorrect positioning of the strip welds, such as figure 1 As shown, the method includes the following steps:

[0053] Step 110, when the strip weld passes through the tempering machine, control the elongation control in the wet tempering mode to be off.

[0054] In this step, the wet leveling mode is to use leveling liquid for lubrication in the tempering machine frame, and the strip rolling deformation is small, and the goal to be controlled is to ensure constant elongation by adjusting the rolling force.

[0055] When the material tracking system detects that there are two punch holes on a section of strip steel, it adjusts the skin pass machine to the state of passing the weld seam, and sends an alarm prompt to the staff. When describing the skin pass machine, t...

Embodiment 2

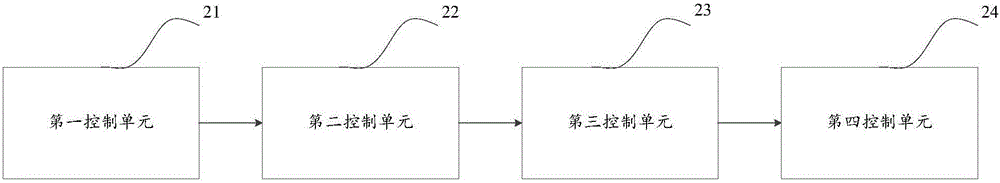

[0069] Corresponding to Embodiment 1, this embodiment also provides a device for rolling strip welds, such as figure 2 As shown, the device includes: a first control unit 21, a second control unit 22, a third control unit 23 and a fourth control unit 24; wherein,

[0070] When the strip weld passes through the tempering machine, the first control unit 21 is used to control the elongation control in the wet leveling mode to be closed; specifically, the wet leveling mode is used for lubrication in the tempering machine frame Tempering liquid, strip rolling deformation is small, the goal of control is to ensure constant elongation by adjusting rolling force. When the material tracking system detects that there are two punch holes on a section of strip steel, it adjusts the skin pass machine to the state of passing the weld seam, and sends an alarm prompt to the staff. When describing the skin leveling machine, the staff clicks the weld seam button once through the man-machine i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com